Engineering is about creating designs that work as efficiently as possible. Wasted time is wasted money, and to have a project stall because of an unforeseen design flaw or a delay in the supply chain can be as frustrating as it is costly. That’s why control is so valuable – control of your time, control of your costs, control of your entire process. And 3D printing is all about control.

Using 3D printing, engineers can create new prototypes – even those with complex internal structures and geometries – address problems, and find solutions, without ever leaving their working environments. The right 3D printer holds the potential to shrink development time from months to days, encourages collaboration between peers, and enables the creation of rapid prototypes and end-use parts – ensuring that projects are finished on deadline, within budget, and bring about desired results.

Design flexibility

When creating custom parts for small bore motorcycles, engineers at MNNTHBX (Man in the Box) know that the design and testing phases both have the capacity to be time-consuming and expensive, especially when using materials such as aluminum.

Using Ultimaker 3D printers, MNNTHBX is able to increase the flexibility of its designs and improve product test phases. It has also seen a marked increase in its return on investment, saving upwards of $1,000 per printed part.

A 3D print mounted on a part created by small-bore motorcycle parts manufacturer MNNTHBX

“Our printer basically paid for itself the first time we saw a product through prototyping. Being that we prototype roughly 15 products annually, the cost savings become apparent,” Greg Hatcher, Owner of MNNTHBX, said. “3D printing on Ultimaker mitigates risk and opens the door to creating working concepts on extremely low investment. Long gone are the days of spending thousands of dollars running multiple prototypes through traditional CNC machining methods. When we take a design to the machine shop, we know before we start that it’s a fully functional design meeting our standards.”

Proof of concept

It’s one thing to create a bold new design – it’s another entirely for that design to work as intended. Sending those designs into space adds an additional level of complexity. Honeybee Robotics has contributed critical planetary analysis technology incorporated into three of NASA’s Mars mission, including planetary drills and sampling systems on the Curiosity rover.

Honeybee Robotics’ projects demand complex, load-bearing metal parts that can survive harsh environments. Using 3D printing, engineers were able to quickly and cheaply test concepts and establish project parameters, rather than relying fully on methods of outsourced fabrication, which were slower and more costly.

A soil scooper partially created with 3D printing by Honeybee Robotics

“A lot of what we do is to build subsystems and then test their performance,” says Yoni Saltzman, Project Engineer, said. “How fast they are, things like that. So physically building key elements of the robot is what the printer allows us to do cheaply and quickly.”

End-use parts

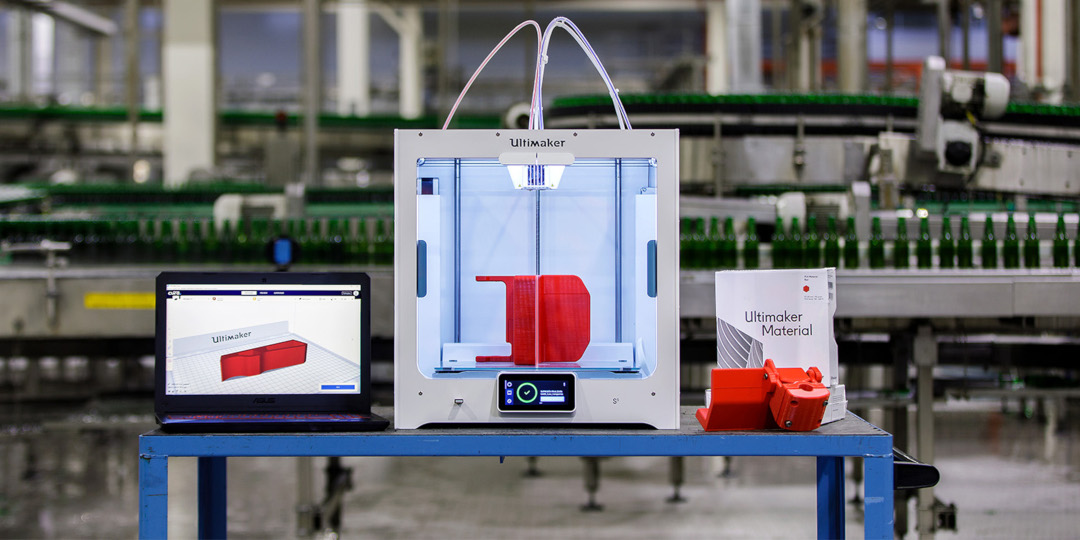

At a Heineken brewery in Seville, Spain, Ultimaker printers are used to create parts in-house, which are then implemented on its bottling line, replacing metal parts that are heavy, and tend to knock bottles over. The redesigned 3D printed parts are lighter and cheaper alternatives, and now play active roles in Heineken’s manufacturing environment.

“3D printing has proven to be a technology that helps us, brings value to us, and enables our people to work more efficiently,” Juan Padilla, Packaging Manager at the plant, said.

Low-volume production

3D printing can also play a part in low-volume production of complex parts. IMI Precision Engineering is a world leader in motion and fluid control technologies. It needed a new additive manufacturing technique that would allow the creation of geometrically complex parts. By turning to 3D printing and the Ultimaker S5, the firm saved thousands of dollars in part creation – and nearly 2,000 hours per year in labor.

A finished complex print created by IMI Precision Engineering

“The Ultimaker S5 offered the best value, with the size and materials we needed to print all the parts,” Kathryn Jones, an IMI Graduate Engineer, said. “It added new capability to another 3D printer that we had purchased last year, with lower costs for low volume parts and improved manufacturing efficiency.”

Ready to introduce 3D printing into your workflow?