If you want to increase efficiency, reduce production time and costs, or optimize product time-to-market, now is a perfect time to get started with 3D printing. This powerful technology has quickly become an essential industry tool, with its effectiveness confirmed by Ford, Volkswagen Autoeuropa, and L'Oréal, who have successfully used it to streamline processes and slash production budgets by thousands of dollars.

In an increasingly professional market, desktop 3D printing is driven by hardware innovation, but developments in materials and software are contributing just as much. 3D printing software such as Ultimaker Cura is used by thousands of professionals to prepare millions of prints every month, and an increasing range of advanced 3D printing materials make serious engineering applications possible at a fraction of the cost of conventional methods.

Reliable hardware that’s easy to use

Build quality. FFF – or fused filament fabrication – hardware today is supplied as a fully assembled unit. An example of this is the Ultimaker S5, which is manufactured by trained staff at ISO-certified facilities in Europe and the US, and tested under strict quality conditions to be compliant with major governing bodies to ensure maximum safety and solid performance.

Ultimaker's manufacturing facility in the Netherlands

User experience. To avoid user frustration, today’s desktop 3D printers keep the user at the heart of the experience. Integrated touchscreen interfaces and built-in programs automate common operations, and network connectivity removes hurdles from the production workflow, so that jobs can be sent and progress monitored remotely over your local network. Dual extrusion printing enables multiple materials in a single print, and print cores for the Ultimaker 3 and Ultimaker S5 make nozzle swapping quick, easy, and tool-free to keep uptime to a maximum and user maintenance to a minimum.

The Ultimaker S5 features a touchscreen interface, for easy operation

Materials that solve real-world problems

Material choice. 3D printing is becoming increasingly application-driven, and as a result material choice has expanded significantly. Respected chemical companies such as BASF, DuPont, Owens Corning, Clariant, and DSM now offer their own materials for high-strength, chemical-resistant, ESD safe, and other characteristics that unlock new applications, solve real-world problems, and undercut the cost of conventional methods.

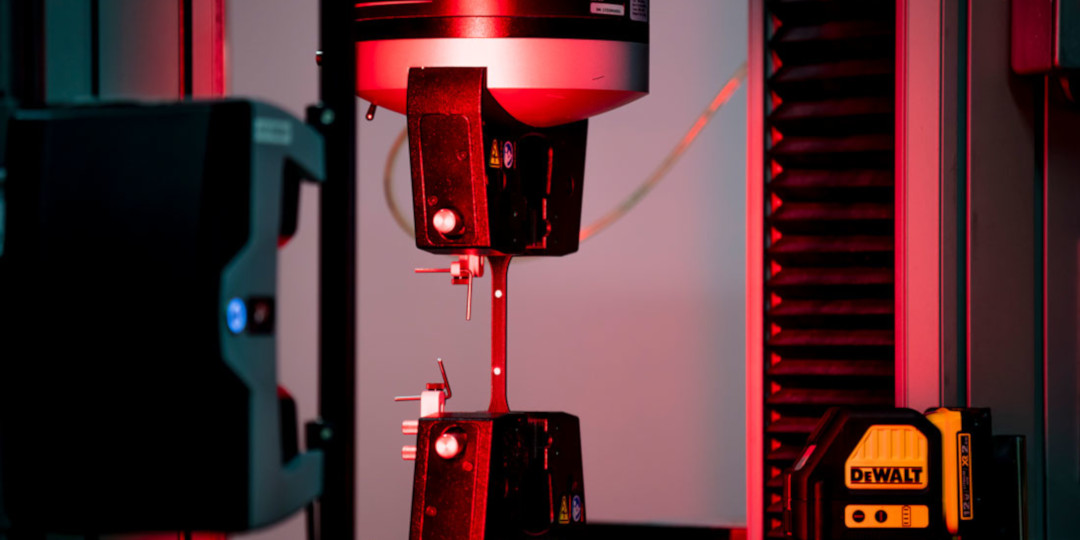

Materials are tested to work with hardware reliably

Dual materials. Multi-extrusion printheads have extended the possibilities of FFF technology, opening up dual color parts, parts with varied engineering properties, or specialized support material. Water-soluble materials have overcome limitations of the technology, enabling parts with complex geometries, or moving components that can be printed as a single part.

Tensile testing an XSTRAND™ sample printed on the Ultimaker S5

Preconfigured profiles. Have you ever spent too long configuring settings before you have a successful iteration in your hands? Print profiles from material manufacturers offer fine-tuned settings for 3D printing hardware. With this, the ideal settings for a material are selected and populated in slicing software, so that you can prepare, hit ‘print’, and have confidence that the print you started in the evening is there waiting for you in the morning.

Software that meets the needs of every workflow

3D printing software has found a balance between user-friendliness and granular control. Code optimizations use material with increasing efficiency and produce parts with better strength characteristics with each subsequent release, but innovations in desktop 3D printing software do more than contribute to accurate, reliable results; they also add greater flexibility to the 3D printing workflow.

The Marketplace in Ultimaker Cura

Integration. Slicing software such as Ultimaker Cura ties together different elements of the workflow into a centralized platform. Plugins extend the core functionality in various directions to suit a range of use-cases. One example of this is integration with industry-standard CAD software, such as SolidWorks, AutoCAD, or Siemens NX, which enables users to rapidly export designs without the need for different exchange formats.

Automation. The emergence of printer management software has brought about accessible scalable manufacturing, allowing centralized access to multiple users. The low-risk investment of a single 3D printer means more can be added quickly and easily when needed. These kind of software solutions also include frameworks to measure performance and provide detailed reports for better-informed manufacturing and forecasting.

Ultimaker S5 3D printers controlled by Cura Connect

Time to give 3D printing a second look

This is just a brief glimpse into the trends the industry is experiencing, and anyone entering the 3D printing world today should be well informed of the potential. We provide a range of knowledge and resources, so you can make informed decisions before making an investment.