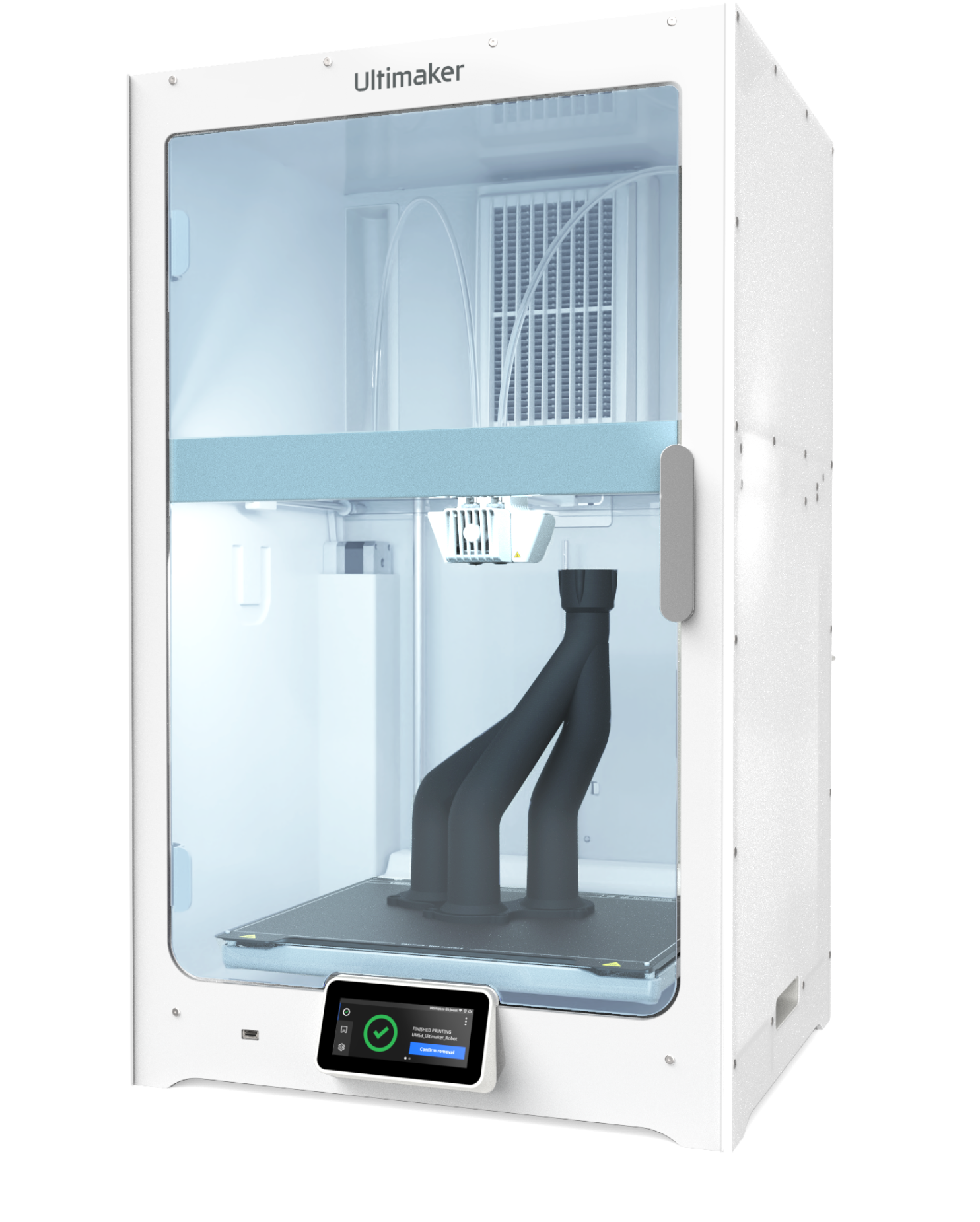

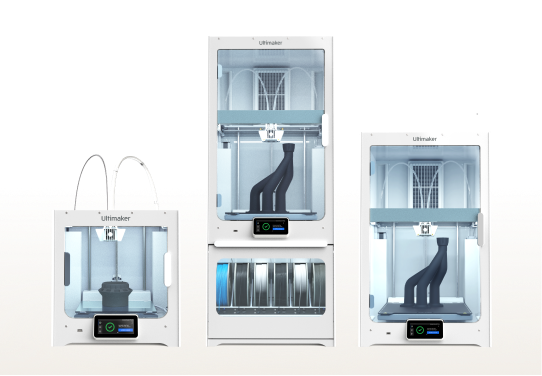

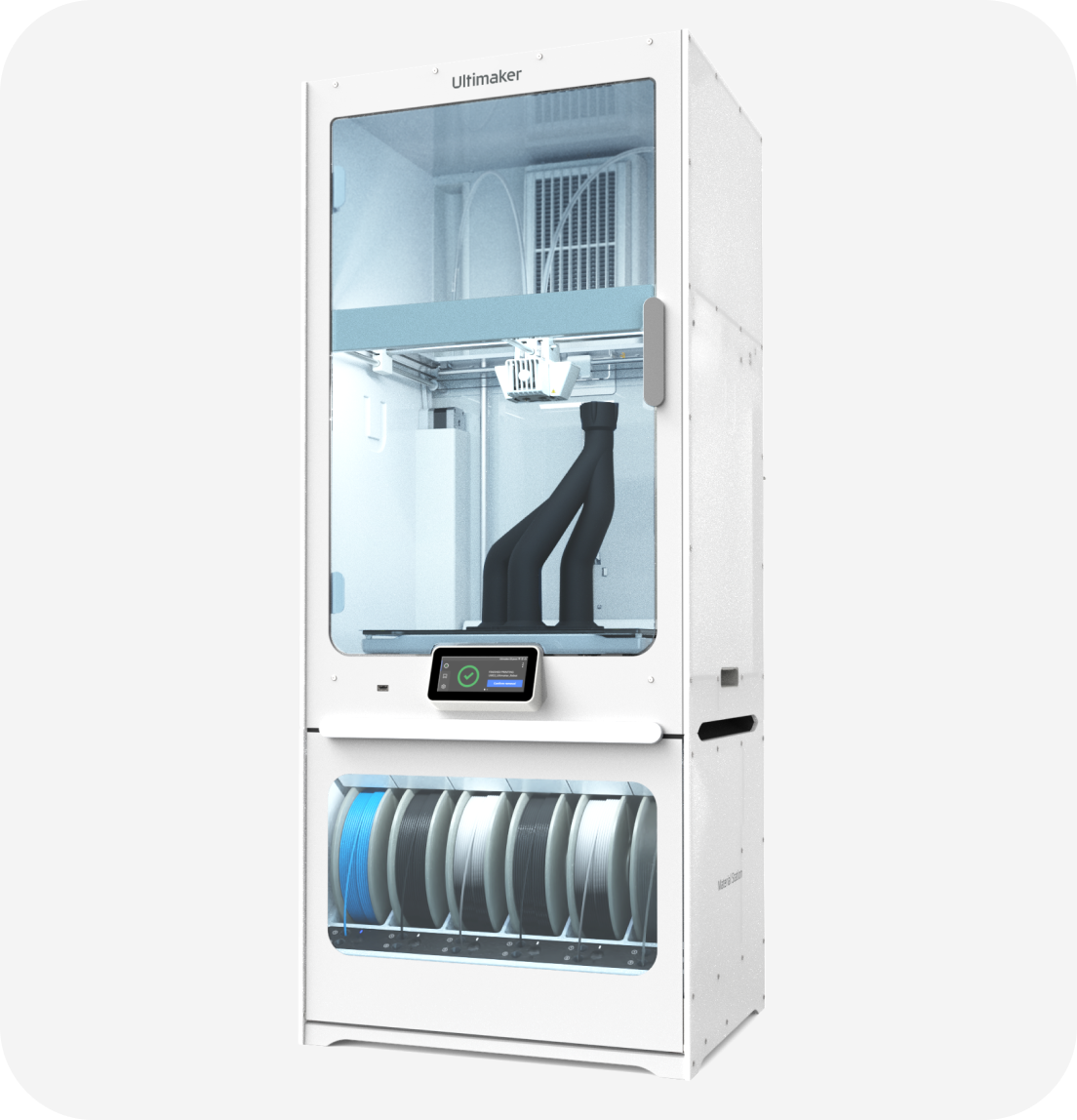

Easy breathing.

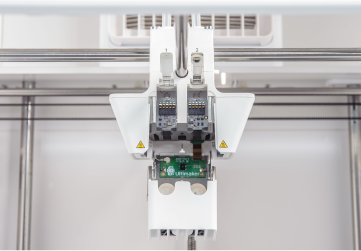

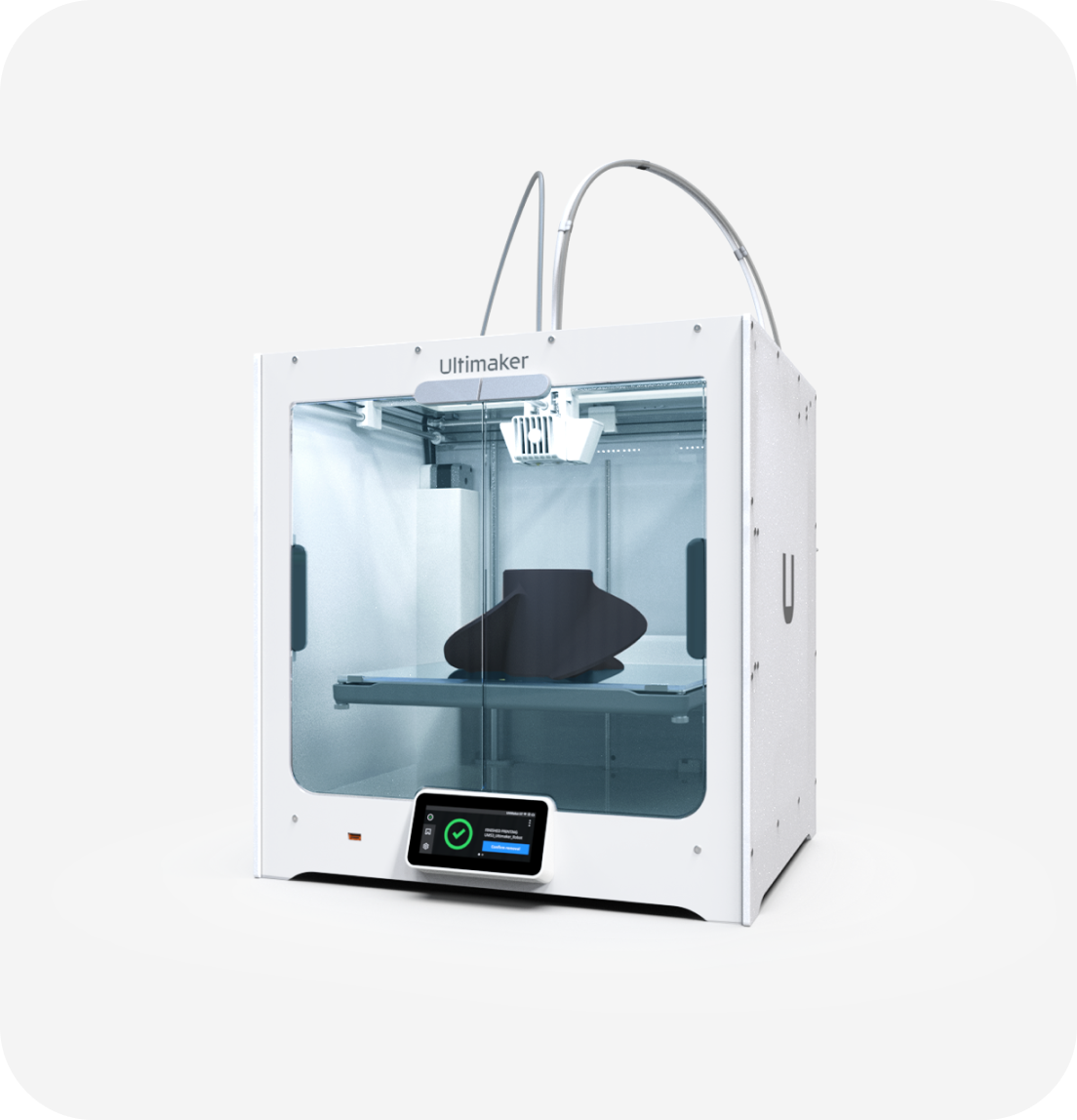

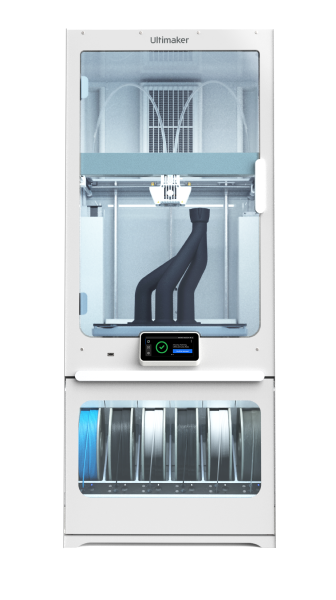

Integrated Air Manager

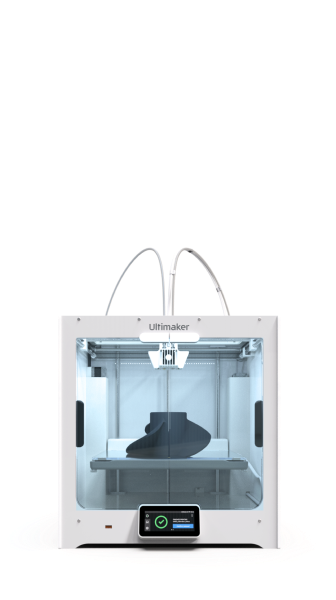

Not only does this increase air quality peace of mind... It also boosts print quality thanks to its fully enclosed build chamber and single glass door.

Independently tested

Remove up to

95%

of ultrafine particles from every print.*

* Tested by Fraunhofer WKI. Only including UltiMaker materials.