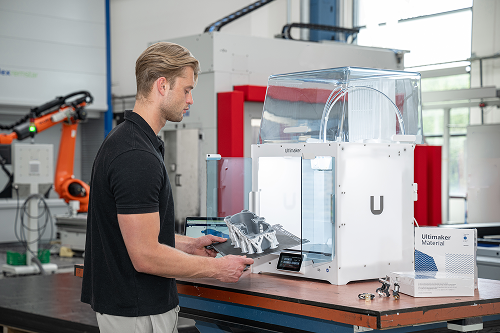

Welcome back to our application spotlight series, where we showcase how UltiMaker 3D printing technology delivers smart, cost-saving solutions across industries. From speeding up development to streamlining production, each application highlights how additive manufacturing keeps businesses moving forward.

This week, we’re looking at how the automotive industry used 3D printing to produce an air intake—faster, cheaper, and tailored for the job.

Driving performance with the right fit

Air intakes are essential in vehicle performance, channeling airflow efficiently into the engine. But designing and testing these parts requires prototypes that are both accurate and durable. Traditionally, producing them with conventional methods takes weeks and comes with a high price tag, slowing down development cycles.

Faster prototyping, functional results

By turning to UltiMaker 3D printing, engineers were able to create air intake prototypes in PLA for quick design validation. Once the geometry was finalized, functional versions were printed using PC - a material strong enough to withstand the demands of real-world use.

This dual-material approach gave the team both speed and performance, without the delays of outsourcing.

Efficiency gains at a glance

- Cost reduced from ~€200 to just €41

- Lead time cut from 2–3 weeks to only 24 hours

- Materials: PLA for rapid prototyping, PC for functional parts