A failed print can mean hours of lost productivity, wasted material and delayed projects. This is especially critical in business or professional environments that rely on 3D printing where setbacks can prove costly especially when compounded over the service life of a 3D printer.

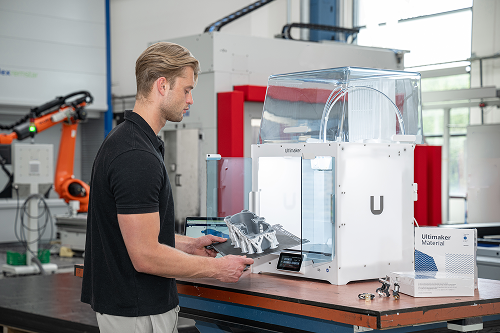

In this article we’ll break down the key factors that define what makes a 3D printer reliable, from durable hardware, design engineering, software security and ecosystem integration. Whether you’re scaling production or streamlining prototyping, here’s what to look for and how UltiMaker stands out.

What does reliability mean for 3D printers?

For 3D printers, reliability means consistent repeatable performance, the ability to deliver quality results with minimal downtime or intervention.

While there is a lot to be said on what impacts the lifespan of a 3D printer and how that ties into the reliability of the machine, we can distill the main factors that factor into the reliability of a printer into 5 main points:

Mechanical reliability

Referring to the physical robustness of the printer, its frame, motion components, extruders and material feeders, all of which must endure hours of operation without any degradation in quality. This includes precision and wear resistance over time.

UltiMaker has the background and history to prove its worth, the dual-material architecture has been proven since 2016 (when the UltiMaker 3 was launched) with the life expectancy of the various printer parts running high into thousands of hours.

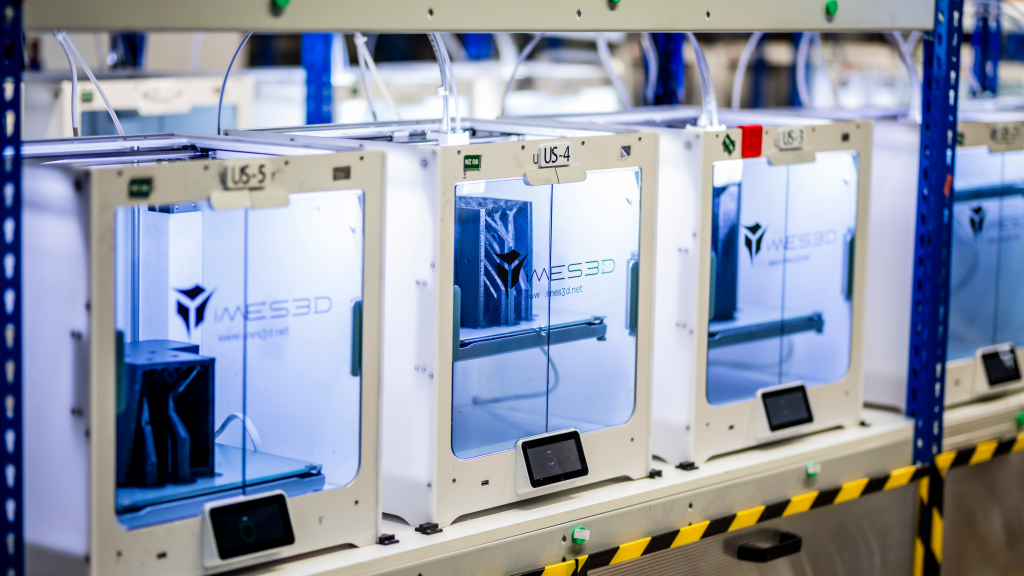

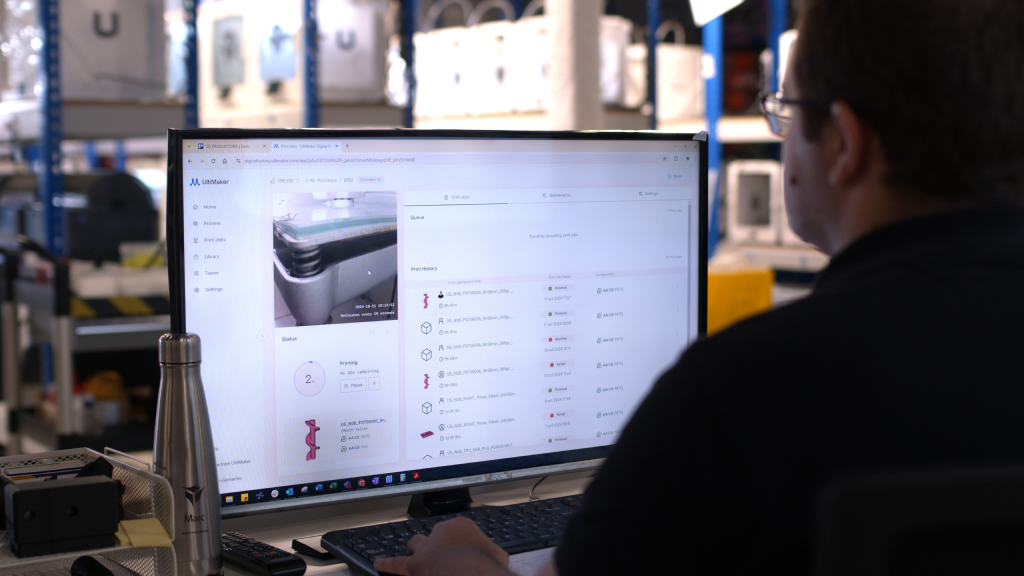

It’s not just rigorous testing and years of engineering expertise, our clients have validated the reliability of our machines time and time again, clients like IMES3D who provide expert support for industry level 3D printing.