MATT Architecture creates architectural models in central London. They use 3D printing to quickly reiterate the models they are working on, which saves a lot of time and development costs. Also, by being able to print out their designs they can engage their clients in an early stage of the planning process, which makes it easier for them to convey their proposals.

3D Printing complex shapes

MATT Architecture works on everything from bespoke residential buildings to commercial development. Before they started using 3D printing, models were hand-made by cutting pieces of paper or cardboard, for example. This is a good solution for conveying basic ideas, but as the models become more complex it can get very labor-intensive to work out all the geometries. This is where 3D printing comes in as a real time-saver. As Daniel, one of the architects working at MATT explains:

Whilst architects have always constructed physical models to test and evaluate design decisions, 3D printing opened up the possibility of increasing the frequency and complexity of this iterative process between digital model and physical artifact.

MATT Architecture started using 3D printing after Matt White funded a kickstarter 3D printer. They're currently using two Ultimaker 2's and an Ultimaker 2+, and plan to implement an Ultimaker 3 next. A big project they're currently working on is the Ilona Rose House project, a stunning 300,000 sqft new-build, mixed-use redevelopment in central London.

Ilona Rose House in its broader context

Fast reiterations

Throughout the planning process of the Ilona Rose House project, MATT found they needed to reiterate the design a number of times. 3D printing proved to be an invaluable tool for prototyping quick yet beautiful models that help engage the planners in the planning process and transmit the ideas they have for the build.

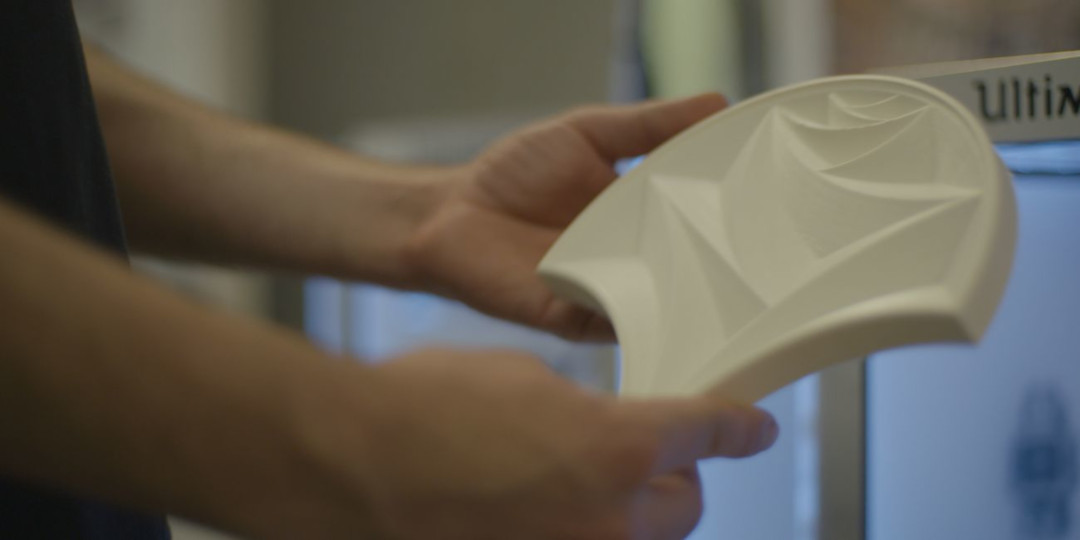

For the building's facade, they 3D printed the proposed pattern in full size on their Ultimaker. From this, they cast a mold and finally produce a tile that they can use when communicating to the site's planners and manufacturers. As Daniel put it:

I see 3D printing as an essential tool for the development of our architectural ideas in practice, a way of testing the limits of possibility in the comfort of our own studio.

The 3D printed facade pattern of the Ilona Rose House

Inclusive architecture with 3D printing

As this case illustrates, 3D printing can be used to greatly reduce the development time of architectural models. It also allows for greater engagement in the planning process by being able to quickly print out sturdy designs to transmit the architect's ideas and proposals. Discover the possibilities of 3D printing in architecture by checking out our explore pages: