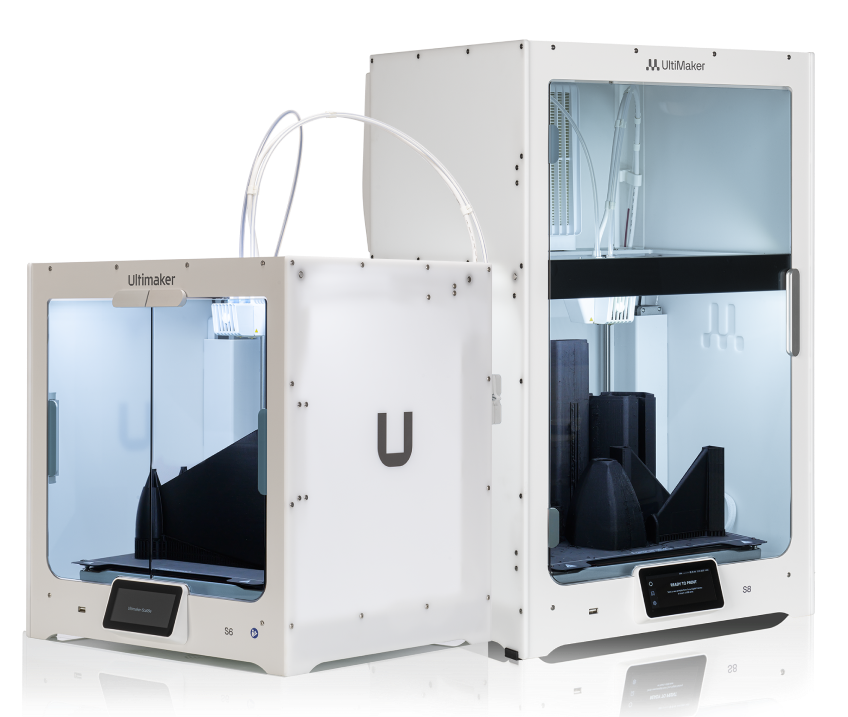

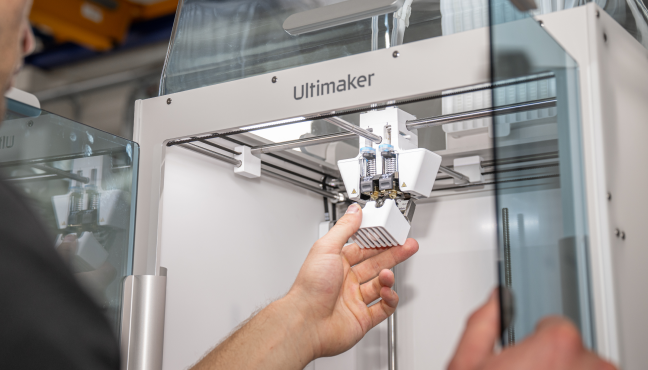

Defense-ready.

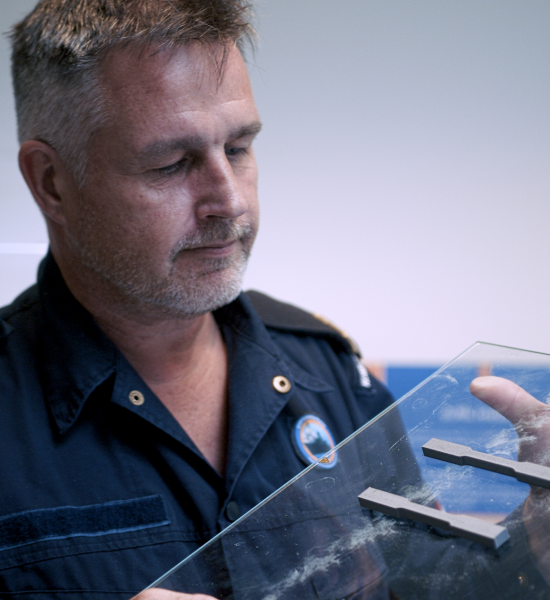

Security Without Compromise

Air-gapped operation with USB-only workflows. No Wi-Fi, no cameras, no unverified devices, eliminating vulnerabilities like espionage, data theft, or Trojan-horse printers.

Total Data Control

The system helps shield your intellectual property from espionage and data breaches.