3. Decide on printer and materials

Once your use cases are clear, select a 3D printer that aligns with your goals. Consider:

- Print volume: How large are the parts you need to make?

- Material compatibility: Do you require durable or heat-resistant materials?

- Ease of use and maintenance: Will the system integrate easily into your team's workflow?

- Security and safety: How important is the safety of intellectual property for your team? What about machine safety?

Materials play a key role in part performance. Depending on your application, you may need engineering-grade polymers, composites, or flexible filaments. The right combination of hardware and material unlocks reliable, repeatable results.

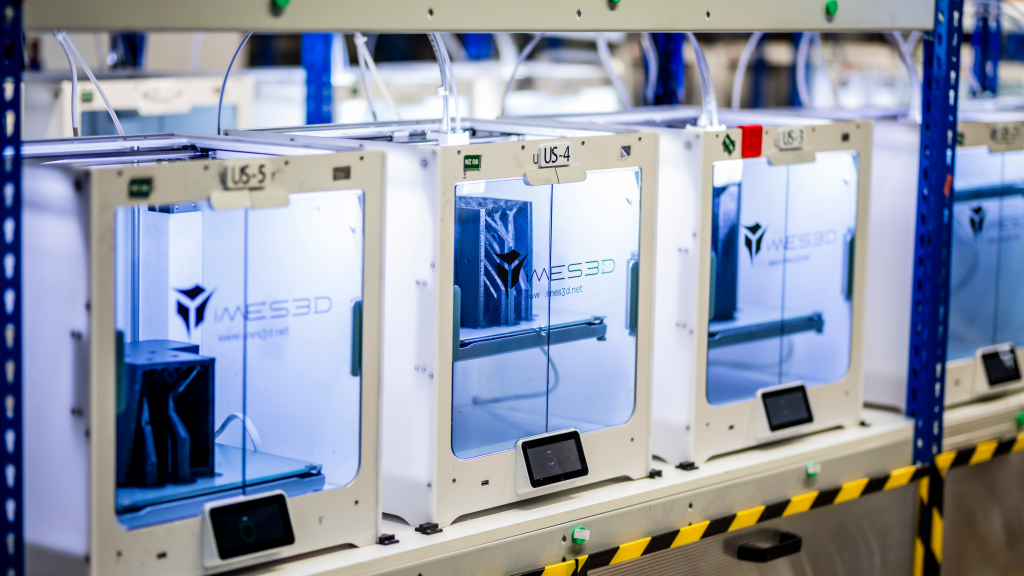

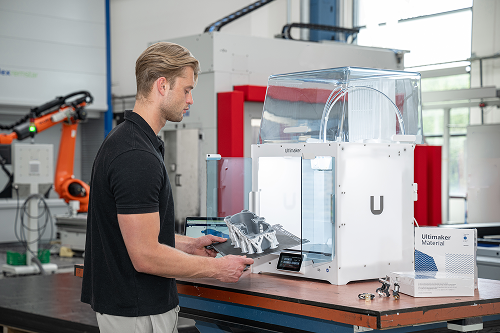

If you are looking for a reliable printer made in Europe, where quality meets speed, UltiMaker S6 might be suitable for your needs.

4. Design, print, and iterate

Additive manufacturing enables rapid iterations, so take advantage of it. Once you’ve selected your printer and material, start designing or importing 3D models for your chosen use cases. Many parts can be reverse-engineered or adapted from existing files.

Expect to go through a few iterations - this is part of the process. Test, gather feedback, and refine designs as needed to ensure parts perform as intended in real-world conditions.

Want to learn more about how 3D printing can be benefical in prototyping? Read our free guide on rapid prototyping

5. Educate and involve the team

To make additive manufacturing sustainable in the long term, share knowledge and build buy-in across departments. Offer training sessions for designers, engineers, and operators so they understand the benefits and basics of 3D printing.

Encourage experimentation and create a system for submitting ideas or requests. The more people see what’s possible with AM, the more use cases will emerge.

Looking to adopt 3D printing in your workflow? Get started with UltiMaker S6

Adopting 3D printing doesn’t have to be complicated. With UltiMaker S6, you get easy access to the whole UltiMaker ecosystem and fast prints without compromising quality. The new S6 comes with:

- UltiMaker Cheetah motion planner

- Improved bed leveling

- New dual-drive gripper-wheel feeders

- Optional flex plate

Backed by Cura Cloud, UltiMaker Digital Factory, and hundreds of validated materials, the S6 is a versatile, open option that delivers first-class productivity without compromising the rock-solid reliability your workflow demands.