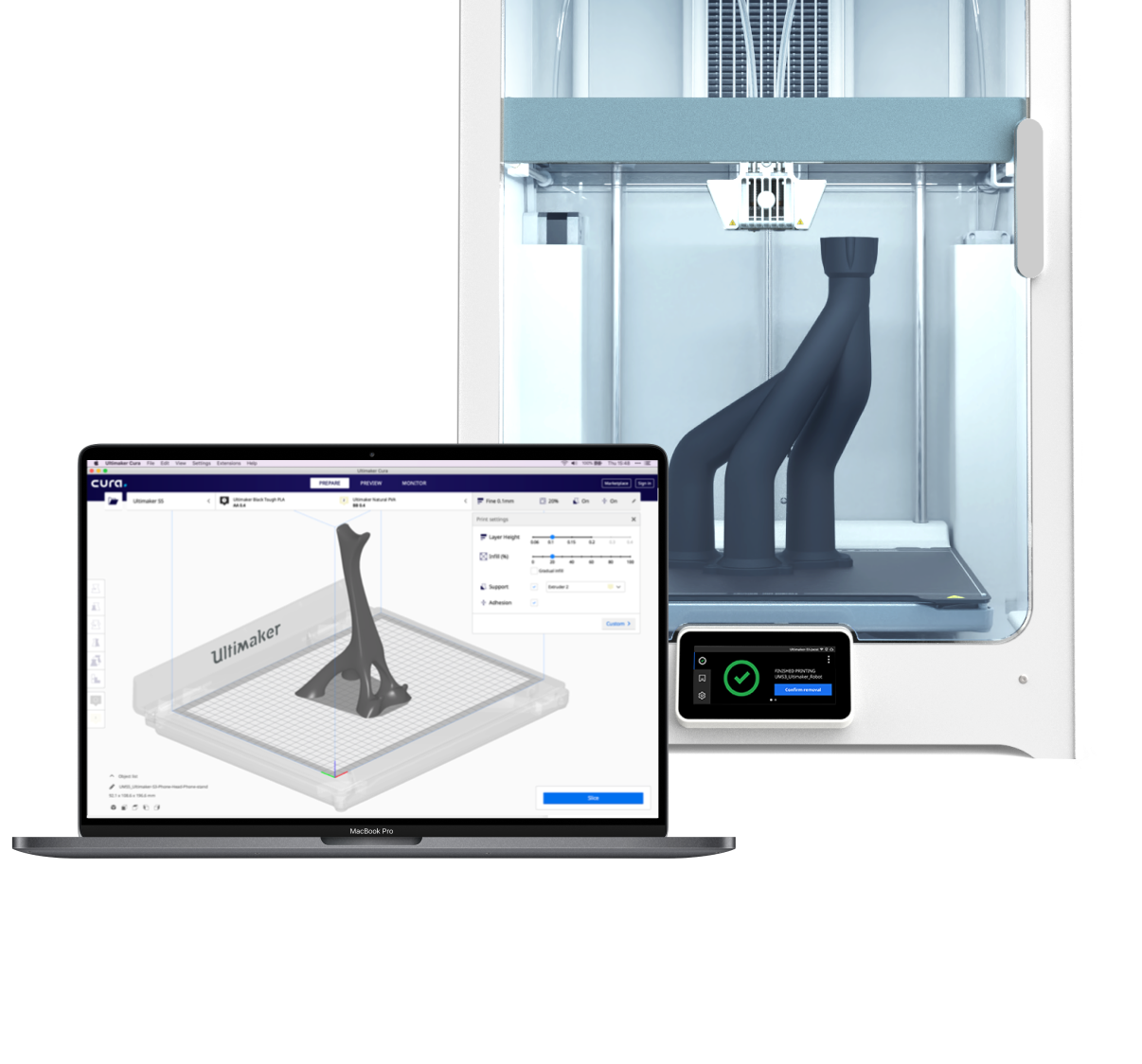

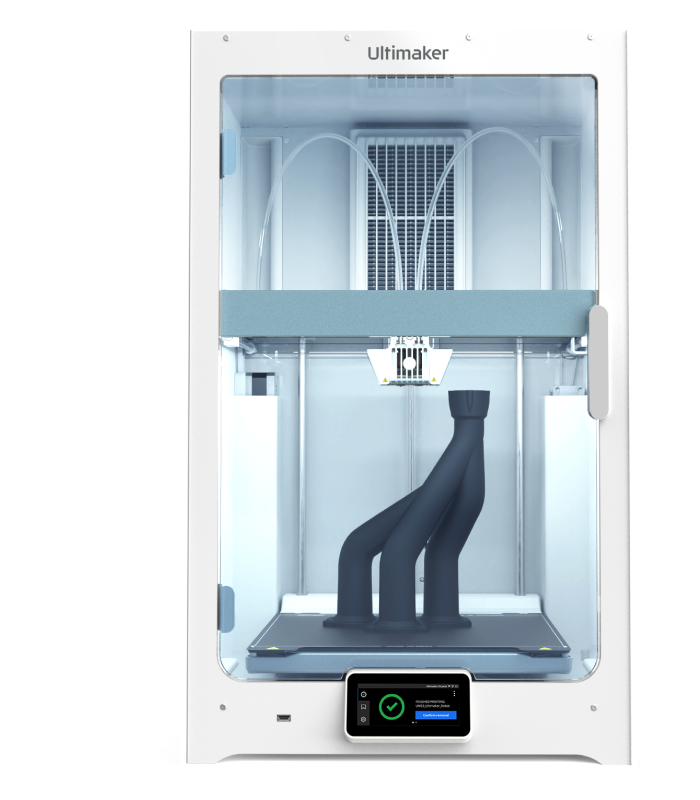

S series 3D-printers

Ontwerp. Print. Herhaal. Ontgrendel hoogwaardige applicaties en verlaag kosten met ons professionele 3D-printecosysteem.

Unlimited application potential.

Specialized for engineering applications.

Over 280 materials to choose from.

From polymers to composites to metals.

Optimize production processes

Keeping defense assets operational

A 3D Printer Platform Made for Education

Take your designs to the next level

Explore our support content

Pricing or financing options

Press and general inquiries

Ontdek de nieuwste 3D-printoplossingen van UltiMaker: Desktop 3D-printers, software en materialen voor gestroomlijnde productie en onbeperkte innovatie.

Ontwerp. Print. Herhaal. Ontgrendel hoogwaardige applicaties en verlaag kosten met ons professionele 3D-printecosysteem.

De kracht van de S series ligt in zijn veelzijdigheid. Ontdek nieuwe 3D-print applicaties met de breedste keuze aan materialen op de markt – waardoor ze perfect zijn voor het prototypen en vervaardigen van hulpmiddelen van alle formaten. Ze gebruiken 2,85 mm filament en ontsluiten de volledige kracht van UltiMaker Cura om uw workflow te vereenvoudigen.

Learn more

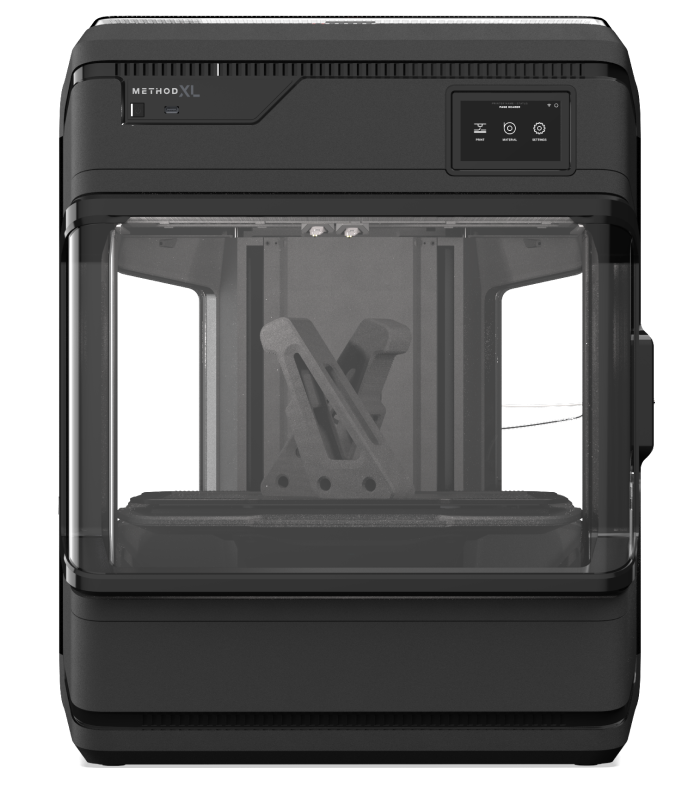

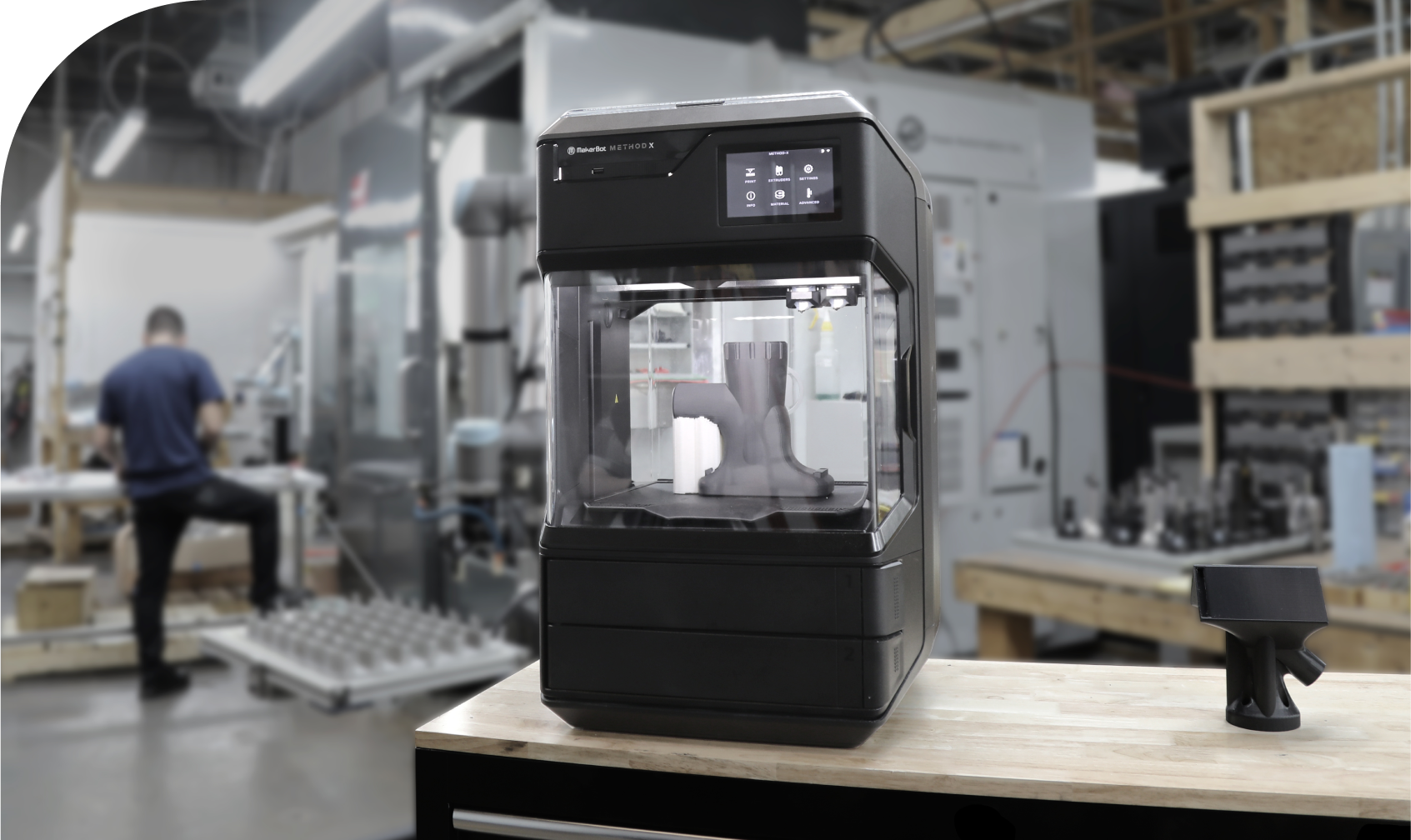

De Method series is ontworpen voor de hoogwaardige productie van gereedschappen en eindgebruiksonderdelen. Hun actief verwarmde bouwkamers, directe aandrijving en stijve metalen frame maken het eenvoudig om een specifiek assortiment van technische materialen te 3D-printen met hoge herhaalbaarheid en dimensionale nauwkeurigheid met behulp van 1,75 mm filament.

Gespecialiseerd voor technische applicaties.

De Method series is ontworpen voor de hoogwaardige productie van gereedschappen en eindproducten. Hun actief verwarmde bouwkamers, directe aandrijving en stijve metalen frame maken het eenvoudig om een specifiek bereik van technische materialen te 3D-printen met hoge herhaalbaarheid en dimensionale nauwkeurigheid met behulp van 1,75 mm filament.

Learn more

De ruimste keuze aan hoogwaardige 3D-printerfilamenten op de markt. Geformuleerd voor de S series en Method series 3D-printers om resultaten te bereiken voor bijna alle applicaties waar u aan kunt denken.

S series materials

Vertrouwd door miljoenen gebruikers, is UltiMaker Cura 's werelds meest populaire 3D-printsoftware. Bereid afdrukken voor met een paar klikken, integreer met CAD-software voor een eenvoudigere workflow, of duik in aangepaste instellingen voor diepgaande controle.

Download for free