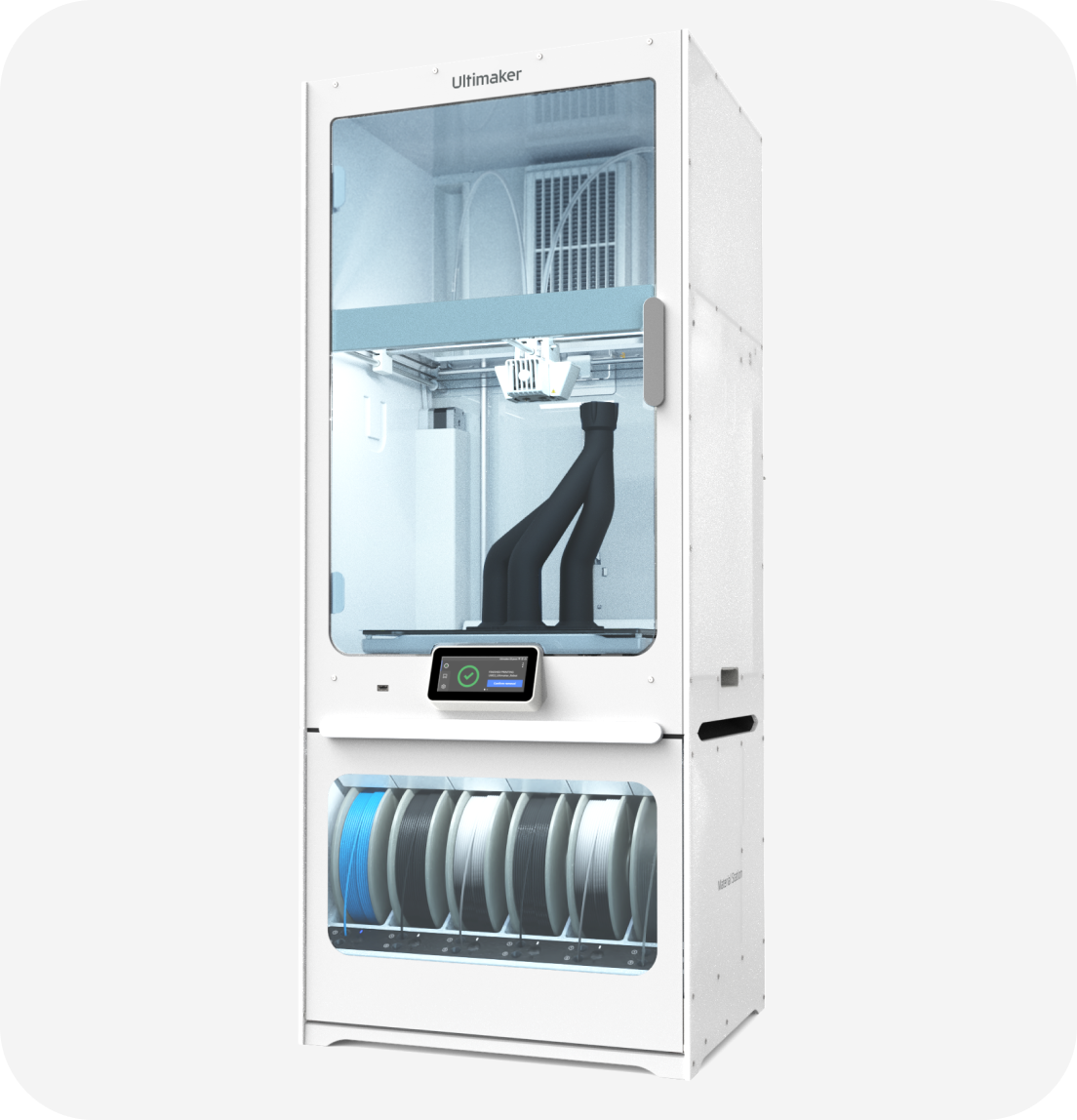

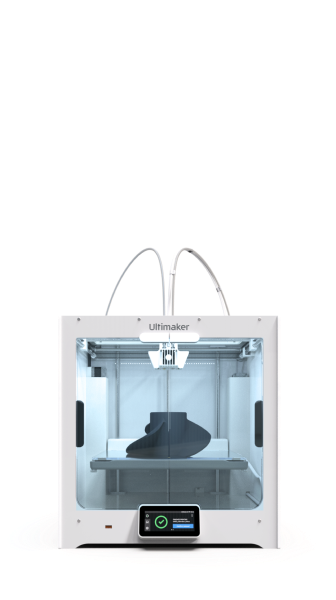

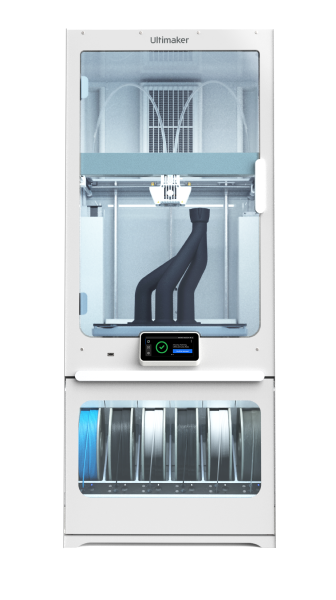

轻松呼吸。

集成空气管理器

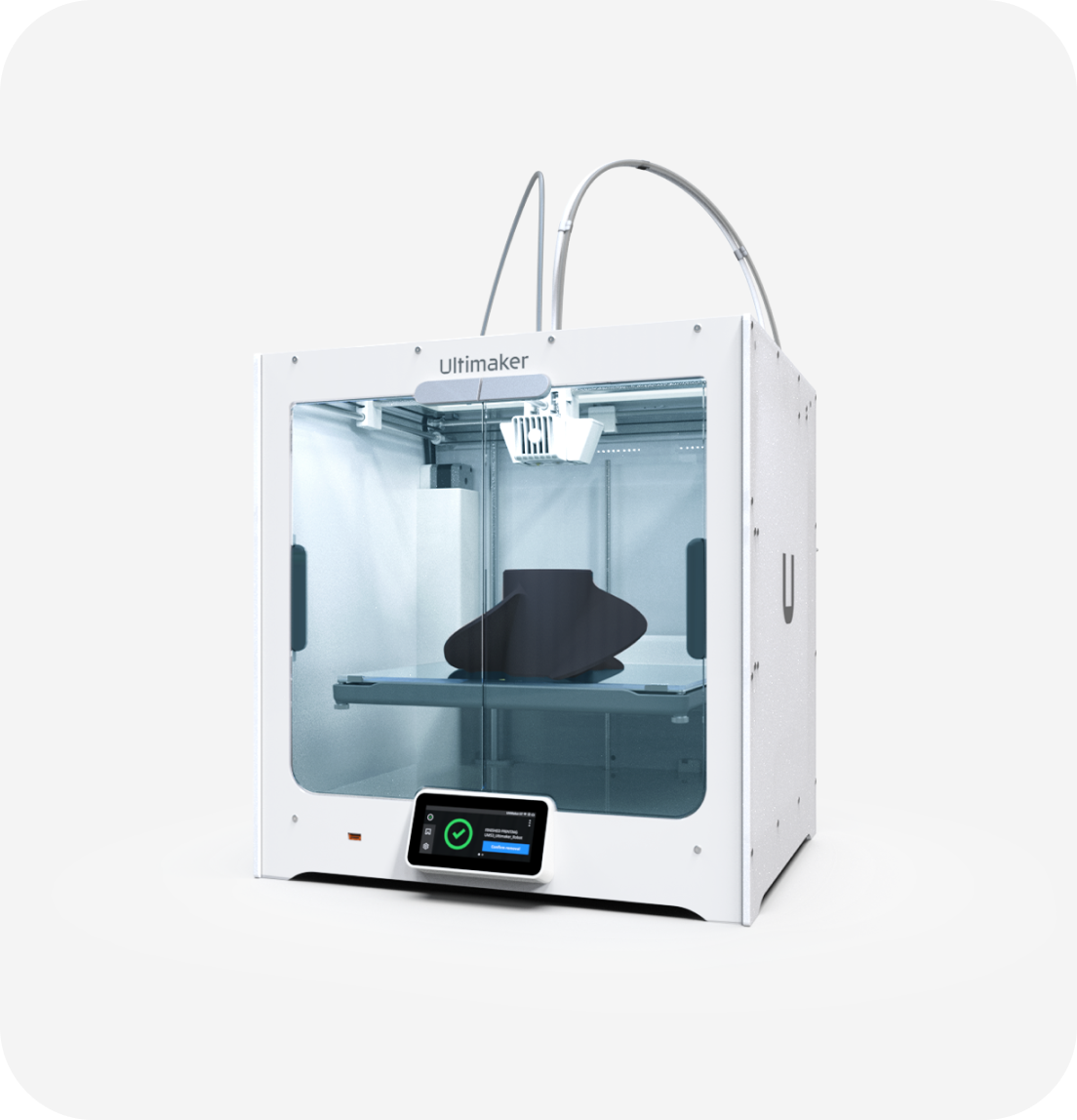

此举不仅增强了空气质量的安心感……它还由于其完全封闭的构建舱和单片玻璃门,提升了打印质量。

独立测试

从每次打印中去除高达95%的超细颗粒。*

* 经Fraunhofer WKI测试。仅包括UltiMaker材料。

主要特性

此举不仅增强了空气质量的安心感……它还由于其完全封闭的构建舱和单片玻璃门,提升了打印质量。

独立测试

从每次打印中去除高达95%的超细颗粒。*

* 经Fraunhofer WKI测试。仅包括UltiMaker材料。

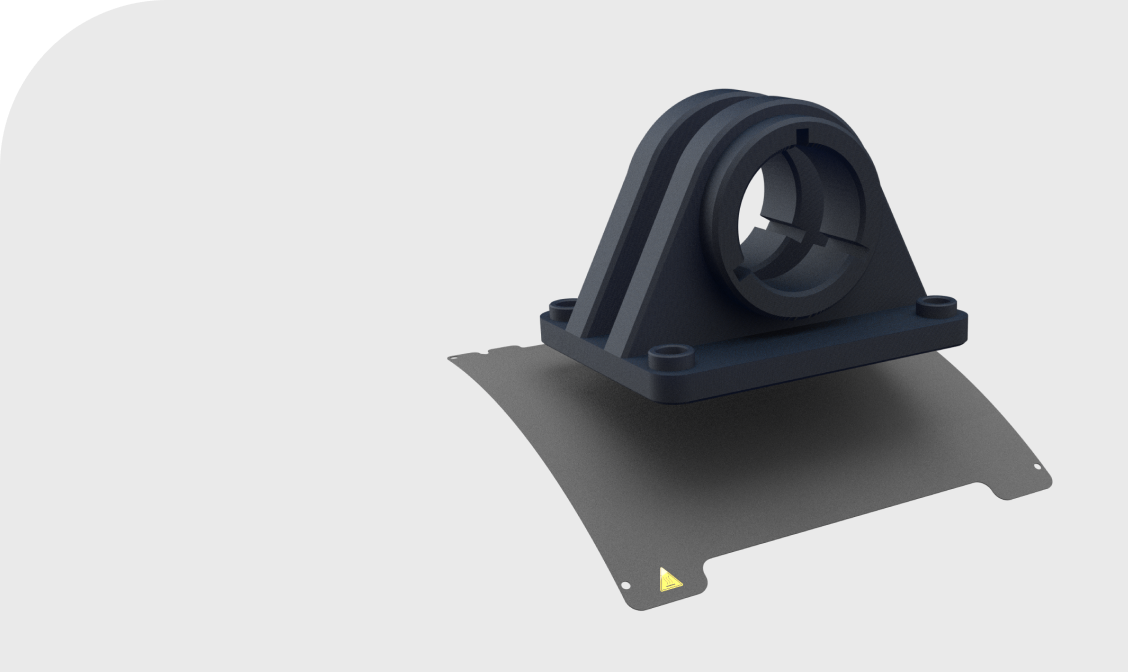

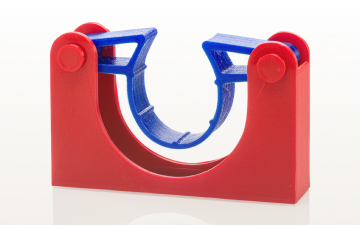

跳过使用胶水,使用PEI涂层的柔性构建板轻松拆卸部件。其待审专利设计使用了25个磁铁和4个销,以实现完美对齐——减少使用S7的时间,提高生产力。

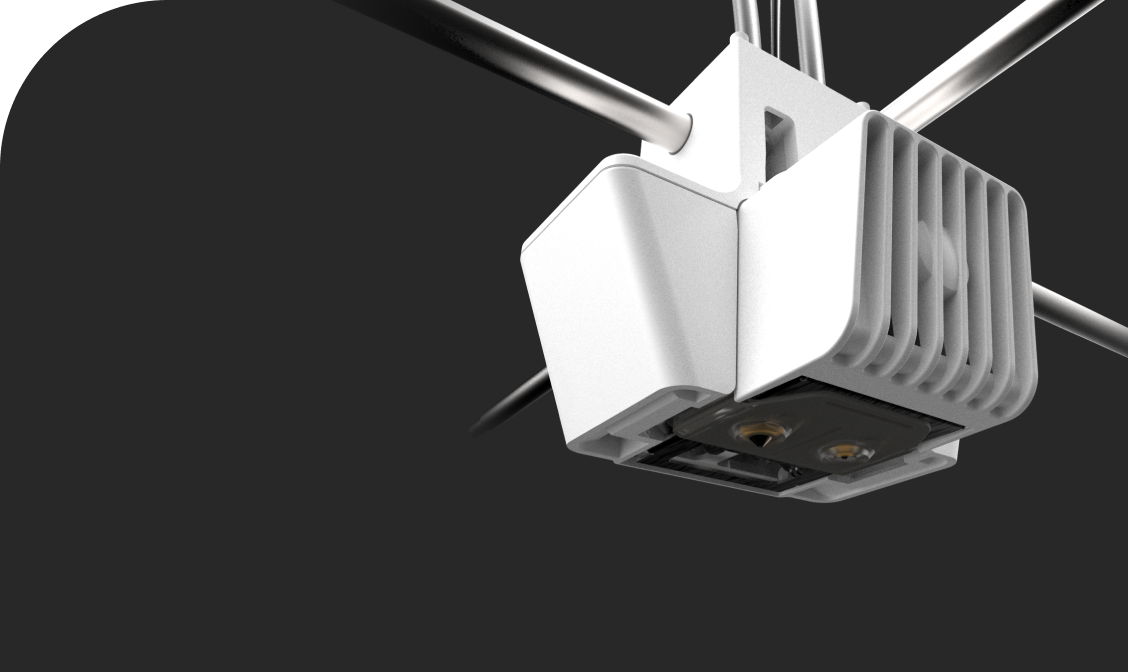

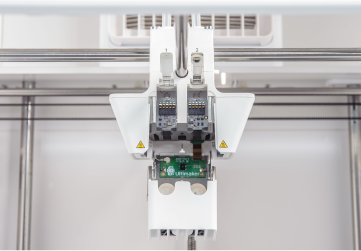

一种新型的感应式打印头传感器以更低的噪音和更高的精度探测构建平台。而自动倾斜补偿消除了对拇指螺丝床校准的需求。这些共同使您能够开始打印并且走开——对于完美的第一层充满信心。

感应式传感器信号比背景电噪声强100倍。

解锁无限潜力的3D打印应用程序。这些材料配置文件已经被制造商和现场用户测试了数千小时。

访问UltiMaker Cura的功能,这些功能可以加快您的工作流程并提高打印成功率 - 像意图配置文件、简便的远程打印等等。

如果您拥有 UltiMaker S5,您整个的 S5 打印文件数字图书馆将可以在 S7 上无缝工作——无需重新切片。

重新设计的打印头可以更早地检测到潜在的泛滥问题。它还包括更强的磁铁,以确保打印核心门保持关闭。重新设计的打印头可以更早地检测到潜在的泛滥问题。它还包括更强的磁铁,以确保打印核心门保持关闭。

Print Core

Hardness

Thermal resistance

Impact

strength

Print Core

Hardness

Thermal resistance

Impact

strength

Print core

Hardness

Thermal resistance

Impact

strength

Print Core

Hardness

Thermal resistance

Impact

strength

Print Core

Hardness

Thermal resistance

Impact

strength

Print Core

Hardness

Thermal resistance

Impact

strength

Print Core

Hardness

Thermal resistance

Impact

strength

Print Core

Hardness

Thermal resistance

Impact

strength

Print Core

Hardness

Thermal resistance

Impact

strength

Print Core

Hardness

Thermal resistance

Impact

strength

The physical space inside the UltiMaker S7 that can be used for single or dual extrusion 3D printing.

330 x 240 x 300 mm (13 x 9.4 x 11.8 inches)

The 3D printer's dimensions, including the spool holder.

W 495 x D 585 x H 800 mm (W 19.5 x D 23 x H 31.5 inches)

This is the process of depositing layers of filament, one on top of the other, to build up shapes and models. It is a form of additive manufacturing technology and the process used by all UltiMaker 3D printers.

熔融沉积成型 (FDM)

The filament diameter that achieves optimal results on UltiMaker S series 3D printers.

2.85 mm

The net weight of the 3D printer.

29.1 kg (64.2 lbs)

The peak power output that the printer can reach – usually when the heated bed and hot ends are heating up.

500 W

A micron is the measurement used to define the thickness of a 3D printed layer. 20 micron is 0.02 mm thick. Thinner layers are used for high-detail prints, thicker layers are great for fast prototypes.

0.25 mm nozzle: 150 - 60 micron 0.4 mm nozzle: 200 - 20 micron 0.6 mm nozzle: 300 - 20 micron 0.8 mm nozzle: 600 - 20 micron

The more accurate the stepper motors within the printer, the greater degree of accuracy and finer resolution can be achieved with each print.

6.9, 6.9, 2.5 micron

Enhanced feeders on the UltiMaker S7 move filament at a precise rate with an abrasive resistant feeder gear that's ready to print with composite materials. Flip the ergonomic locking lever to easily insert or remove your 3D printing materials.

双齿轮给料机,针对复合材料进行了加固

The award-winning touchscreen gives you intuitive control over your setup and shows a preview of your print. Supported languages: English, Dutch, French, German, Italian, Japanese, Korean, Portuguese, Russian, Spanish, Simplified Chinese.

4.7英寸(11.9厘米)彩色触摸屏

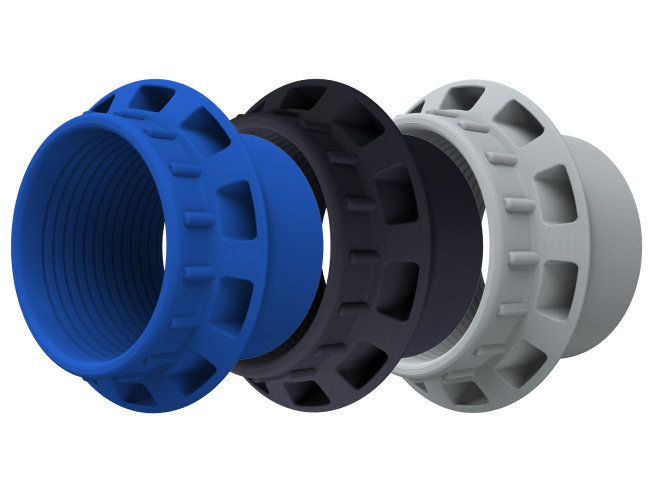

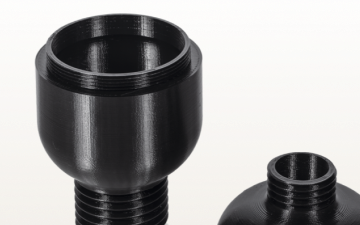

Faster print core changes mean higher uptime and easier maintenance. The UltiMaker S7 comes with print cores for build (AA) and water-soluble support (BB) materials. A print core for abrasive composite materials (CC) is available separately.

可更换打印核心

Thanks to swappable print cores, you can quickly switch between different filaments and material-matching print cores. This results in higher uptime and easier maintenance of your 3D printer.

双挤出打印头配备自动喷嘴升降系统、可更换打印核心以及泛滥检测功能。

Smaller nozzle diameters enable more detailed prints, large diameters reduce overall print time. This 3D printer ships with two AA 0.4 mm print cores and one BB 0.4 mm print core.

0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm

The printer will notify you when the filter needs replacing (every 1,500 print hours - about once per year).

可更换的EPA过滤器

The volume of air extracted per hour by the low-noise, brushless fan.

1 - 50 m³/h (35 m³/h nominal rate for most materials at 23 °C)

A wide nozzle temperature range means greater flexibility in the 3D printing material choice.

180 - 280 °C

The nozzle heat-up time relates to how fast you can start printing, as well as how fast it can melt the polymer filament.

小于2分钟

Thanks to their quiet operation, Ultimaker 3D printers are suitable for use in the office, studio, or classroom environment.

< 51 dBA

The redesigned print head of the UltiMaker S7 uses a more accurate inductive sensor to scan the build plate at multiple points. It then compensates for any Z-axis offset by adjusting the height of your print's first layers.

高级主动调平,采用更精确的感应传感器。

Simply bend the build plate and your 3D printed parts pop off. PEI coating allows for excellent adhesion without glue or support structures. 25 magnets and 4 pins ensure it can be replaced effortless with one hand.

PEI涂层的柔性钢制打印床

The build plate heat-up time relates to how fast it can reach the print-ready temperature.

< 5 minutes (from 20 to 60 °C)

This Ultimaker 3D printer operates best in locations between these temperatures.

15 - 32 °C (59 - 90 °F)

This Ultimaker 3D printer can be safely stored or left inactive at these temperatures.

0 - 32 °C (32 - 90 °F)

UltiMaker Cura is our industry-leading slicing software that turns your 3D model into a file your printer can use. Use UltiMaker Digital Factory to manage printers and print jobs via your local network or the cloud.

UltiMaker Cura – 打印准备软件 UltiMaker Digital Factory – 打印机管理软件 UltiMaker Essentials – 企业级在线软件工具

MacOS, Windows, and Linux

More plugins are available from Ultimaker Marketplace to make your 3D printing experience even easier.

SolidWorks, Siemens NX, Autodesk Inventor

An STL file is the most used file type for 3D printing. Nearly any 3D modeling software program is able to create these files.

UltiMaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG Printable formats: G, GCODE, GCODE.gz, UFP

Print with one click via Wi-Fi or Ethernet connection from UltiMaker Cura or UltiMaker Digital Factory. Or export your print job to a USB stick.

Wi-Fi (2.4 and 5 GHz), Ethernet, USB

CE, FCC, VPAT, RoHS, REACH, CB, BIS, KC, PSE, RCM, SRRC, MIC, NCC, Safe unattended professional use

了解更多关于UltiMaker S7安全性和合规性的信息。

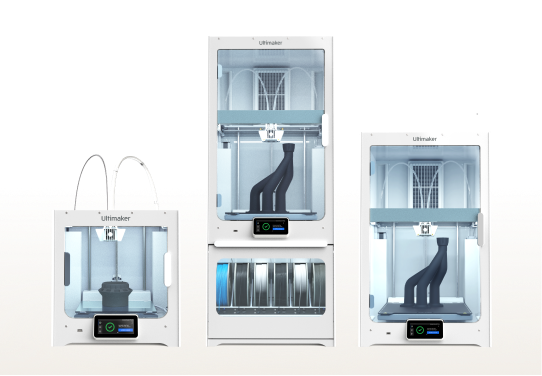

Perfect first layers with faster print removal and integrated air filtration.

请求报价 >

More space for bigger 3D prints with the widest choice of materials.

Request a quote >

The ultimate 3D printing workflow with automatic material handling.

请求报价Composite-ready dual extrusion that fits easily on your desk.

请求报价Build volume (XYZ)

Build chamber

Build plate

Extrusion

Print cores & nozzles

Compatible materials

Spool holder

Air filtration

Software

Build volume (XYZ)

Build chamber

Build plate

Extrusion

Print cores & nozzles

Compatible materials

Spool holder

Air filtration

Software

Build volume (XYZ)

Build chamber

Build plate

Extrusion

Print cores & nozzles

Compatible materials

Spool holder

Air filtration

Software

Build volume (XYZ)

Build chamber

Build plate

Extrusion

Print cores & nozzles

Compatible materials

Spool holder

Air filtration

Software