PVA support material is used for 3D printing objects with complex geometries, cavities, or overhangs. PVA supports a model’s shape while it is 3D printed, then dissolves away in water. But as its chemistry makes it sensitive to moisture, its quality can reduce over time in storage. We look at some of the ways you can store and care for your PVA material to get the best results.

Ultimaker PVA material is formulated to be less moisture-sensitive than other PVA filaments, but it still helps to look after it in the right way.

How to store PVA spools

Storing your PVA in optimal conditions is key to a high-quality 3D print. If stored improperly, PVA can absorb ambient moisture (you will notice it becomes soft, pliable, and maybe even sticky) or become too dry (making it brittle), both potentially causing extrusion problems and loss of print quality.

If moisture is the problem, you may see bubbles in your PVA filament caused by the moisture and notice a popping sound when printing. Print quality will be reduced, with bad layers of PVA support likely to cause failed prints. This could also lead to your BB print core becoming clogged (read more about how to fix a clogged print core).

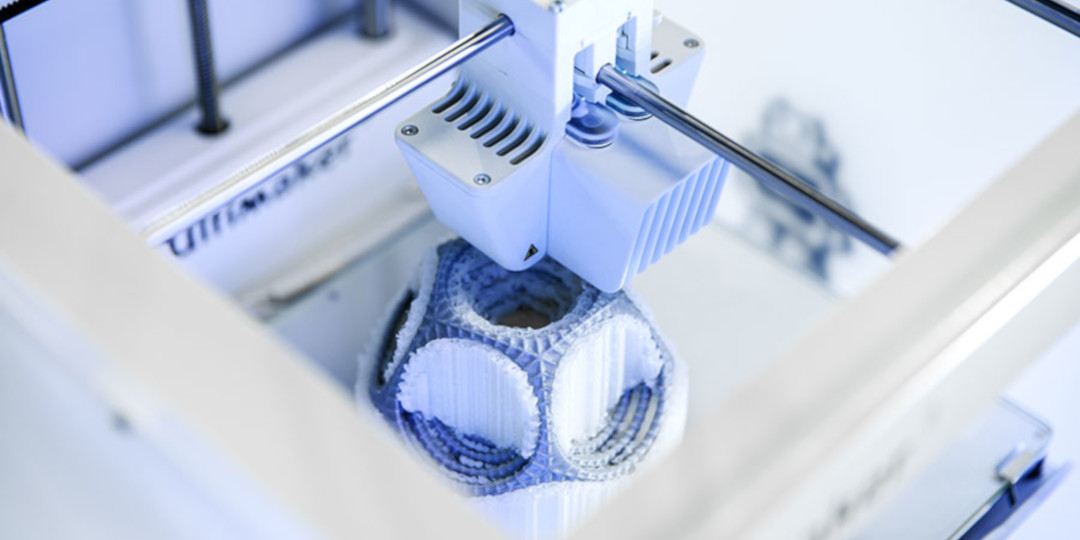

PVA printing correctly. If PVA is damaged, it will appear discolored and print with poor layer adhesion

One of the best ways to avoid any problems is to keep your PVA in a sealed container when you are not using it. If you have Ultimaker PVA, we recommend reusing the resealable bag and desiccant included in the original packaging as a starting point. This should be enough to keep your material in good condition.

If you use PVA frequently with the Ultimaker S5, the Material Station accessory offers a unique solution for storing materials in optimal conditions. Its six-spool capacity chamber controls the environment to keep relative humidity below 40% at all times. So there's no need for DIY dry boxes as well as less time spent operating the printer.

Ultimaker S5 Material Station loaded with PVA and other materials

Some third-party manufacturers provide other solutions, such as specialist filament storage boxes, or you can use another type of air-tight container you may have to hand.

The optimal temperature for storing PVA is between 0 °C and 30 °C, and recommended relative humidity for your storage area is below 50%. We also recommend you keep it out of sunlight.

What if your PVA loses quality?

If your PVA does absorb moisture, it is still possible to dry it out again.

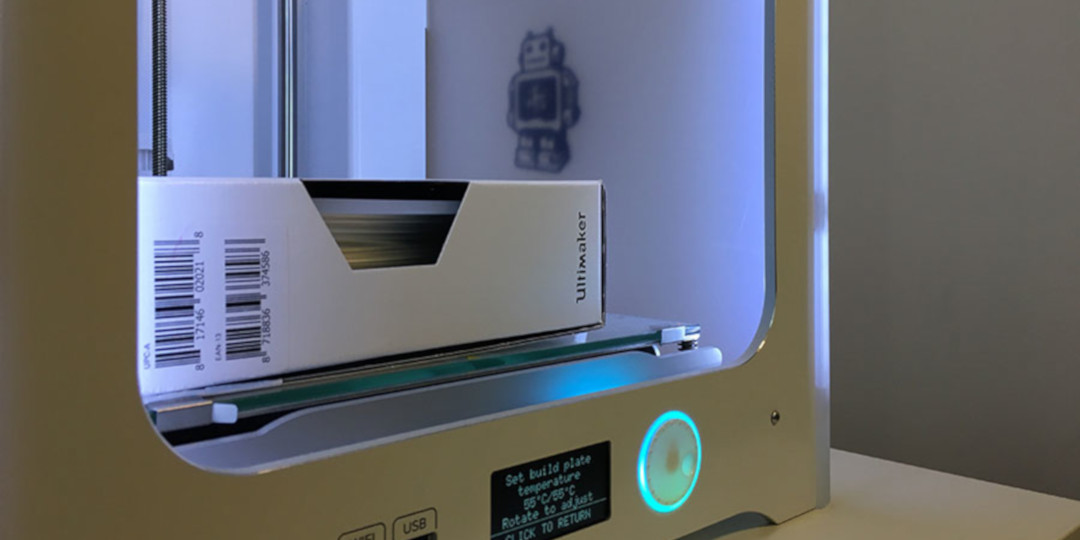

PVA filament drying on the Ultimaker 3 build plate

The easiest way to dry the filament is with your Ultimaker 3D printer’s heated build plate. Place the spool inside a cardboard box (for example an Ultimaker filament box) and on the build plate, heat it up to 55 °C, and wait for a few hours while the filament dries.

But, as the saying goes, prevention is better than a cure.

The Ultimaker S5 Material Station is available as an accessory from your local reseller, or as part of the Ultimaker S5 Pro Bundle.