Welcome back to our application spotlight series, where we showcase real-world 3D printed parts that drive smarter, faster, and more efficient manufacturing. Each week, we highlight practical examples that show how additive manufacturing helps solve complex industrial challenges.

This week, we’re focusing on a custom 3D printed board support for sensors, a compact but critical component used in agricultural machinery to ensure stable sensor performance in the field.

Stronger support for smarter systems

In the agricultural equipment sector, precision and durability go hand-in-hand. Sensors must remain stable and aligned under harsh working conditions - vibration, dust, moisture, and mechanical stress are all part of the environment. When a key board support component began showing signs of wear, one industrial company turned to additive manufacturing for a faster, more robust solution.

Originally manufactured in ASA, the part performed well - until stress from regular tightening and field conditions led to premature wear. That’s when DP3D stepped in.

Engineering a better fit with PET CF

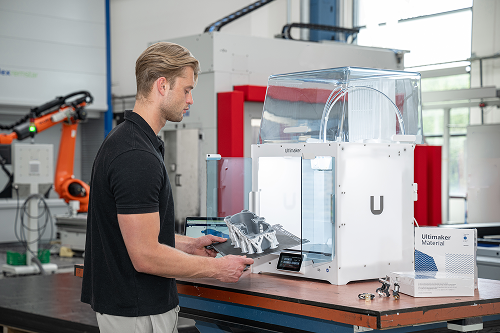

To improve part reliability and longevity, DP3D recommended switching to PET CF (carbon fiber-reinforced PET). The result? A stronger, longer-lasting board support with improved resistance to environmental and mechanical stress printed with the help of UltiMaker S6.

Why PET CF? It offers:

- High mechanical strength, ideal for secure tightening without deformation or cracking

- Low moisture absorption, essential for outdoor applications

- Signal compatibility, ensuring that electronic functionality isn't compromised

With this material upgrade, the company achieved greater reliability in the field - and reduced the need for frequent part replacements or redesigns.