Impresoras 3D de la serie S

Diseño. Impresión. Repetición. Desbloquee aplicaciones de alto valor y reduzca costos con nuestro ecosistema profesional de impresión 3D.

Unlimited application potential.

Specialized for engineering applications.

Over 280 materials to choose from.

From polymers to composites to metals.

Optimize production processes

Keeping defense assets operational

A 3D Printer Platform Made for Education

Take your designs to the next level

Explore our support content

Pricing or financing options

Press and general inquiries

Descubra las más recientes soluciones de impresión 3D de UltiMaker: Impresoras 3D de escritorio, software y materiales para una producción optimizada e innovación ilimitada.

Diseño. Impresión. Repetición. Desbloquee aplicaciones de alto valor y reduzca costos con nuestro ecosistema profesional de impresión 3D.

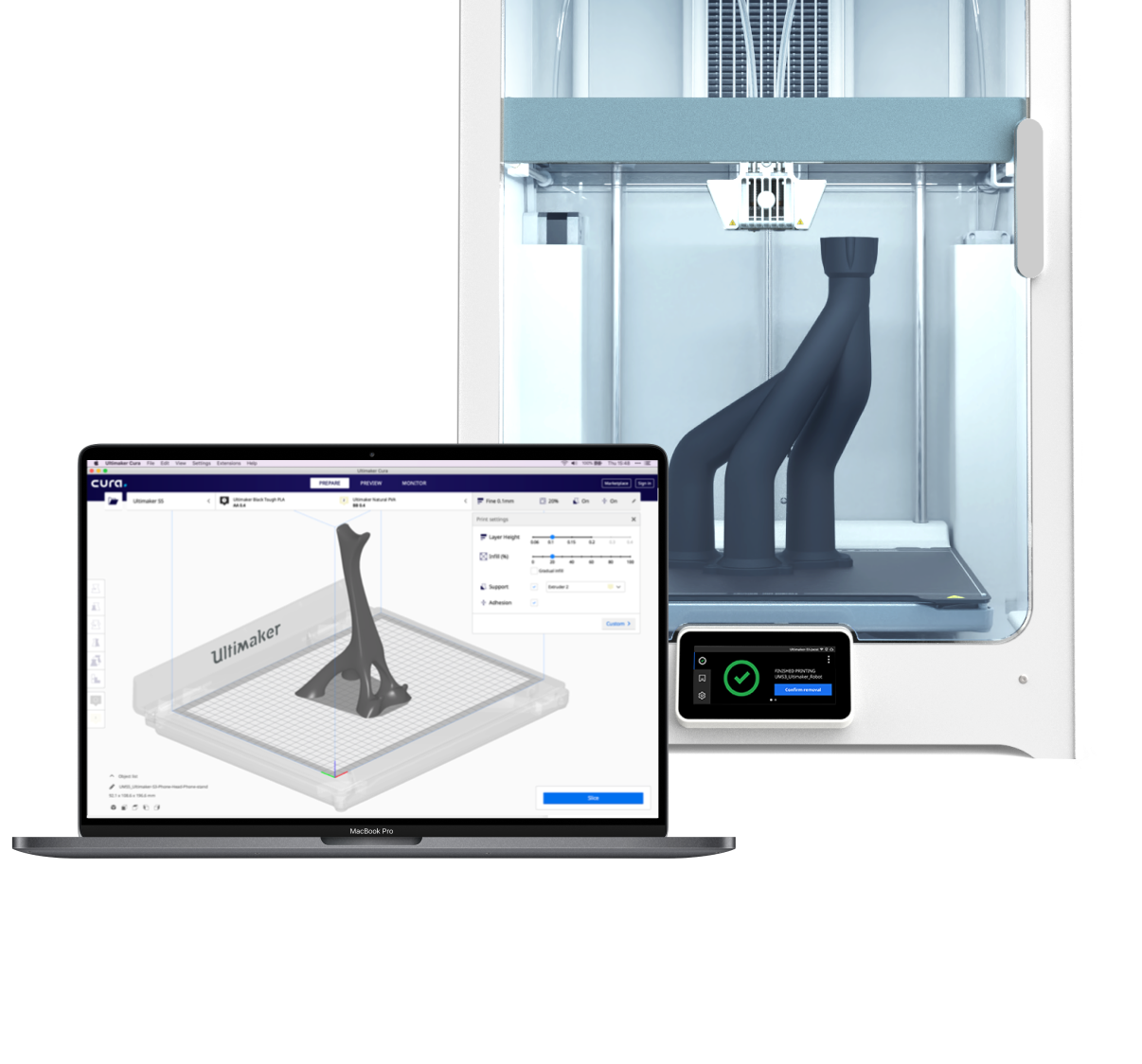

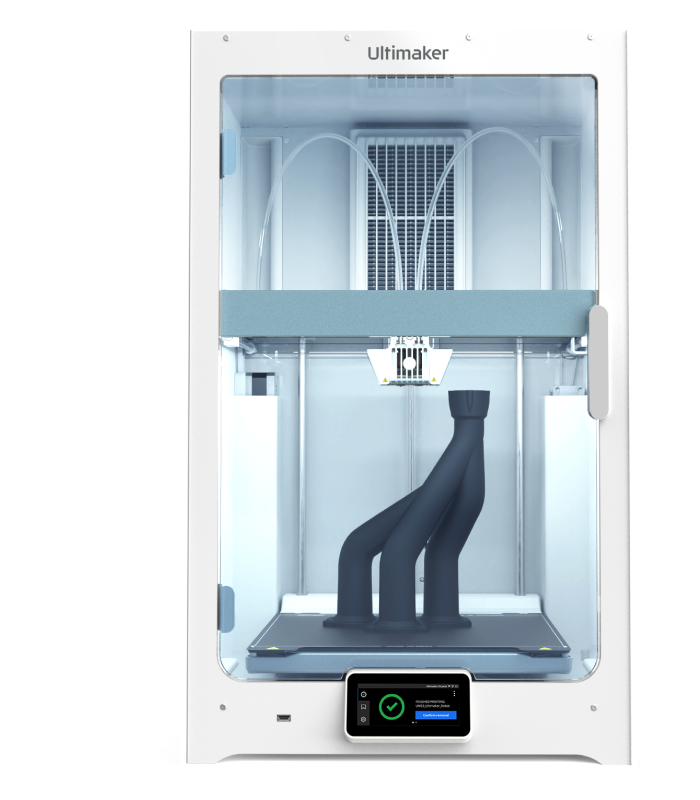

La potencia de la S Series radica en su versatilidad. Explore nuevas aplicaciones de impresión 3D utilizando la más amplia selección de materiales en el mercado, lo que las hace perfectas para la creación de prototipos y ayudas de fabricación de todos los tamaños. Utilizan filamento de 2.85 mm y desbloquean todo el poder de UltiMaker Cura para simplificar su flujo de trabajo.

Learn more

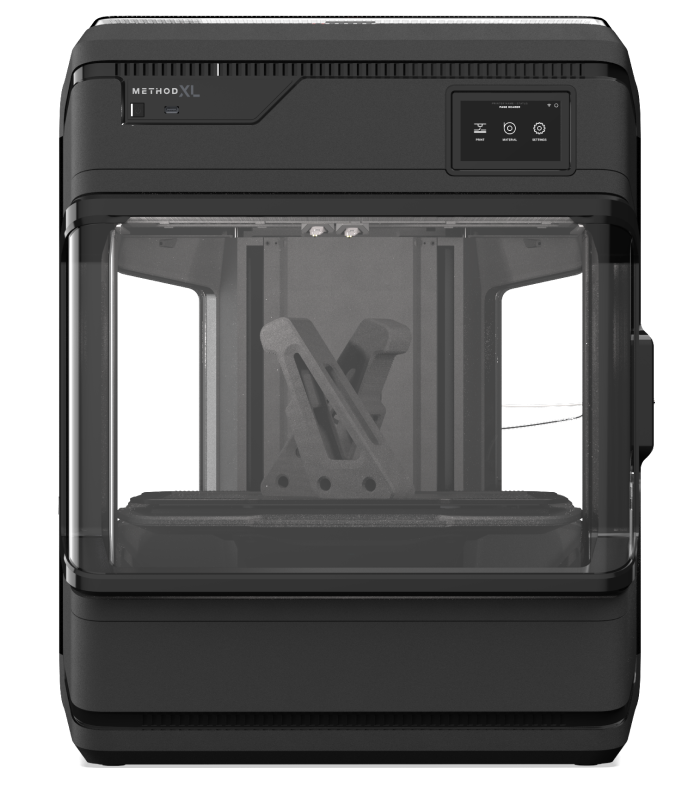

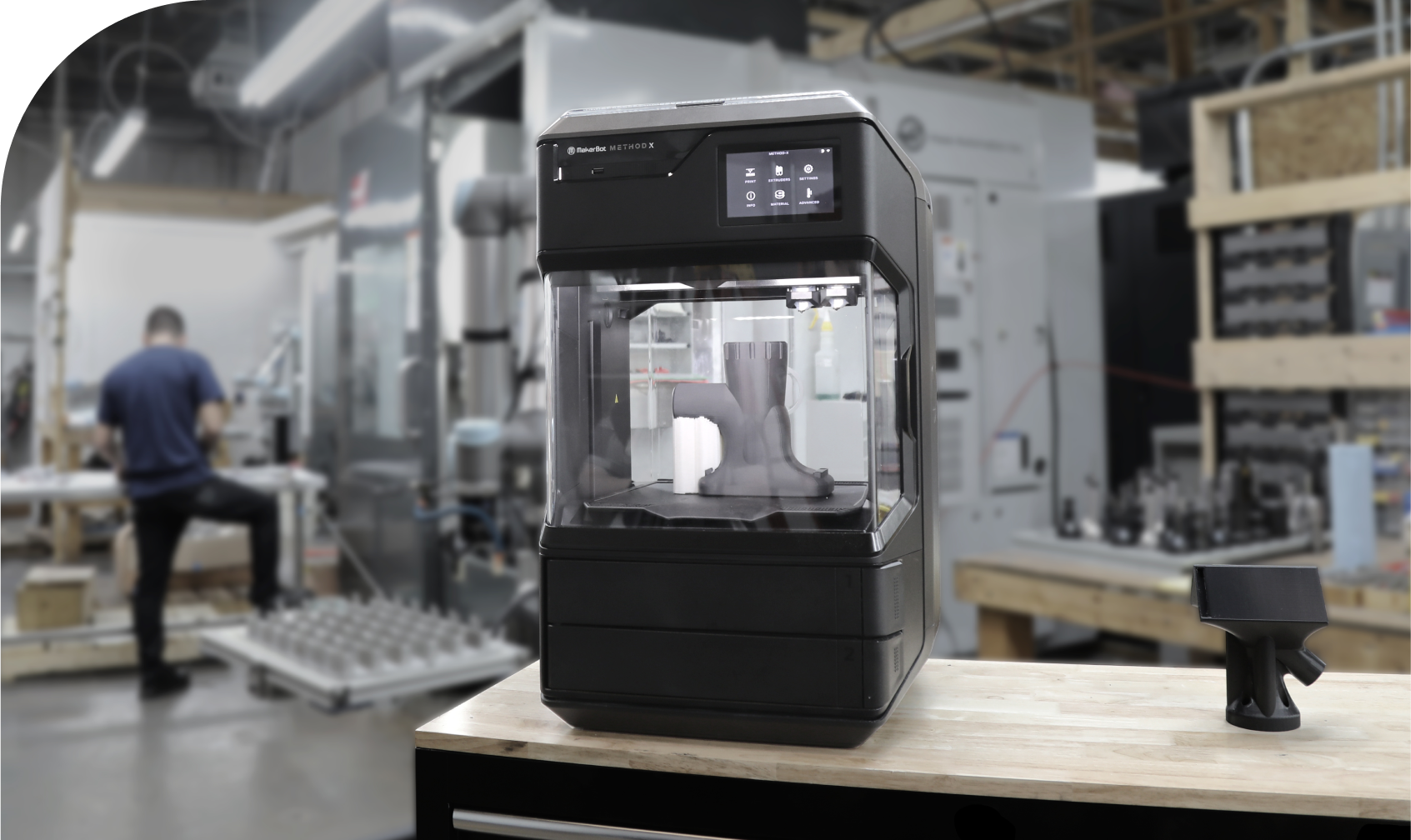

La serie Method está diseñada para la producción de alta calidad de herramientas y piezas de uso final. Sus cámaras de construcción con calefacción activa, transmisión directa y marco metálico rígido facilitan la impresión 3D de una gama específica de materiales de grado de ingeniería con alta repetibilidad y precisión dimensional utilizando filamento de 1.75 mm.

La Method Series está diseñada para la producción de alta calidad de herramientas y piezas de uso final. Sus cámaras de construcción con calefacción activa, transmisión directa y marco metálico rígido facilitan la impresión 3D de un rango específico de materiales de grado ingenieril con alta repetibilidad y precisión dimensional utilizando filamento de 1.75 mm.

Learn more

La más amplia selección de filamentos para impresoras 3D de alta calidad en el mercado. Formulados para las impresoras 3D de la serie S y la serie Method para lograr resultados en casi cualquier aplicación que pueda imaginar.

S series materials

Confiado por millones de usuarios, UltiMaker Cura es el software de impresión 3D más popular del mundo. Prepare impresiones con unos pocos clics, intégrelo con software CAD para un flujo de trabajo más fácil, o sumérjase en configuraciones personalizadas para un control profundo.

Descargue gratuitamente