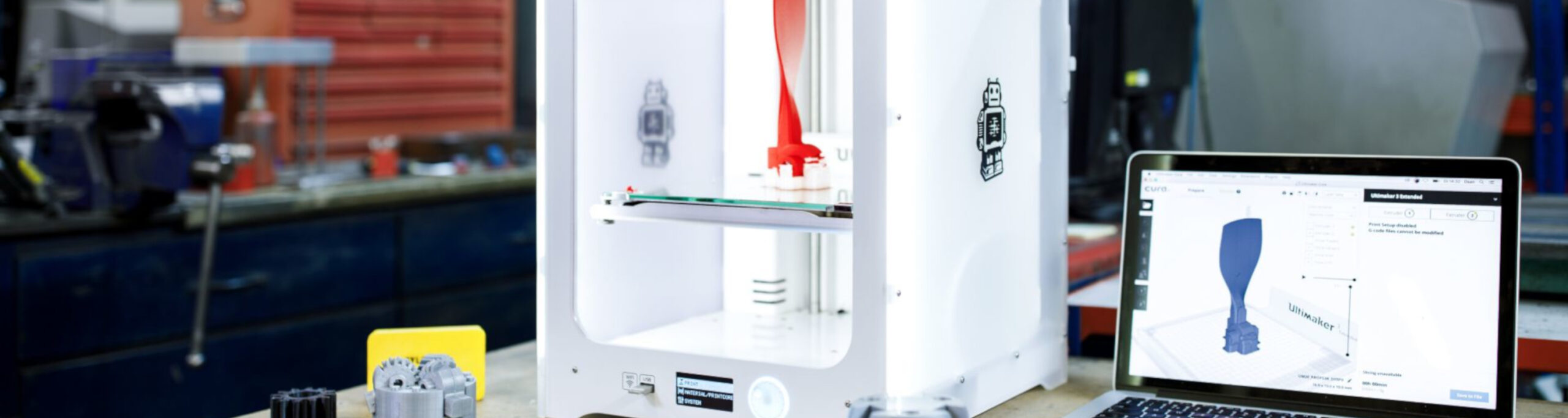

3D printing has become well established across a variety of industries, such as automotive, aerospace, and manufacturing. However, it’s also finding its way into the everyday workflow of other, less obvious applications. Here are four of our favorites.

1. Better product packaging

Creating packaging prototypes is a vital step in the design process for many companies, specifically those in the fast-moving consumer goods industry. Having a prototype that teams can actually see and feel is helpful in identifying potential problems before the design is finalized. However, prototyping can be expensive, especially if there are numerous iterations, so it is often outsourced.

Tove Almgren, Senior Packaging Technologist at Oriflame Cosmetics in Sweden, has successfully incorporated 3D printing into her design process. The company launches around 450 new products per year, 50 of which are brand new components that each requires several iterations before going to tooling.

“Our Ultimaker printer allows us to turn designs around quickly to show all actors involved in the development, giving them the opportunity to provide valuable input that we then use to discard unworkable concepts sooner and get to a final product quickly,” she says.

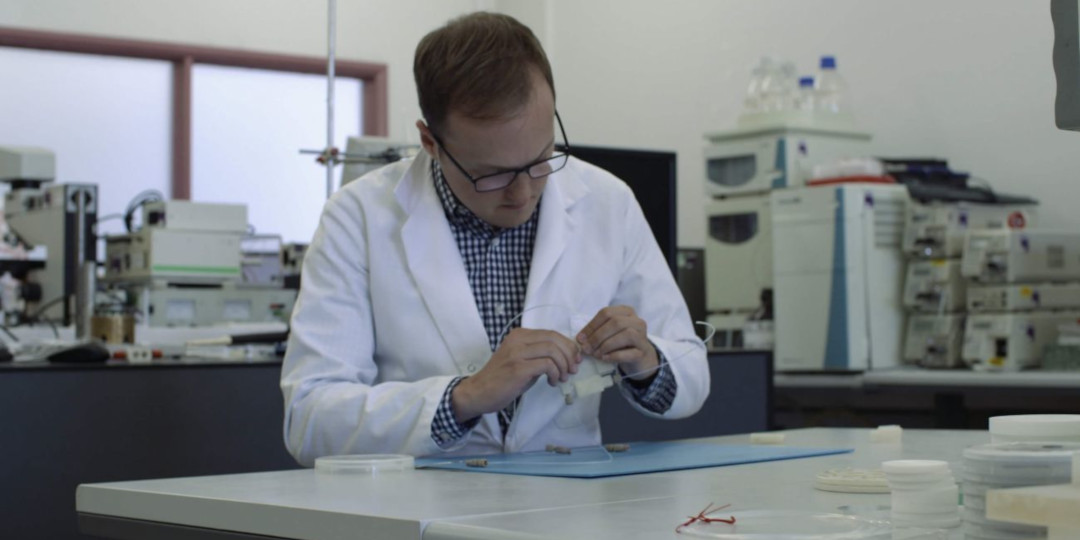

2. Scientific research

From creating tools that organize laboratory spaces better to functional prototypes that help researchers meet their highly specific needs, 3D printing is exceptionally beneficial when used in scientific research. Through CAD software, researchers can design a model unique to their own projects.

3D printing also expands potential collaboration between study groups. At Cardiff University, researchers are 3D printing devices that move small volumes of fluid, called microfluids. The design is easily shared and recreated in other labs, allowing others to contribute to studying how these fluids move.

“Because these printers are cheap and affordable, it’s a technology that we can share with our collaborators and bring microfluidic technology to other people and researchers who wouldn’t otherwise be using it,” says Oliver Castell, Group Leader at Cardiff University.

3. Fashion design

Stretching the boundary between function and form, fashion takes on new dimensions when incorporating 3D printing. Combining design and art, it offers the chance to express individuality on a scale that has previously been unachievable. When it comes to couture, personalization is key. And because 3D printing allows designs to be quickly created and produced on site, it opens up a new world of customization.

With semi-flexible materials, designers can incorporate new textiles and textures into their handiwork. From bags and buttons to complex creations with intricate geometries, the potential applications for 3D printing in fashion are endless.

Jessica Joosse, industrial design master’s student, has been incorporating 3D printing into her work with fastenings and detailed patterns. She believes that 3D printing will help connect fashion better to consumers. “The fourth industrial revolution will enable brands to make more personalized clothing, using new ways of manufacturing – like 3D printing and also body scan data,” she says.

4. Educational tools

One of the key benefits of 3D printing is that it localizes manufacturing and makes designs easily accessible. By sharing the STL files, collaborators can quickly download and print their own models using a 3D printer. In education, this presents the opportunity to create tools that aid learning. For example, printing out a geometric model can help students grasp concepts faster, while 3D printed replicas of historical artifacts get students actively engaged in their learning.

The benefits of 3D printing in education can also be seen in other ways. Fittle is a 3D printed puzzle that helps the blind and visually impaired learn how to read braille. Although learning braille can be empowering, it can also come with a price tag, especially in developing countries where access and resources are limited. This is why Fittle was founded by a group of designers, eye specialists, a toymaker, and independent global communication group Serviceplan. “Feedback has been overwhelming so far," says Christoph Bohlender, Creative Director at Serviceplan Health & Life. "More and more children are learning braille better with Fittle.”

As 3D printing grows and gains more traction as a tool within professional environments, the variety of applications is set to expand. Incorporating additive manufacturing into your business is simple, reliable, and relatively inexpensive when compared to traditional manufacturing methods. And with today’s comprehensive printing ecosystems that combine the hardware, software, and materials, exploring the world of 3D printing has never been easier.