Additive manufacturing (commonly known as 3D printing) is an increasingly valuable tool for business. Fabrication in-house can significantly reduce costs compared to outsourcing, and offers greater freedom to create more design iterations. The three dominating consumer 3D printing technologies used today are FFF (fused filament fabrication), SLA (stereolithography), and SLS (selective laser sintering). Each technology has its own benefits and limitations, but which technology is best for your business needs?

All 3D printing technologies are based on a common principle – a 3D CAD model is sliced horizontally into separate cross-sections, that are then printed sequentially on top of each other to form a three-dimensional object. However, FFF, SLA, and SLS technologies take fundamentally different approaches to printing these cross-sections.

FFF (fused filament fabrication)

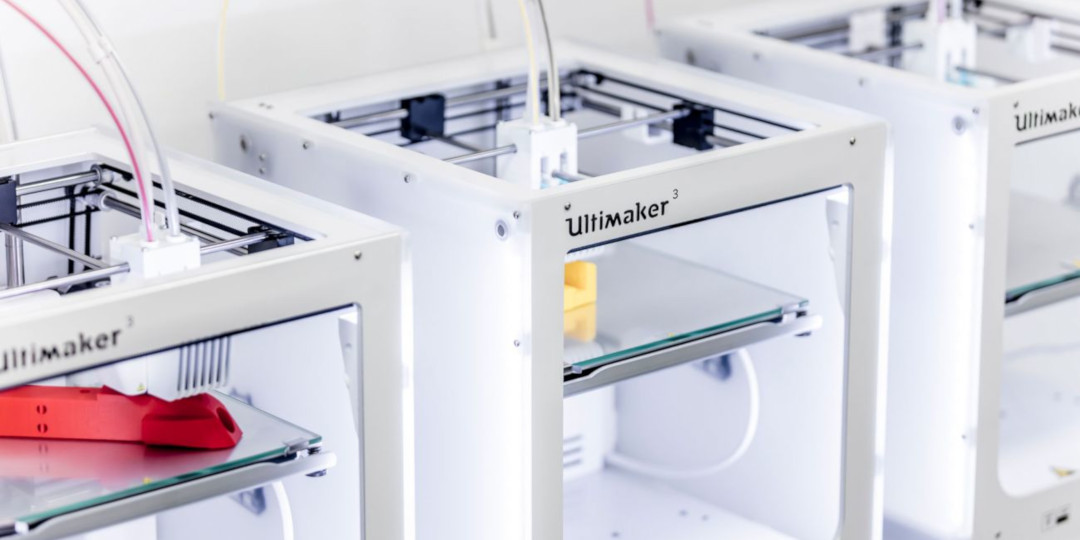

FFF is the most commonly used 3D printing technology, due to its ease of use and lack of reliance on harsh chemicals. FFF uses a thick string of raw material, commonly referred to as filament. Filament is a constant width of either 1.75 mm or 2.85 mm, and is typically a thermoplastic that is delivered on a spool. The FFF process extrudes the filament through a heated nozzle, which is mounted on a motion system that moves it around a build area. Melted filament from the nozzle is deposited onto a build plate, where it cools and solidifies to form a layer. The bed then moves down by a fraction of a millimeter to start another layer. The process is repeated until the complete object is formed.

Advantages

Equipment is relatively simple to operate and maintain

The equipment and process is more affordable and cost-effective than other major 3D printing methods

The process is relatively clean and doesn’t require the use of harsh chemicals

The compact nature of the equipment means it can fit on a desktop, or be rack-mounted

The entire process takes place in a single station – no extra equipment is required

A wide variety of materials are available, with various engineering properties

The relatively low price of equipment means that multiple printers can be used together, for flexible scalable manufacturing and shorter lead times

Disadvantages

Key takeaways

An FFF printer is ideal for an office environment, as the equipment is easy to operate and maintain, and the process doesn’t rely on the use of any harsh chemicals or post-processing stations. There is an extremely wide variety of consumables which are relatively inexpensive compared to the other methods. Consumables are distributed in the form of a filament on a spool, which is easy to use, and can be stored for an extended period of time.

FFF 3D printed parts may sometimes require support structures, but this can be avoided if the CAD design process takes the fabrication method into consideration. Dual extrusion makes it possible to use two materials in a single print. This can be used for aesthetic purposes, by using multiple colors of the same material. It can also be used for variation in mechanical properties, by using two different types of compatible material. Another possibility is using dedicated support material, such as water-soluble PVA support material which can print dissolvable support structures, or Breakaway support material, which can print support structures that easily peel away from the part. Using dedicated support material ensures that the final part has a smooth surface finish, for a high-quality part with minimal post-processing.

SLA (Stereolithography)

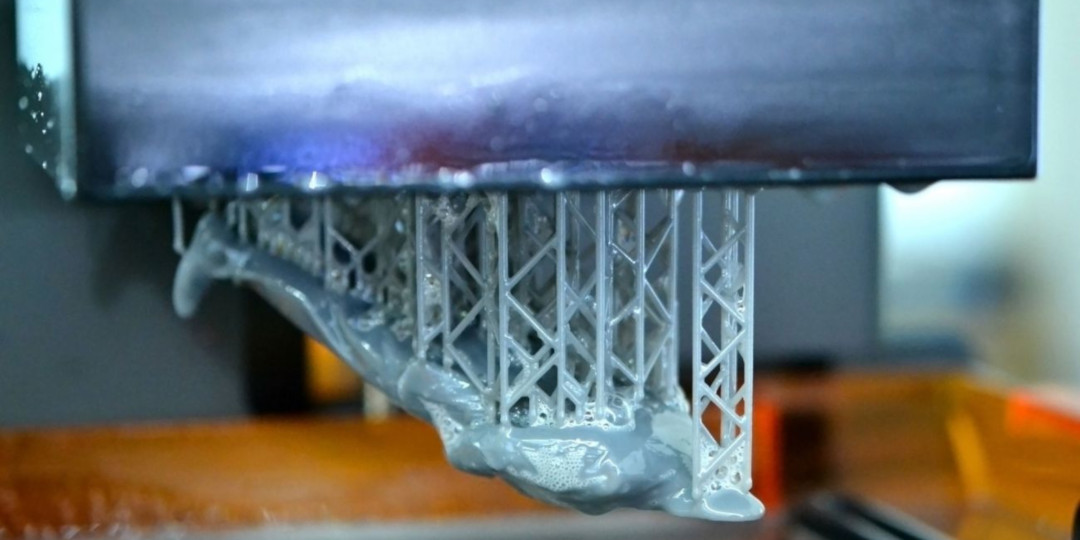

Another major 3D printing technology is SLA, which uses a UV-curable resin as a raw material. The resin is poured into a glass-bottomed container, which a build platform is submerged into. A UV laser or DLP projector shines UV light on the resin to selectively harden it into a horizontal layer of the CAD data. The platform then raises out of the container, allowing the uncured resin to level out. This process is repeated until a complete object is formed.

Advantages

Parts with complex geometry have a high-quality surface finish and the highest level of detail out of the three technologies, making SLA ideal for small-scale parts

Equipment is compact and relatively easy to operate

Multiple materials with various properties are possible to print using this method

Disadvantages

Consumables are unsafe to handle without gloves, smell unpleasant, and are flammable

Further curing is required during post-processing

Consumables are sticky and can cause workplace contamination if not cured properly

Support structures are almost always necessary, which leave artifacts on the surface of the print

It is not possible to combine multiple materials or colors in a single print

The build volume of desktop SLA printers is relatively small compared to the other two technologies

Parts must be prepared with holes so that uncured resin can drain out of closed structures

Key takeaways

SLA is well-suited to parts with complex geometry which require fine detail, but printed parts will need to use support structures in almost all cases.

Post-processing is a more complex process compared to FFF: parts need to be cleaned with harsh chemicals such as isopropyl alcohol, and need to be cured in a UV oven before they can be handled. Due to the use of harsh chemicals, a well-ventilated area for operation and post-processing is required.

The raw material is a resin, which is flammable, smells unpleasant, and has a limited shelf life. Old and new resin can’t be mixed together, meaning higher costs due to material wastage. The price of raw material is relatively high compared to the other technologies.

SLS (selective laser sintering)

The third major printing method is SLS, which uses a powdered raw material, typically a polymer. The powder is stored in a container, where a recoating blade distributes a thin layer of material onto the build area. A high powered laser fuses the small particles of material together, in order to form a single horizontal layer of the CAD data. The container then moves a fraction of a millimeter to start a new layer, and a recoating blade swipes across the build area to deposit a new layer of raw material. Unfused powder is recycled by sieving and mixing the sieved powder with unused powder. The process is repeated until a complete object is formed.

Advantages

Finished parts have no visible layers, although they can have a ‘grainy’ surface

Finished parts have relatively high mechanical properties in all directions (isotropic mechanical properties)

Support material is not necessary while printing

Disadvantages

The equipment is large making it unsuitable for the office environment

The raw material is a powder that can be hazardous if inhaled

It is difficult to switch materials or colors easily

Equipment and consumables are expensive to purchase, and operation and maintenance requires skilled labor that will incur further costs

The process requires a post-processing station and powder recycling station, which adds extra costs

The process can be uneconomical if the entire container volume isn’t used

Key takeaways

The freedom to design intricate, complex shapes without the need for support structures allows a lot of design freedom, and layer lines aren’t visible on the final part.

Cost is a major downfall – SLS is the most expensive solution of the three major 3D printing technologies in terms of initial set-up and maintenance. The complicated nature of the equipment also requires skilled labor to operate it, which adds further costs.

Printing with the maximum volume possible is recommended to avoid having lots of used powder, so it is not ideal for individual parts of small production runs.

Due to the use of high powered lasers and dust created by the process, SLS can be a hazardous process, and in combination with the size of the equipment, a specialized space will be required for installation.

Conclusion

These three major technologies each have their unique use cases. SLA is ideal for small objects with intricate features and details. SLS is ideal for larger, high-volume production and industrial print runs where the entire build volume is filled each time.

FFF users are able to hit the ground running quickly. The affordable, accessible, and versatile nature of FFF technology means that implementing an in-house 3D printing solution doesn’t require additional space or specialist staff to operate. Businesses are able to significantly cut development time and costs compared to traditional methods, and processes are more flexible, as products can be developed in an iterative fashion. FFF involves the least amount of post-processing and mess created out of all the major technologies, giving it a clear advantage over the alternatives for use in the office environment. As an added bonus, the widespread use of FFF 3D printing means there is a wealth of information and resources that are available for free.

For more information about how FFF 3D printing can streamline your in-house fabrication, visit our explore pages.