Eventuri develops car intake systems for top-tier performance cars such as the Audi RS range and the M-Power BMW range. 3D printing allows them to be flexible in the design process, and gives them the ability to functional and fit test their 3D printed intakes. With 3D printing, Eventuri can run quick iterations of their intakes, allowing them to reach a perfect design at great speed.

Performance car intakes

Bilal Mahmood founded Eventuri as he saw a gap in the automotive market for high-quality intake systems. The Ultimaker Original that he had bought for personal use was eventually also used in the company. Since then, Eventuri has switched to the Ultimaker 2+ and Ultimaker 2 Extended+ for prototyping their intake systems. They currently supply the Audi RS range and M-Power BMW range, and are also looking at supercars like Lamborghini, Porsche, and Ferrari.

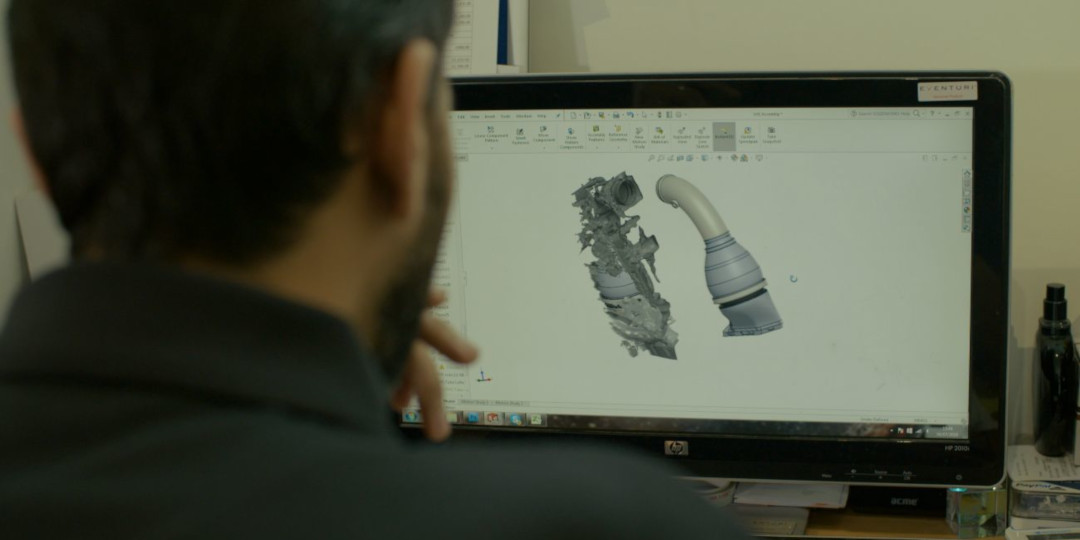

3D printing complex intake designs

The design process for the intakes is really complex, as the shapes are all very organic. 3D printing makes it possible to quickly turn these complex designs into physical prototypes, allowing Eventuri to move from initial concept to final design in a short period of time, but with great flexibility.

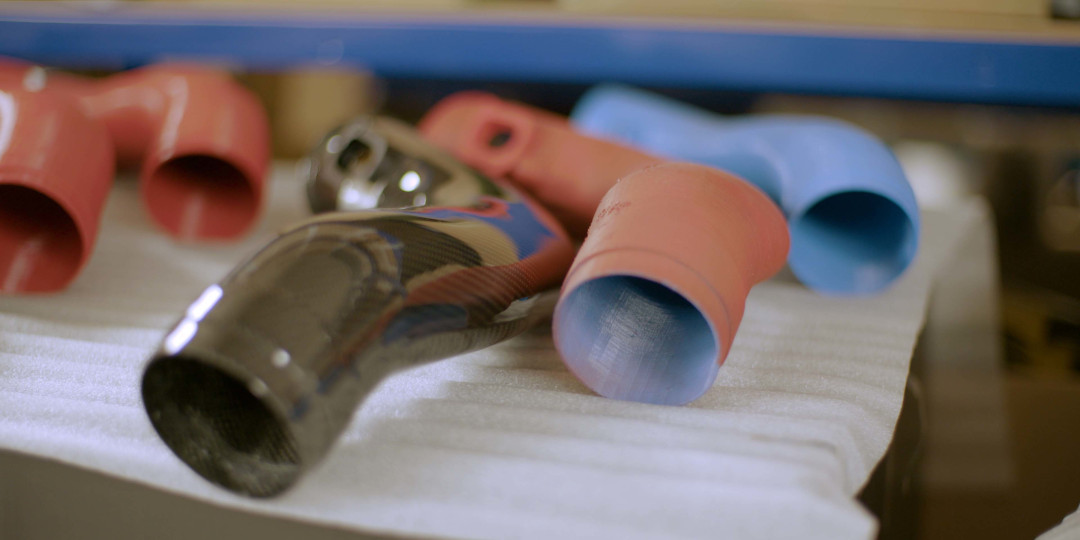

One of Eventuri's intake designs

Several iterations of an intake duct for the BMW M4

With 3D printing, Eventuri is also able to functional and fit test the 3D printed intakes before developing the final carbon-fibre parts. As prototyping makes up such a crucial part of the workflow, 3D printing has become a vital asset for Eventuri's intake development process. As Bilal put it:

3D printing allows us to be flexible, to really nail the design, and get down to the perfect solution.

A 3D printed intake prototype for the Audi RS 5

As this case illustrates, 3D printing can greatly enhance the development process of parts used in the automotive industry. Apart from providing quick iterations of a specific design, 3D printed parts can also be used for functional and fit testing. Discover the possibilities of 3D printing in the automotive industry by checking out our explore pages: