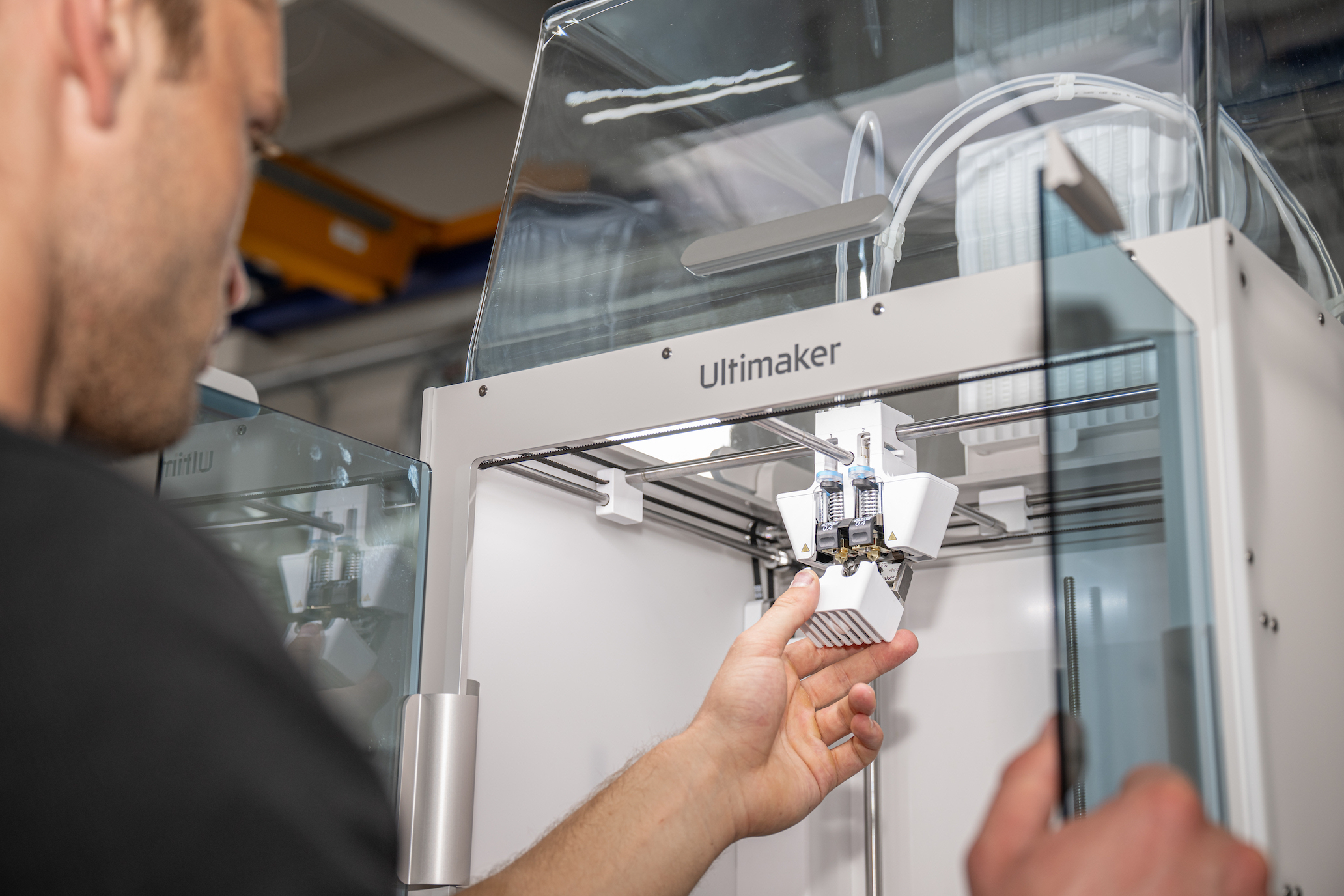

Hardware components

Let’s take a closer look at some of the hardware components that play a vital role in keeping a professional 3D printer running smoothly over years of use, and how UltiMaker printers are built for this purpose.

1. Power supply

For your professional 3D printer to work, you need power. Having a reliable and stable power supply will ensure that your device will run when you need it to.

UltiMaker uses Mean Well power supply for a consistent power delivery to prevent failures from power issues.

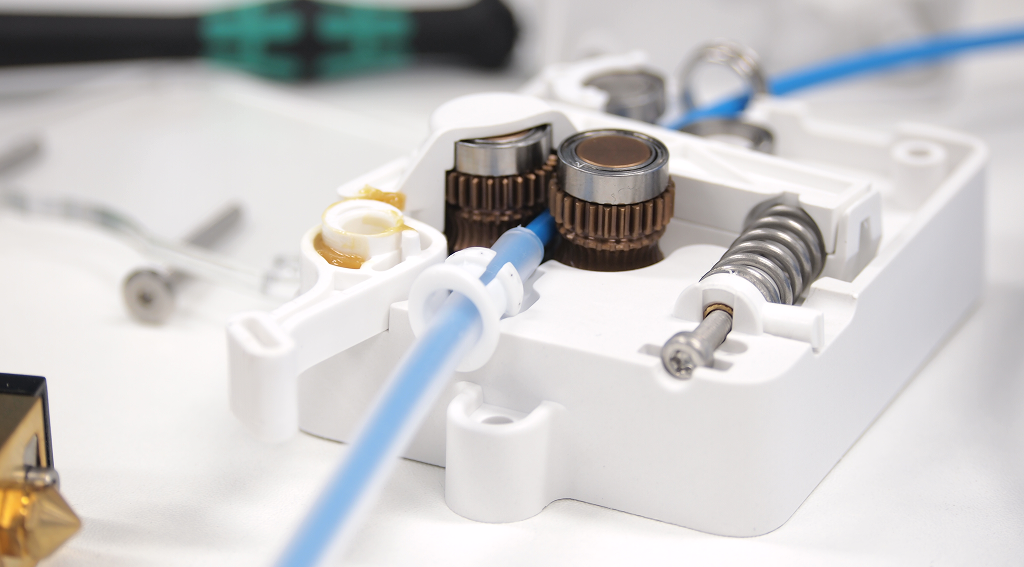

2. Motors

Having a quality motor provides precise control and reliability. UltiMaker S series is powered by MOONS motors, trusted for their accuracy, durability, and quiet operation, so you can achieve consistent print results with minimal downtime.

3. Bearings

Bearings are a small but important component. They allow motion components to move with as little resistance as possible. Thanks to the Cheetah motion planner, the forces on the motion system are as minimal as possible, which in turn reduces the wear and tear. Lower-quality bearings degrade quickly under continuous use, leading to increased friction, heat buildup, and wear.

UltiMaker printers are built with premium-grade bearings, selected specifically for their low-friction performance and long-term durability. This results in smoother motion, reduced maintenance, and a longer lifespan for your entire motion system.

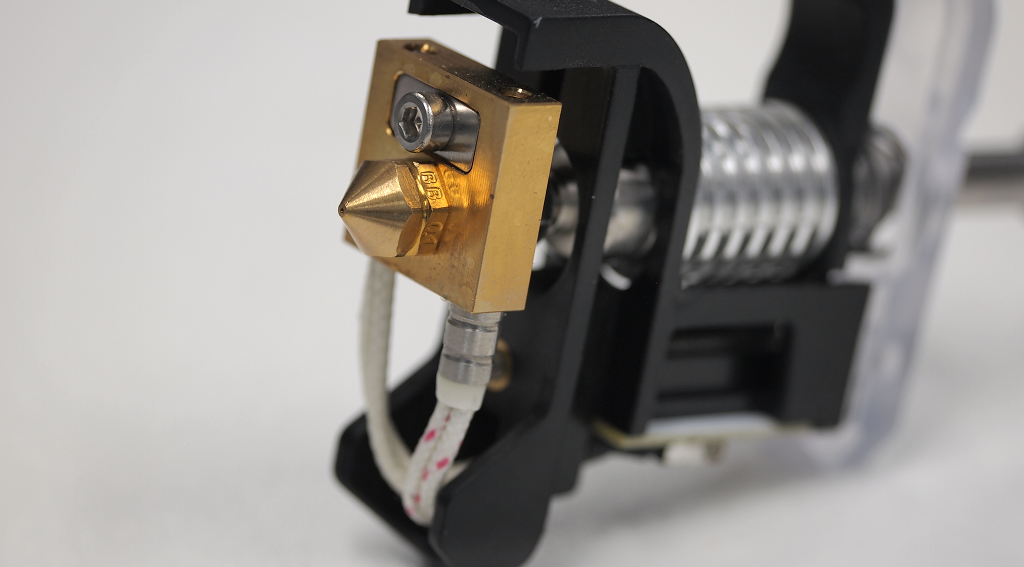

4. Print core

The print core is the heart of extrusion, and it takes a lot of wear over time - especially in lower-end systems where the material and build quality can’t stand up to long-term use. Worn-out nozzles or inconsistent heating elements lead to clogs, extrusion issues, and ultimately, failed prints.

At UltiMaker, we’ve tested our print cores far beyond their expected operational lifespan. The result is a system that delivers consistent, high-quality extrusion across countless prints, with the durability to match. Whether you're printing prototypes or production parts, our print cores are built to keep up.