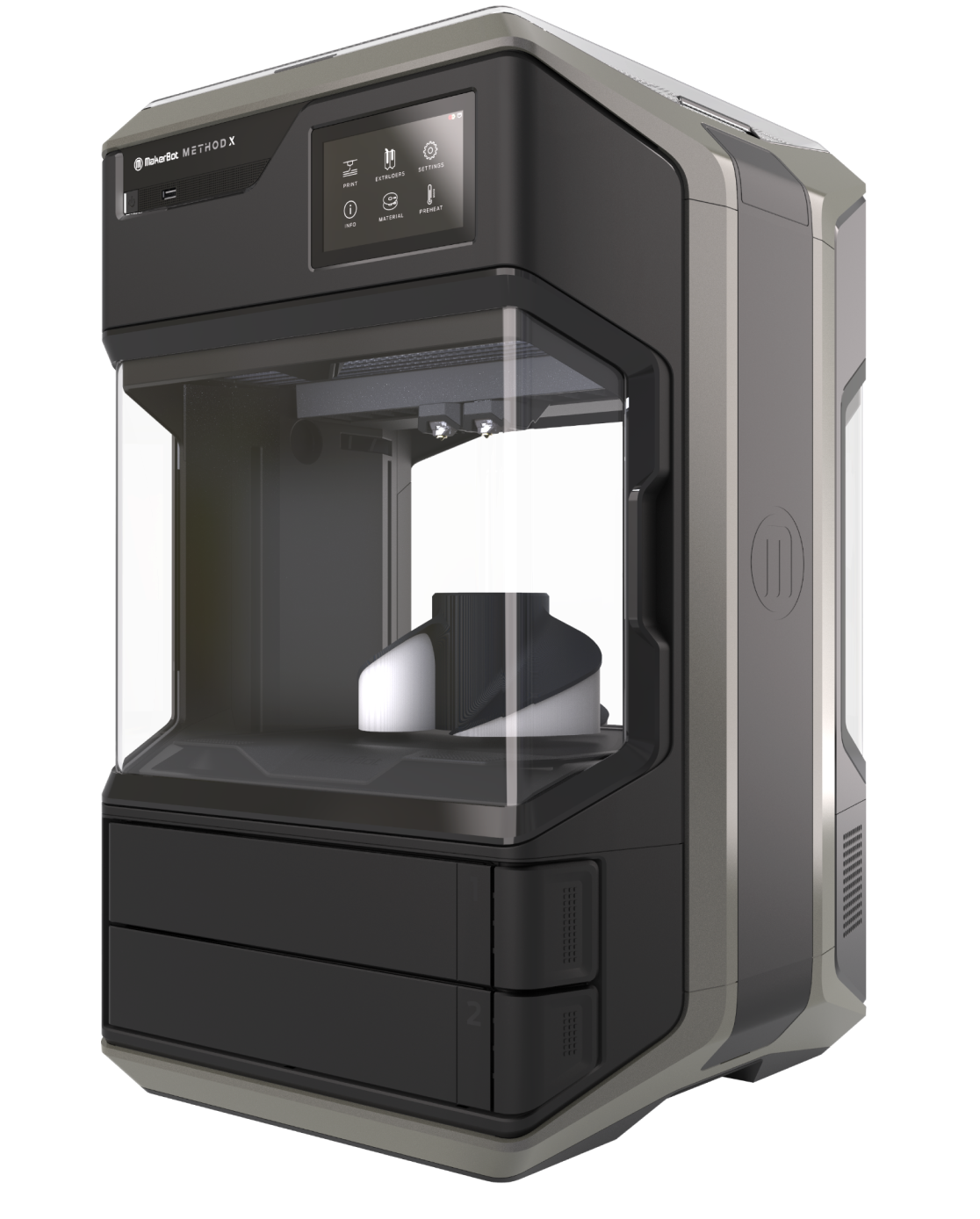

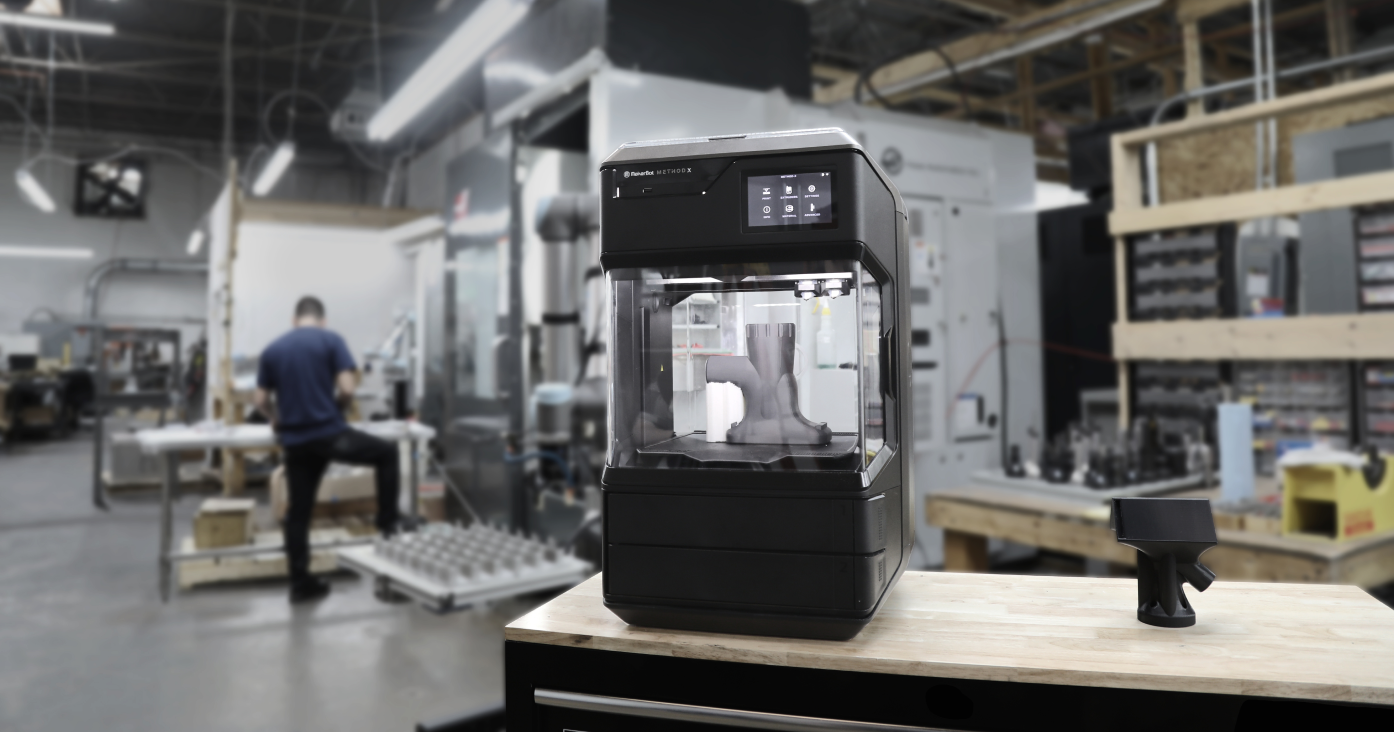

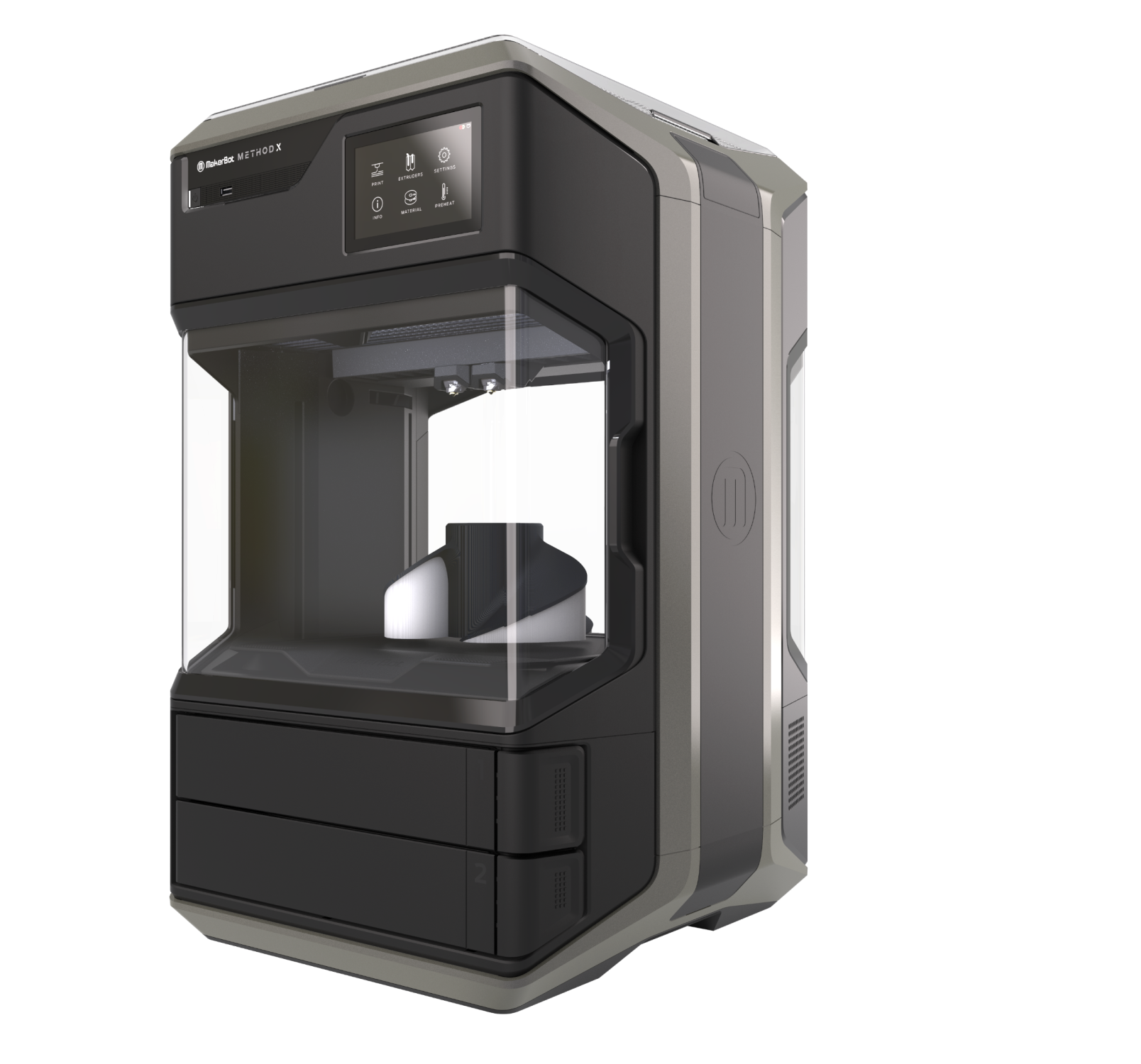

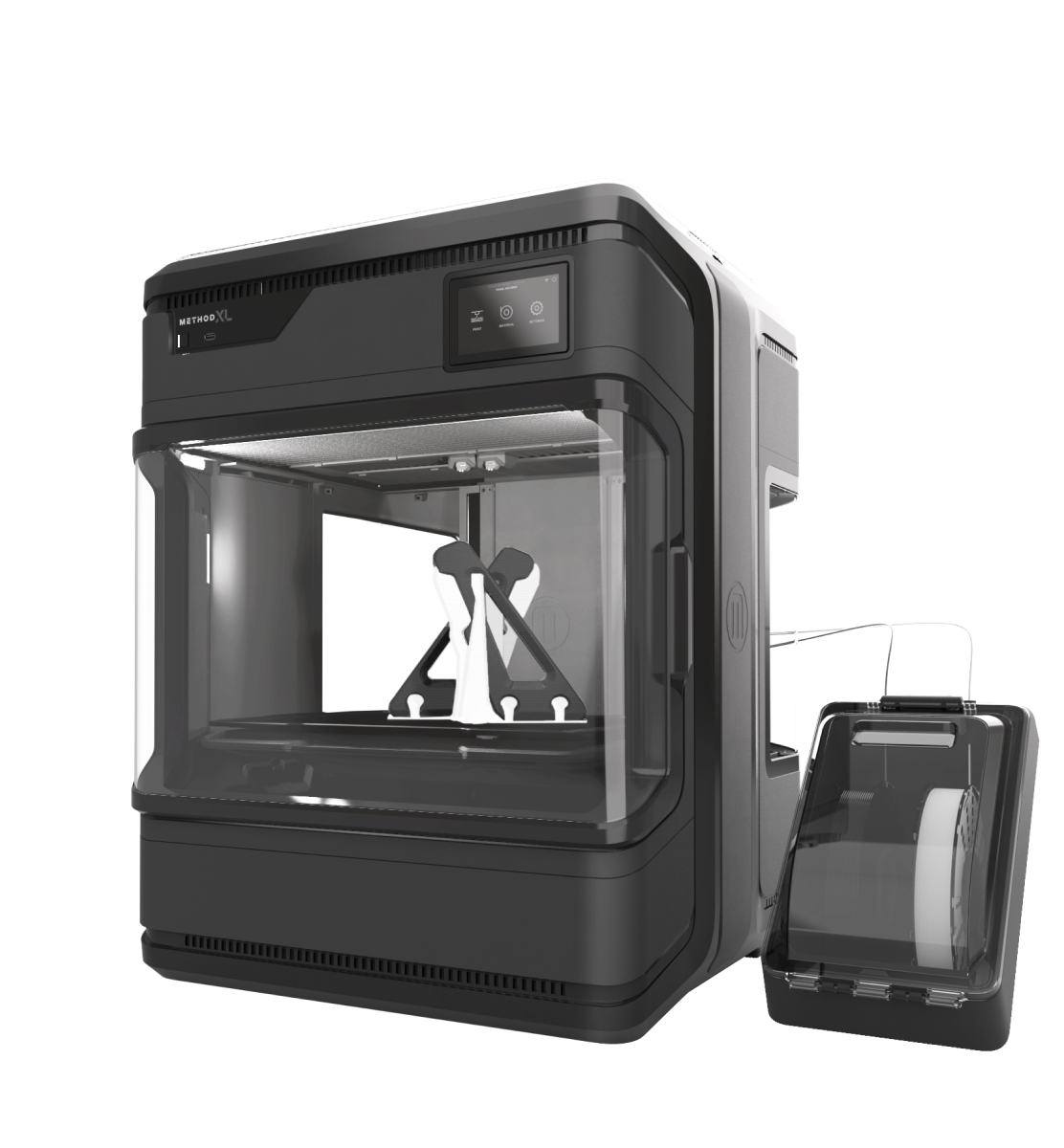

Actively heated chamber

Patented VECT™ 110 Thermal Regulation evenly heats and controls the print environment leading to parts that are 2x stronger on the z-axis, and 2x more accurate across the board. (Variable Environmental Controlled Temperature)

Actively heated chamber

Maximum temperature:

110° C

Thermal Regulation evenly heats and controls the print environment leading to parts that are 2x stronger on the z-axis, and 2x more accurate across the board.