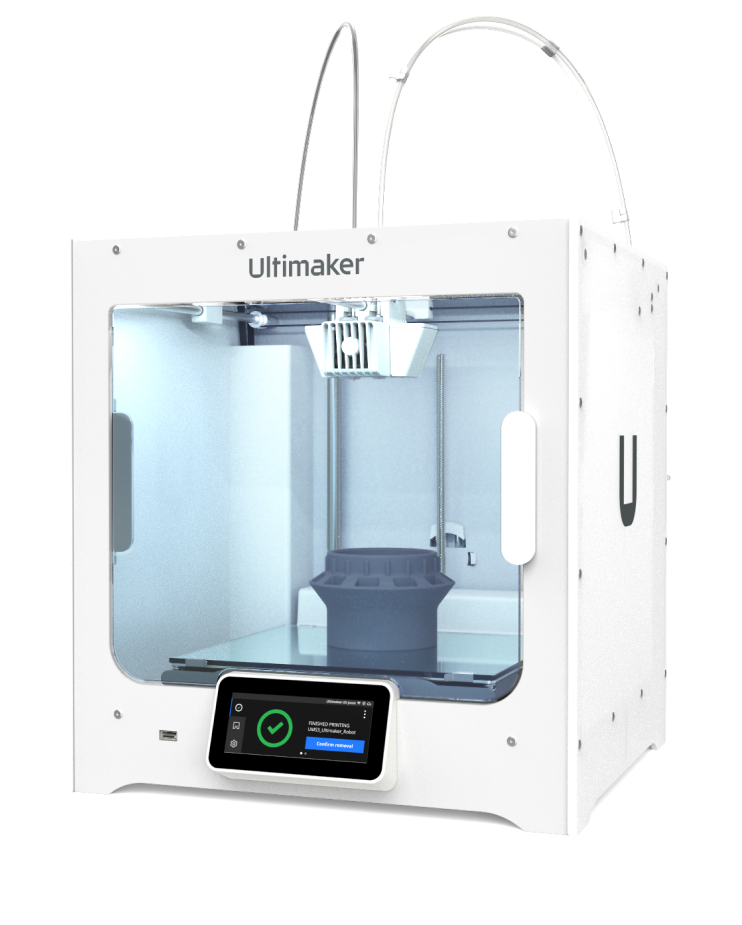

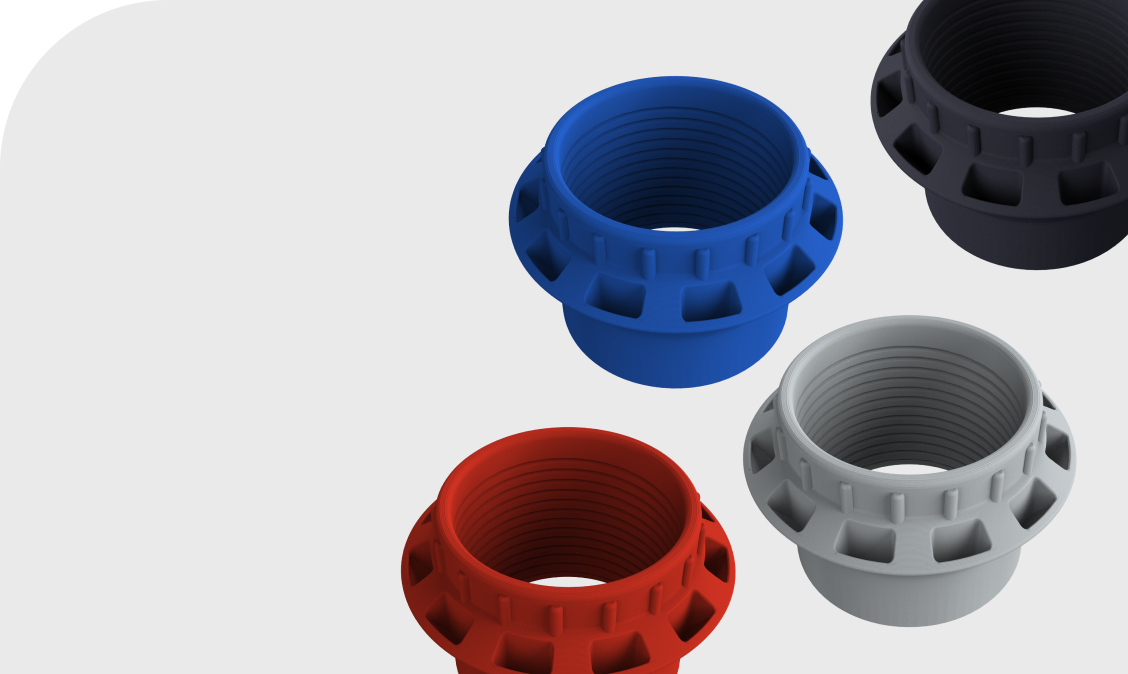

Click and print with 190+ materials

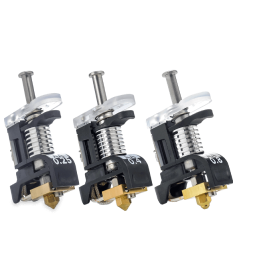

3D printing with the world's most advanced filaments is easy. Create strong parts using polymers reinforced with composite materials. Or combine the S3 with the Metal Expansion Kit to prototype functional stainless steel parts.

Compatible with

190+

materials