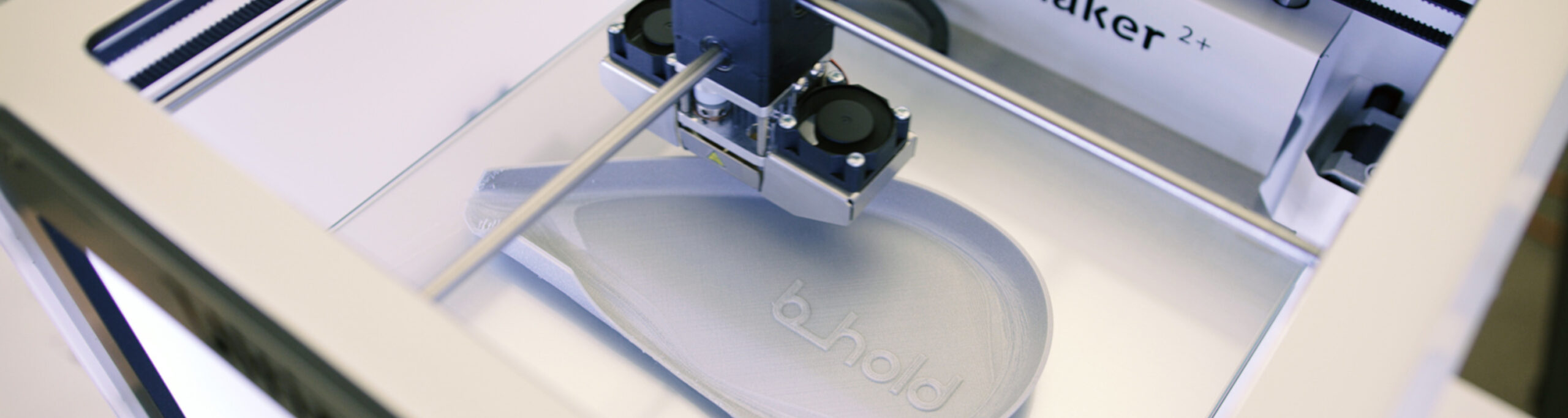

Passionate about tech and creativity, Susan has always wanted to build innovative products that were both practical and appealing. She started experimenting with 3D printing and modelling just as a hobby at first, and quickly realized that it was an efficient way to design and respond to people’s needs. In 2013, Susan founded Bhold, a design house that uses her Ultimaker 2+ to create smart, minimalist accessories, all rapidly prototyped and tested by real users worldwide.

3D-powered prototyping by the Bhold Studio

How far can you get with a dream and a 3D printer? Susan Taing, a product designer from New York proves that almost nothing is impossible. You can think of the most sophisticated forms and textures, turn them into successful products and blaze through prototyping and production at lightning speed.

Better, faster, smoother, smarter

3D printing, with all of its progress today, is the breakthrough technology that makes the design process much easier.

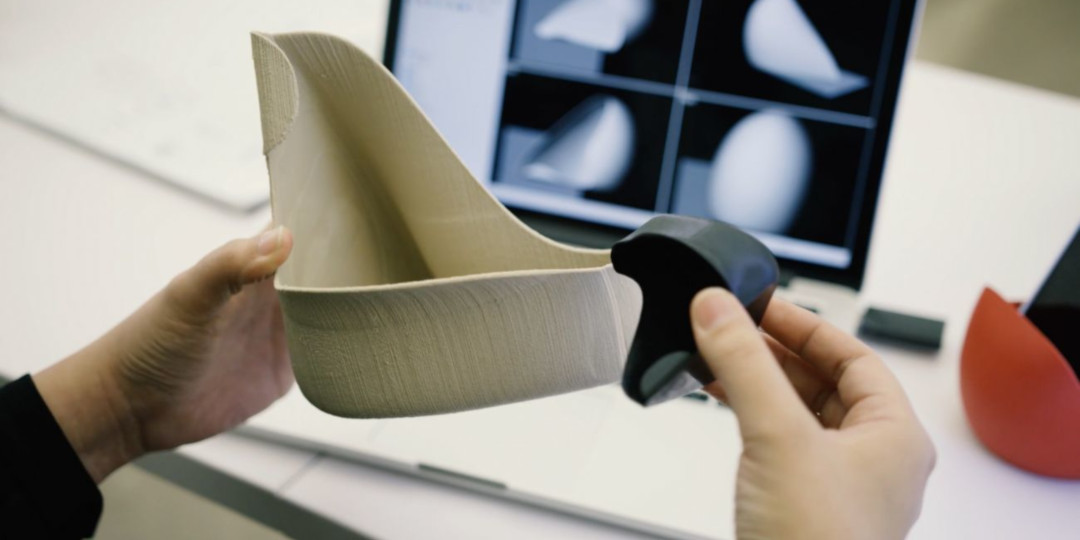

Unlike traditional product designers, Susan has a powerful advantage - a special group of beta testers providing fast, unbiased feedback. The Bhold Labs started off in New York and went global through the enormous Ultimaker community and YouMagine sharing platform. Now anyone can download 3D design files for many of Bhold’s products, print them, play around with them and share their experience. As a result, each concept might go through up to 100 revisions and tweaks, until it is 100% user-friendly, elegant, and functional.

Susan admits that with today’s level of 3D printing technology, product designers can explore as many versions as they need without the risk of hitting the market too soon. And while her Ultimaker 2+ is busy bringing her vision to life, she can focus on what she enjoys the most - designing and innovating.

When I first launched Bhold, if I had gone the traditional route I would have needed over a year for just one product, but with 3D printing I was able to launch with not one but four ready-for-market, thoroughly tested products in just three months.

Prototyping costs with 3D printing are much lower, because there’s no heavy machinery or tooling equipment involved. All you need is a reliable 3D printer, quality filament, and you're good to go.

Besides being faster and more cost-efficient, 3D printing also opened up a whole new world of complex and beautiful geometries that were simply impossible to achieve with traditional alternatives.

Today, Susan is excited to bring a brand new product to the market - the Bsonic iPad Speaker, 3D printed and prototyped on Ultimaker.

It's been amazing to have 3D printing enable my work. I'm fairly certain this technology will make the world a better place, and I'm so excited to be a part of it.

Make sure to check out the Bhold website and see all their handy, minimalist accessories for yourself. And of course, don’t hesitate to drop a line in the comments below if you have any questions or story suggestions. We love hearing from you!