The Ultimaker Cura 5.1 beta has arrived, and it builds upon the changes made in 5.0 to bring exciting improvements to owners of Ultimaker printers, like simplified metal FFF printing and increased surface quality. As well as brand new advancements like faster prints when using support materials as well as a streamlined slicing experience.

New metal FFF features enable metal printing

Alongside the launch of the Metal Expansion Kit, Ultimaker Cura 5.1 has enabled new metal printing capabilities. The following slicing features can be used alongside the Ultrafuse® 17-4 PH, Ultrafuse® 316L, and Ultrafuse® Support Layer* materials by BASF Forward AM:

DD print core support*. Support for the new DD 0.4 print core, a new print core made for handling the Ultrafuse® Support Layer material

Automatic shrinkage plate feature. When using a compatible Ultrafuse® metal material profile, a shrinkage plate will automatically be created that prevents your part from deforming during the debinding and sintering process

Automatic support interface feature. When using the Ultrafuse® Support Layer material, an interface layer will automatically be created between the object and the metal supports as well as between the model and the automatic shrinkage plate. This slicing strategy is specific for metal printing and ensures that the part will be well-supported and that the supports can be easily removed after sintering

*Currently only available in Europe. The Ultimaker Metal Expansion Kit is sold without the BASF Forward AM Ultrafuse® Support Layer and Ultimaker Print Core DD 0.4 at a lower MSRP in other territories (including North America)

A metal part printed with Ultrafuse® 17-4 PH. The print sits on a shrinkage plate and the Ultrafuse® Support Layer material is used to create a support interface layer between the print and the supports.

Along with these new features, metal printing is also aided by the following improvements to the Ultrafuse® 17-4 PH and Ultrafuse® 316L print profiles that were previously released in Ultimaker Cura version 5.0:

Automatic scaling. Your part is automatically scaled to compensate for shrinkage that takes place during the debinding and sintering process

Alternate wall directions. The direction of walls is alternated to prevent distortions during the debinding and sintering process

New slicing engine. The new slicing engine reduces internal gaps in your part that can lead to line delamination and cracks during debinding and sintering, as well as allowing for the printing of thinner walls and finer details than was previously possible when printing with metal materials

Combined, these allow for a complete metal FFF solution that’s more reliable and simpler than ever. Enabling affordable and effective printing of stainless steel parts.

If you want to find out more about these new features, as well as the Metal Expansion Kit, watch our recent metal FFF roundtable webinar. You can also watch our Ultimaker Academy course on metal FFF printing.

Better surface quality with increased segment resolution

In our never-ending quest to help you get the best-looking prints possible, we have massively increased the segment resolution of your prints when using Ultimaker S-line printers with the latest firmware. This means that when printing models with smooth curves like spheres, cones, and cylinders. As well as more complex models made up of many organic shapes, up to twice as many individual segments will be printed. The result is noticeably improved surface quality. This was achieved by implementing a new resolution algorithm, as well as the removal of unnecessary jerk and acceleration from travel commands within gcode. The removal of these redundant commands resulted in reduced printer vibrations, as well as gcode files that are up to 20% smaller.

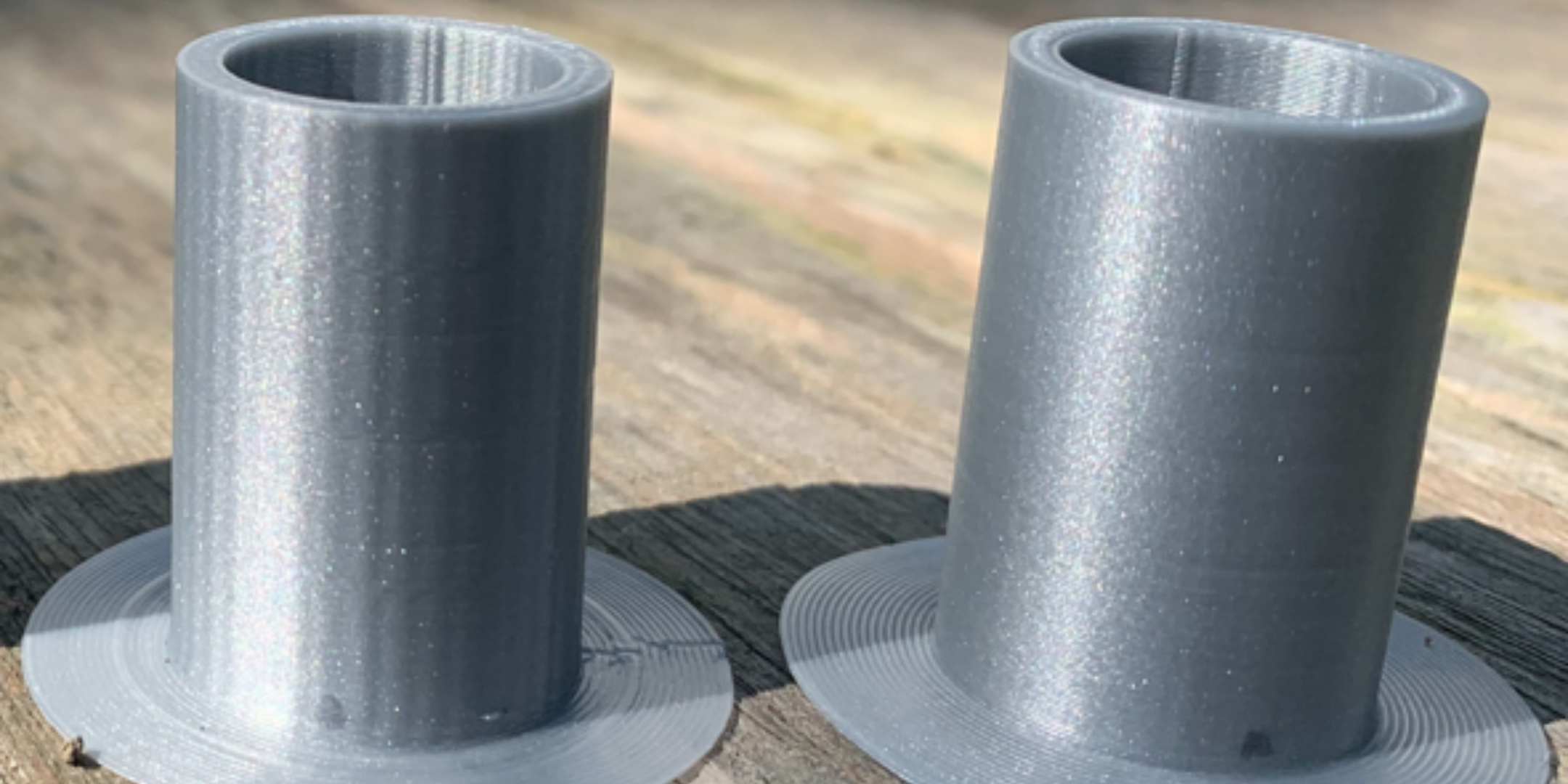

Left: printed using Ultimaker Cura 4.13 and old firmware. Right: Printed using Ultimaker Cura 5.1 and new firmware.

When judging surface quality improvements, the biggest differences can be seen when comparing against Ultimaker Cura 4.13. This is because the foundation of these improvements was made in both Ultimaker Cura 5.0 and S-line firmware version 7.0.3, with print profile tweaks and changes that were made to reduce buffer underrun, respectively.

Note: This feature requires you to be using firmware version 7.0.3 or above on your Ultimaker printer. Download the latest firmware version to make sure your printer is fully compatible.

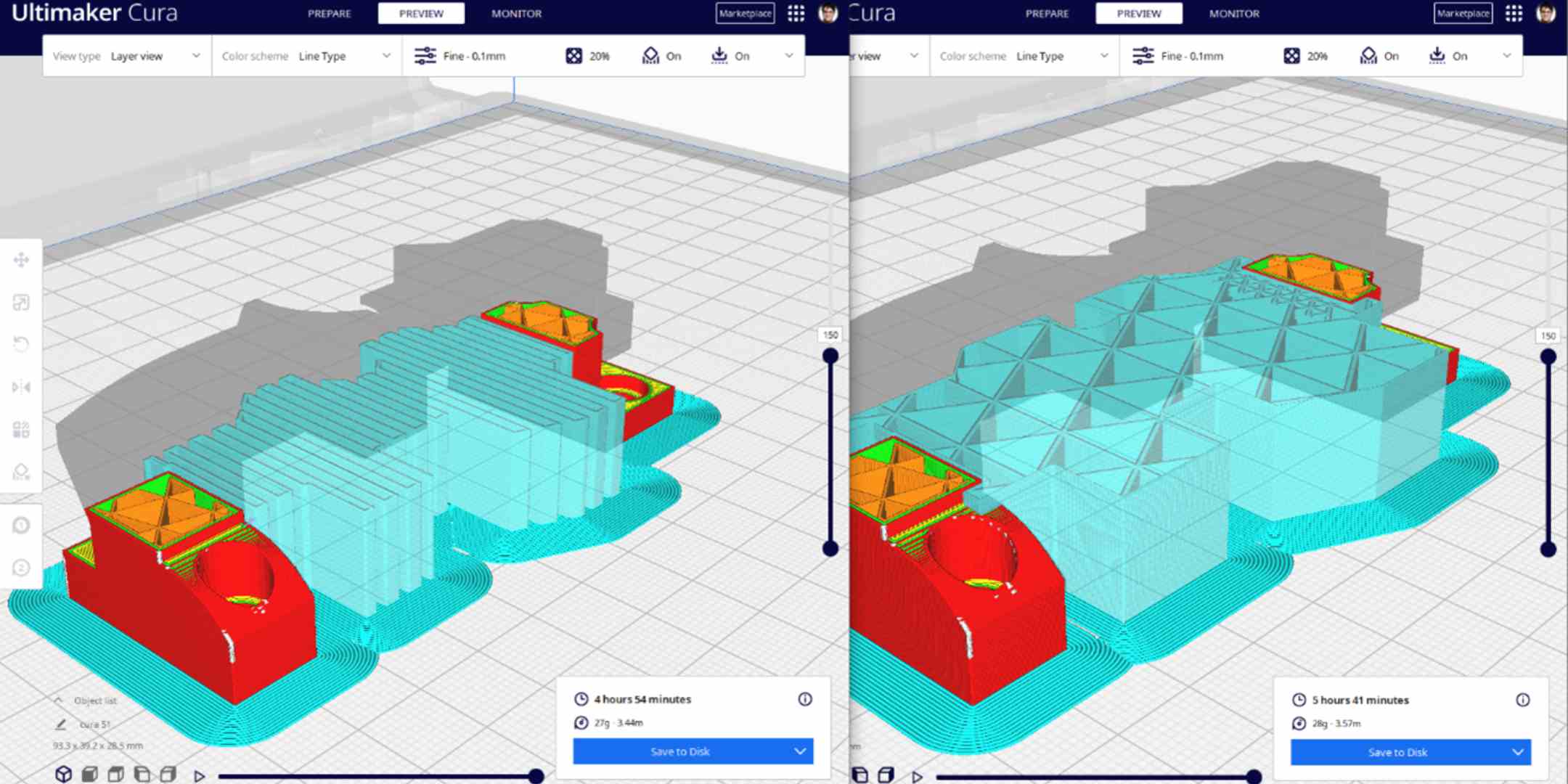

Faster printing when using support materials

We have improved both the speed and quality of supports printed with the Ultimaker PVA and Ultimaker Breakaway support materials. Resulting in faster prints, more reliable support structures, and improved surface quality on the part of your print that is being supported. Support structures printed with the Ultimaker PVA support material will also dissolve more quickly, reducing the time it takes to remove supports after printing. Especially when using the Ultimaker PVA Removal Station. Print times when using these new support structures can be as much as 20% faster.

These improvements have come from a variety of tweaks but the most significant are that when printing with these profiles, supports will now be printed using a zig-zag pattern instead of the previous triangle pattern. The outer wall around the supports has also been removed and the density of supports has been increased.

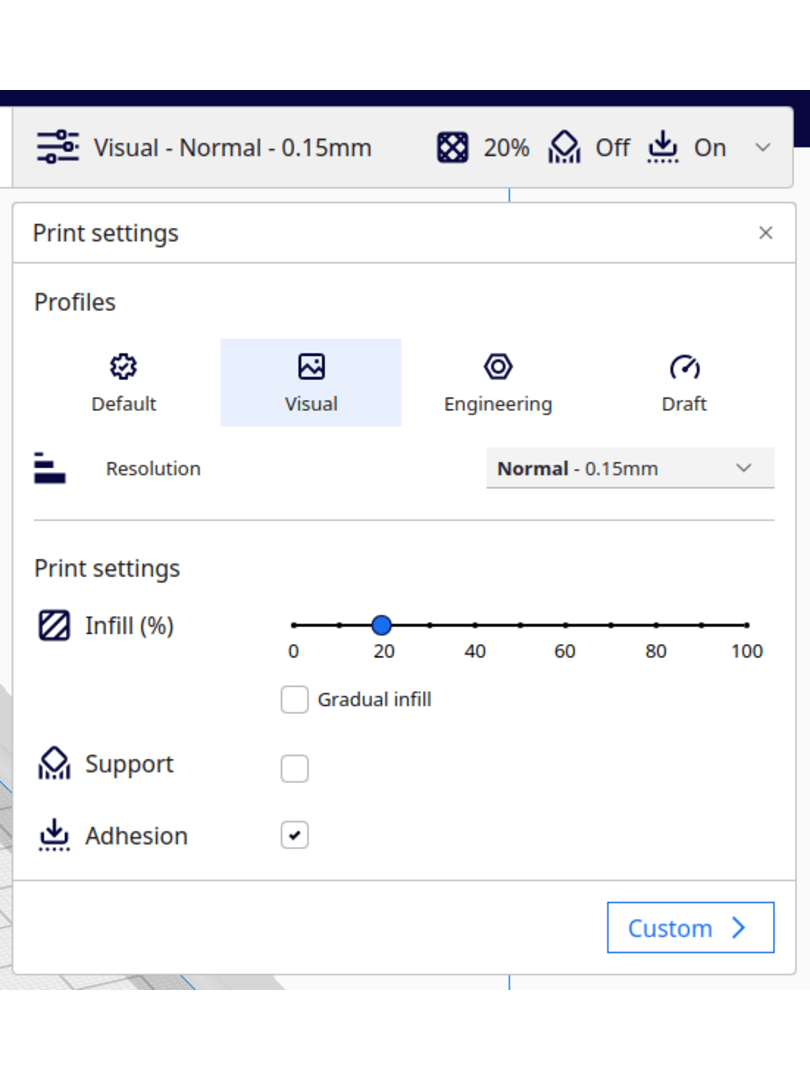

Streamlined slicing process

Following extensive user testing, we have modified the slicing process for materials that use intent profiles to make it as intuitive and straightforward as possible. We have now separated out the decision of which intent profile and layer height you want to use into two separate and easy-to-understand choices. In addition, a tooltip has been added that will notify you when settings have been adjusted. The settings which have been adjusted can then be identified by going to custom mode where they will be in italics and accompanied by an arrow symbol which will revert any changes when clicked.

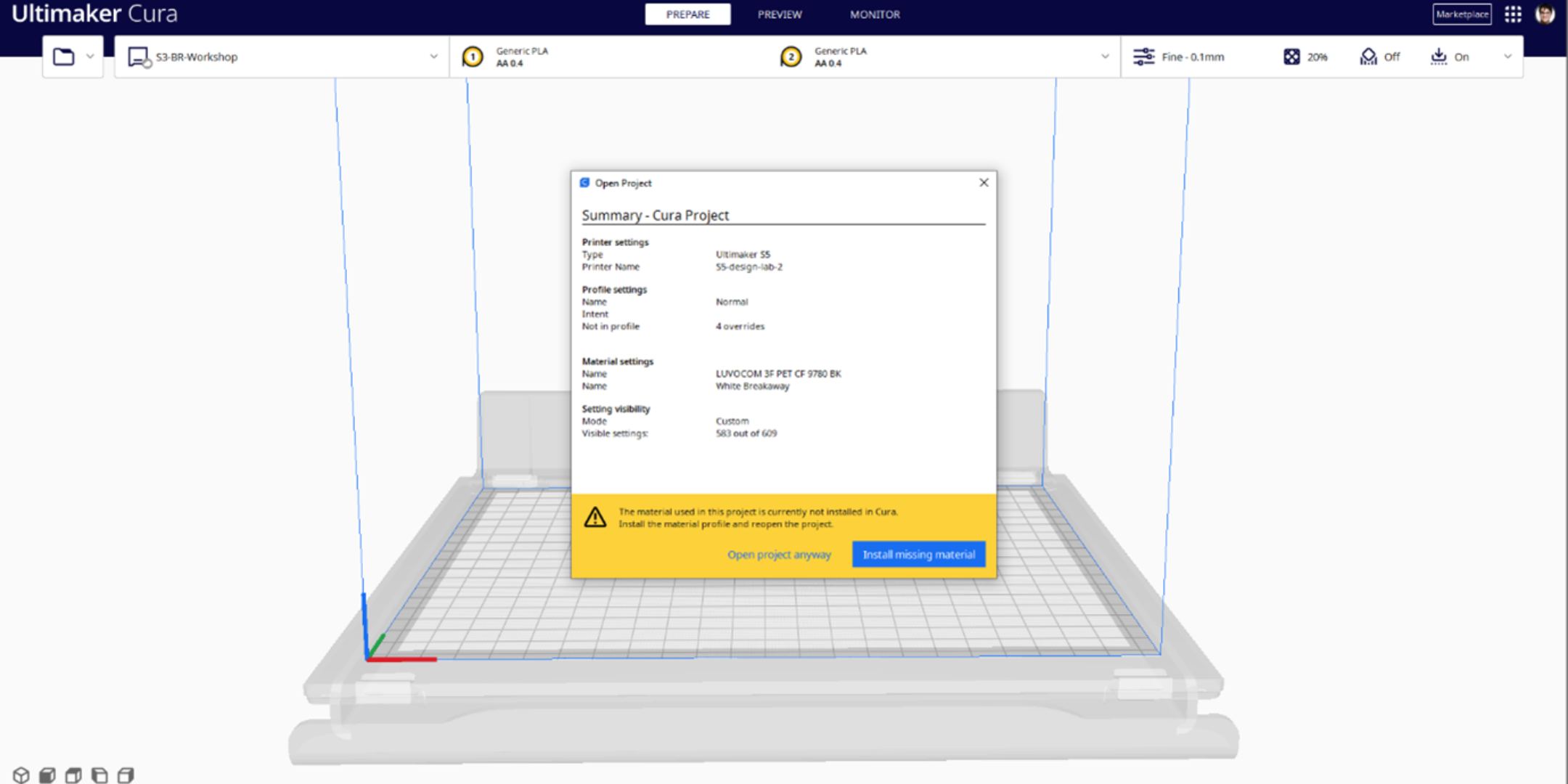

Downloading material profiles is now easier when using 3MF project files

It’s now easier than ever for you to collaborate with other users while using any of 250+ materials available in the Ultimaker Marketplace. When loading up a 3MF project file that uses a material profile that you do not currently have installed, you will be prompted to download and install any missing profiles.

Additional improvements

The following improvements have also been implemented in the Ultimaker Cura 5.1 beta:

Material profiles for new upcoming Tough PLA colors (blue, yellow, and gray)

Numerous bugfixes including security fixes and an issue with monotonic ordering that prevented it applying to the topmost surface layer of prints. A full list of bugfixes can be found here

Give us your feedback

Try out the exciting features mentioned in this article right now by downloading the beta. And please, share your feedback with us and the rest of the Ultimaker community!