S series 3D-Drucker

Design. Drucken. Wiederholen. Schalten Sie hochwertige Anwendungen frei und reduzieren Sie Kosten mit unserem professionellen 3D-Druck-Ökosystem.

Unlimited application potential.

Specialized for engineering applications.

High-performance and certified materials

Over 280 materials to choose from.

From polymers to composites to metals.

Optimize production processes

Keeping defense assets operational

A 3D Printer Platform Made for Education

Take your designs to the next level

Explore our support content

Pricing or financing options

Press and general inquiries

Contact our support team directly

UltiMaker Factor 4, unser neuer industrietauglicher 3D-Drucker, optimiert die Produktion, vereinfacht die Prozesse und hält den Betrieb am Laufen.

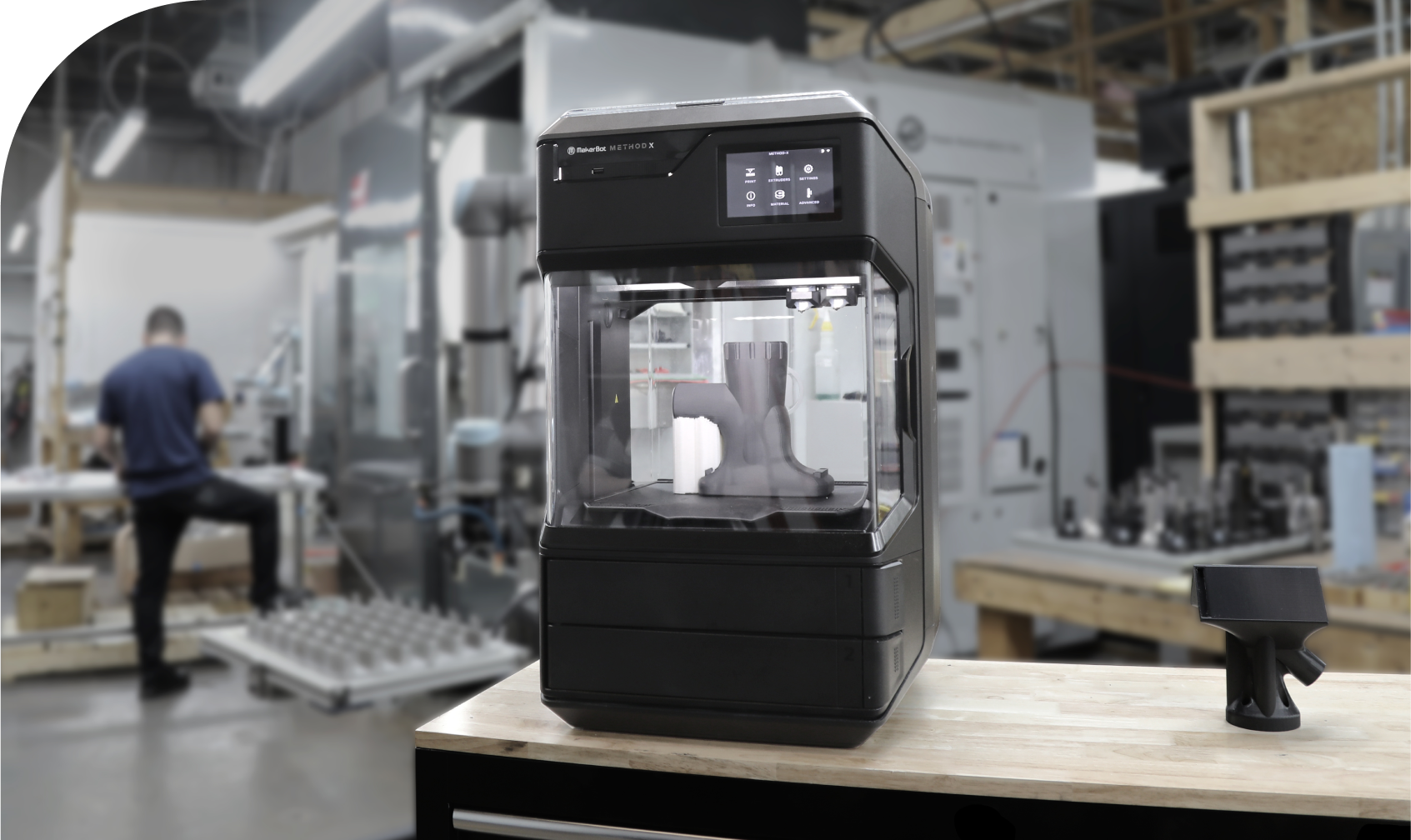

Method XL liefert präzise, ingenieurtechnische ABS-Prototypen, angetrieben von seiner beheizten Bauplatte und Kammer. Es garantiert starke Schichtadhäsion, ermöglicht komplexe Geometrien mit wasserlöslichen Stützen und schützt die Luftqualität mit seinem eingebauten HEPA-Filter.

Design. Drucken. Wiederholen. Erschließen Sie hochwertige Applicaties und reduzieren Sie Kosten mit unserem professionellen 3D-Druck-Ökosystem.

Factor 4

Method XL

S series

Design. Drucken. Wiederholen. Schalten Sie hochwertige Anwendungen frei und reduzieren Sie Kosten mit unserem professionellen 3D-Druck-Ökosystem.

Die Stärke der S-Serie liegt in ihrer Vielseitigkeit. Entdecken Sie neue 3D-Druckanwendungen mit der größten Materialauswahl auf dem Markt – sie sind perfekt für Prototypen und Fertigungshilfen aller Größen. Sie verwenden 2,85 mm Filament und entfesseln die volle Leistung von UltiMaker Cura, um Ihren Arbeitsablauf zu vereinfachen.

Learn more

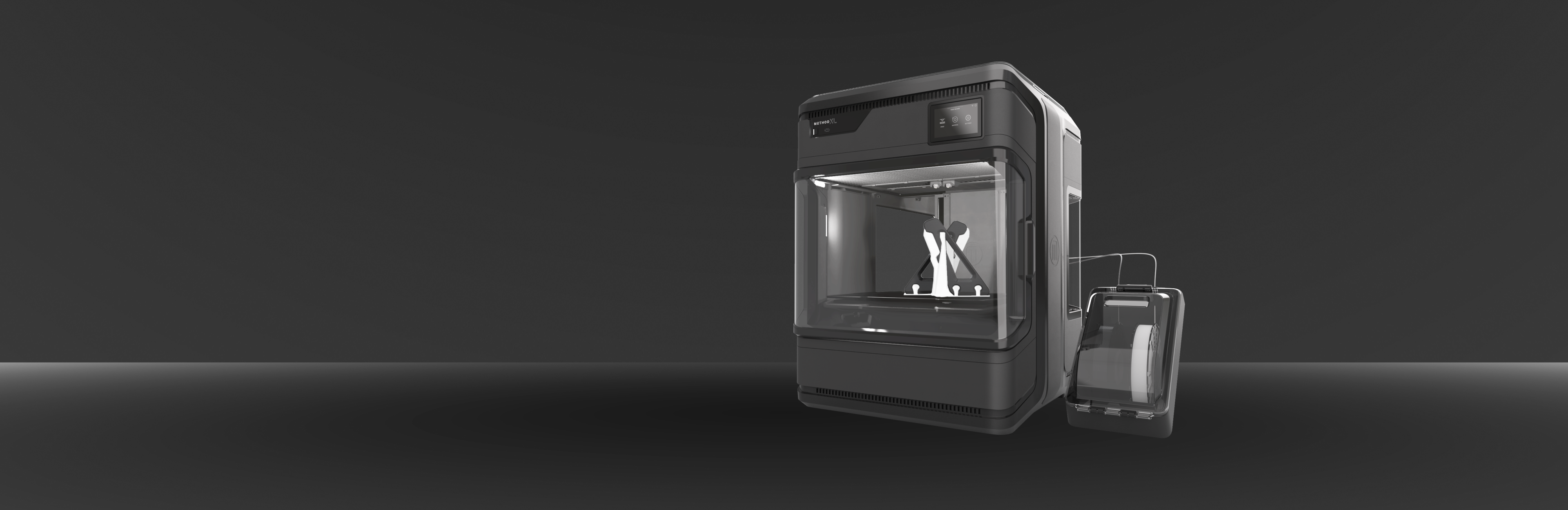

Die Method-Serie ist für die hochwertige Produktion von Werkzeugen und Endverbraucherteilen konzipiert. Ihre aktiv beheizten Bauräume, der Direktantrieb und der starre Metallrahmen erleichtern den 3D-Druck eines spezifischen Bereichs von technischen Materialien mit hoher Wiederholgenauigkeit und Maßhaltigkeit unter Verwendung von 1,75 mm Filament.

Die Method-Serie ist für die hochwertige Produktion von Werkzeugen und Endverbraucherteilen konzipiert. Ihre aktiv beheizten Bauräume, der Direktantrieb und der starre Metallrahmen erleichtern den 3D-Druck eines spezifischen Bereichs von technischen Materialien mit hoher Wiederholgenauigkeit und Maßhaltigkeit unter Verwendung von 1,75 mm Filament.

Learn more

Die größte Auswahl an hochwertigen 3D-Druckerfilamenten auf dem Markt. Speziell für S series und Method series 3D-Drucker entwickelt, um Ergebnisse für nahezu jede denkbare Anwendung zu erzielen.

S series materials

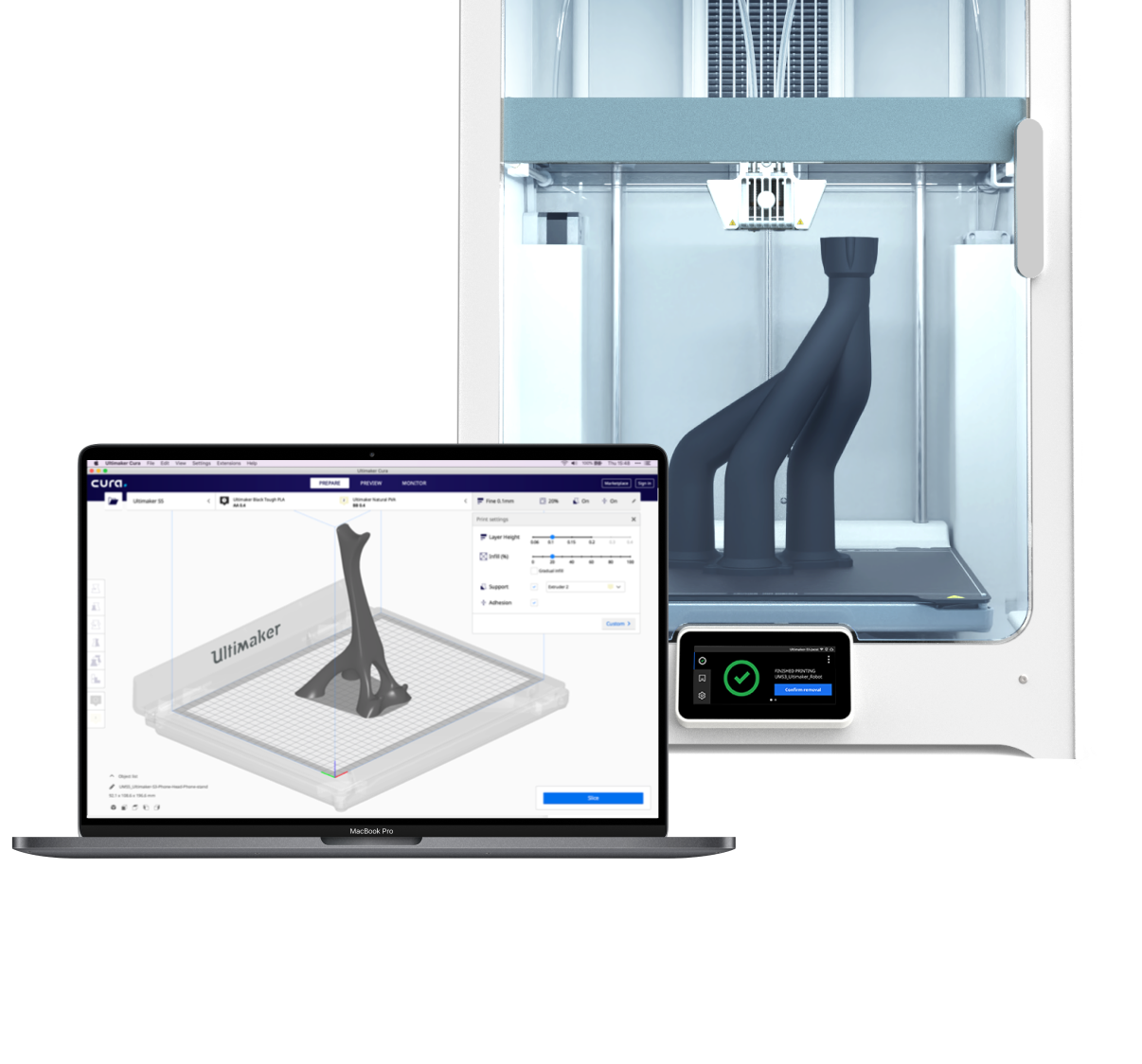

Vertraut von Millionen von Nutzern, ist UltiMaker Cura die weltweit beliebteste 3D-Drucksoftware. Bereiten Sie Drucke mit nur wenigen Klicks vor, integrieren Sie sie mit CAD-Software für einen einfacheren Workflow oder tauchen Sie in benutzerdefinierte Einstellungen für eine tiefergehende Kontrolle ein.

Download for free