In high-performance industrial environments where mechanical components are exposed to continuous friction and repetitive motion—such as packaging lines, conveyor systems, and various machines used in automated production processes—materials like POM (Polyoxymethylene) have long been favored for their low friction and high wear resistance.

However, as operational demands evolve and environmental regulations place greater emphasis on material safety and sustainability, traditional materials like POM are increasingly challenged by limitations in process flexibility, waste generation, and chemical composition.

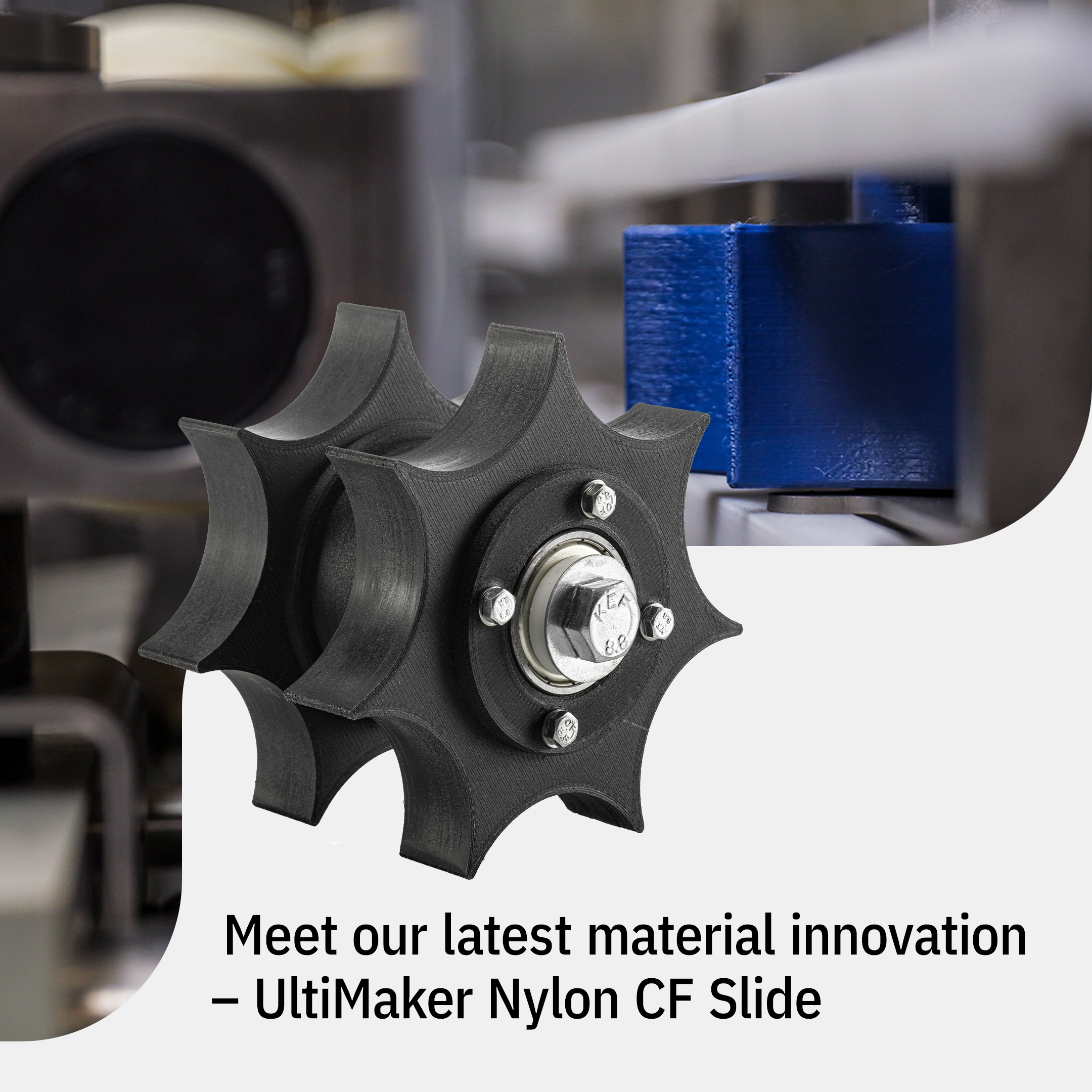

In this guide, we’ll explore how UltiMaker Nylon CF Slide, a carbon fiber Nylon filament developed for 3D printing, offers an excellent alternative to POM.

What is POM? A widely used engineering plastic

Before we dive into Nylon CF Slide, it’s important to understand what POM is and why it’s widely used in various industrial applications.

Polyoxymethylene (POM), also known as acetal, Delrin® (DuPont), or polyacetal, is a high-performance engineering thermoplastic used extensively in applications that demand low friction, excellent wear resistance, mechanical strength, and high dimensional stability over time.

Thanks to these properties, POM is commonly found in:

- Gears, bushings, and cams

- Conveyor belt components

- Bearings, rollers, and sliders

For full list, download our guide