We don’t yet fully know what this “new normal” will mean for the global economy. But it’s clear that food and beverage manufacturers are facing bigger challenges than ever.

Changing consumer behavior, increasing costs, volatile market dynamics, supply chain instability. All of these and more are enough to worry even the most established players in the market.

Whether you’re a small supplier looking for lower cost production solutions, or a major producer targeting even higher output across global locations, we believe that 3D printing doesn’t just help – it changes the game.

And we're offering free a free playbook developed by our expert application engineers to help you take the first steps.

Commonly used tools can be ergonomically optimized in-house using 3D printing to make routine tasks more efficient

What difference can 3D printing make?

Even before the COVID-19 pandemic, many leading food and beverage companies had invested in additive technology to optimize their production.

Here’s a quick taste of the benefits of what our customers have experienced:

Safer work environments. 3D printed safety features, such as “lockout-tagout” (LOTO) devices and key systems have been used for years. But now, screen brackets, face shields, and door openers can be 3D printed to rapidly adapt workplaces to a post-Coronavirus world

Decrease lead-times and costs. The traditional process to get a spare or replacement part can be time-consuming and expensive. With 3D printing, you can produce many parts in-house – at a fraction of the cost

Increase line uptime. Minimize short stops, speed up changeovers, and avoid unplanned downtime by having your own on-demand production solution close to your packaging line

Better warehousing. Inventory takes up space and needs to be monitored. So instead of carefully managing stock, you can 3D print parts on demand, whenever they are needed

Faster time to market. 3D printing makes it possible to perform almost immediate tooling changeovers so your product range can keep up with changing demand, or test new products on the line itself using final materials

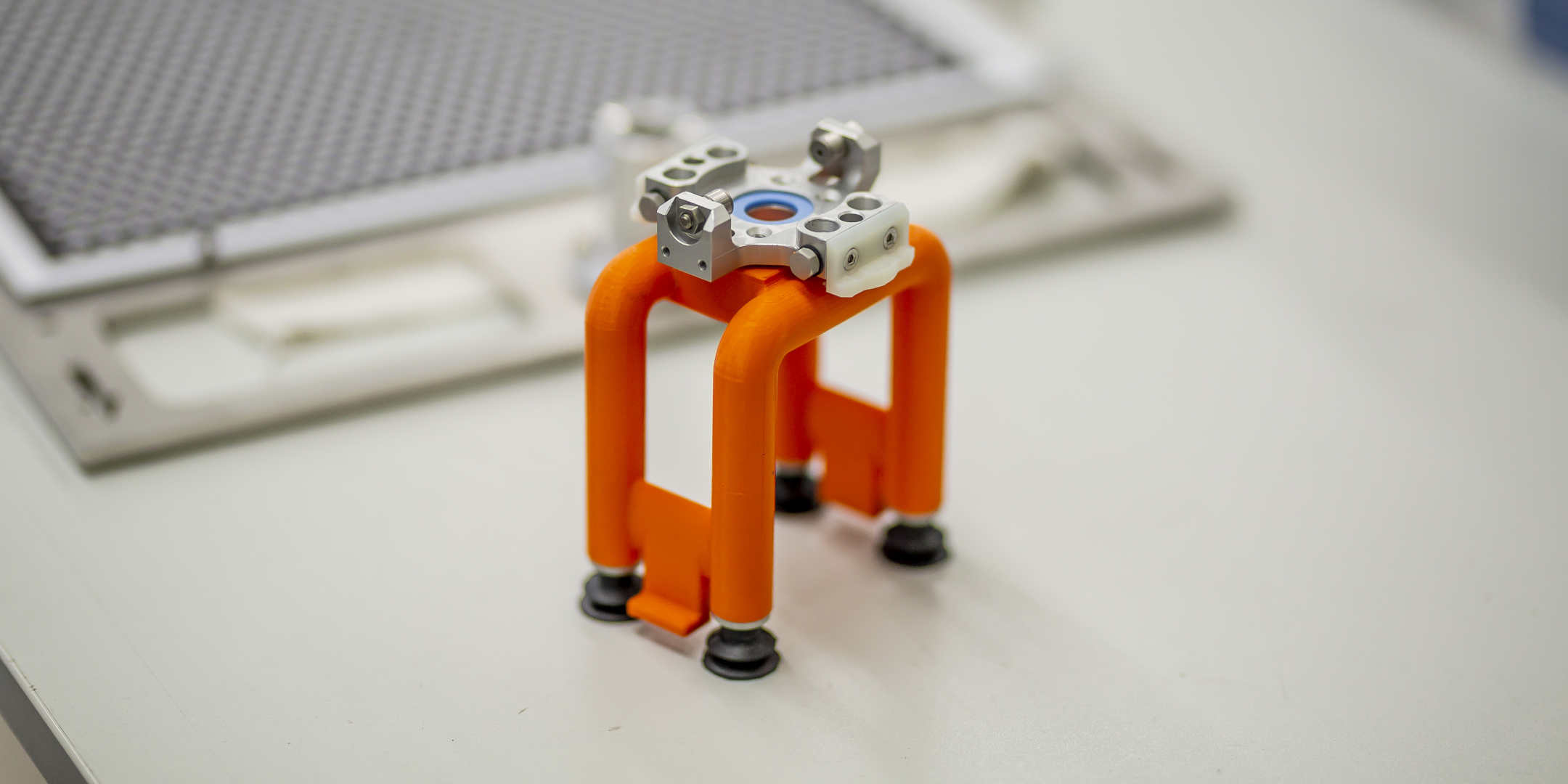

Complex suction assemblies can often be 3D printed with fewer parts and at a lower cost

How to get started?

Look around a typical manufacturing plant and there will be many parts and tools that could be entirely or partly 3D printed in order to enable these sorts of benefits.

Among the most applicable for food and beverages manufacturers are:

Want to see some of these in action? Read our customer success stories to see how manufacturers from Heineken to Gerhard Schubert GmbH are putting 3D printing into action already.

Change the game with our free playbook

Our free playbook on 3D printing for food and beverage manufacturers features will help you unlock these applications and meet the challenges of an uncertain future.

Written by the Ultimaker application engineers who have worked together with some of the leading food and beverages brands, it reveals:

The two simple criteria our application engineers use to identify and prioritize 3D printing applications that will achieve the fastest ROI

How 3D prints can replace (and even outperform) metal parts

The top five questions to ask when scanning your lines to identify new 3D printing opportunities

A complete category checklist to ensure no potential 3D printing application goes undiscovered

And much more...