At this very moment there are huge amounts of waste plastic, vast amounts in fact, and only 10 to 12% of it is being recycled. The rest ends up in the environment all over the world, even in our food, it literally ends up everywhere. Enter Perpetual Plastic Project – a collective of engineers looking to change the world by reducing the amount of plastic.

We really want to make a difference in the world, not just by talking about what is wrong with it, but by showing how things can be done differently by working with existing systems. The result is Perpetual Plastic.

- Jonas Martens, co-founder

Their aim is simple. You take waste plastic and turn it into something useful – plastic that’s perfect for 3D printing! This creates a circular economy where the material from the initial product can be used for the next. A pretty good idea in our books. It’s why we sponsored PPP back in 2012 to give them the kickstart they needed to fulfill their dream. And we’ve stayed in close contact ever since.

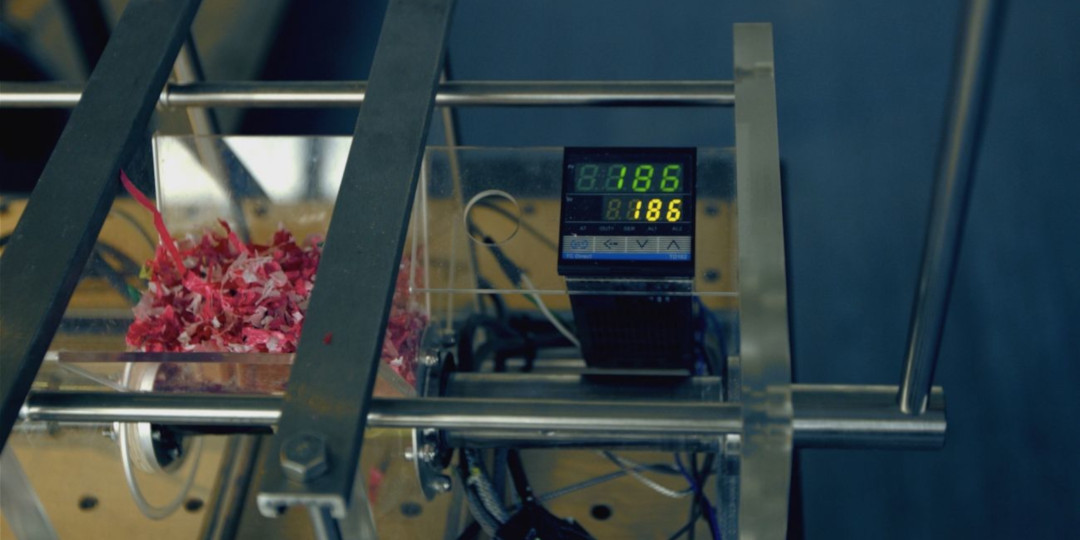

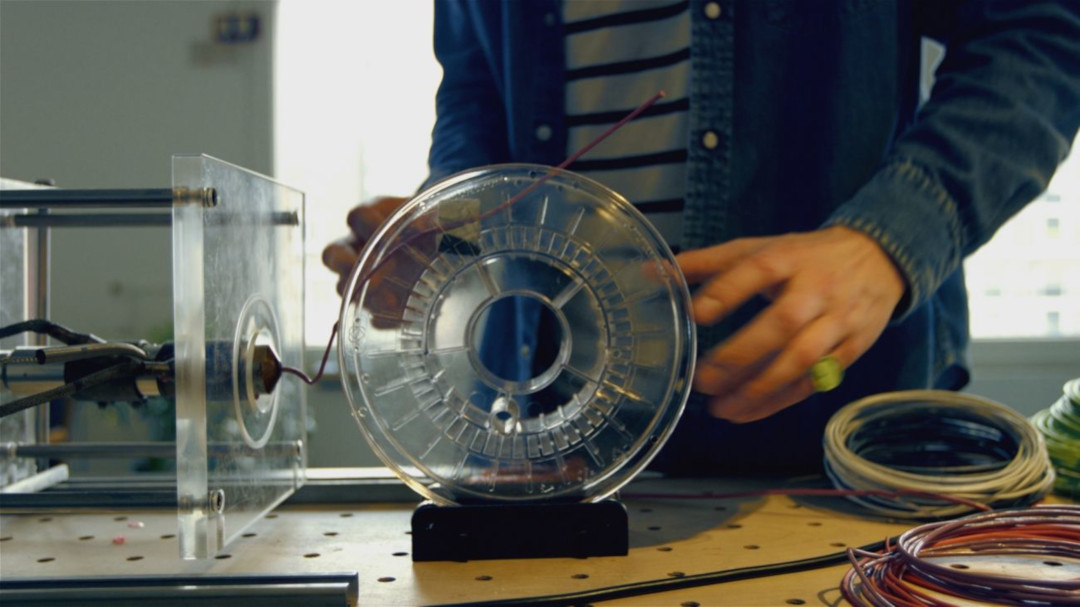

From plastic waste to useful filament

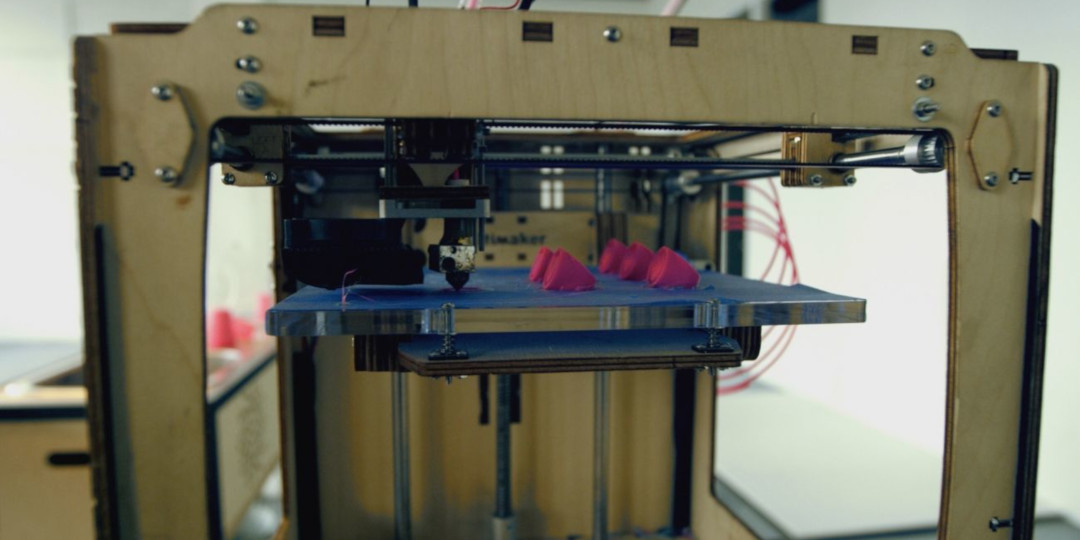

This original sponsorship came in the form of an Ultimaker that was used at one of the Netherlands’ biggest festivals. It helped to inspired the crowd to get involved with PPP’s recycling philosophy by asking them to collect their cups, clean them, shred them and turn them into plastic which could be used to 3D print a ring – which they could take home.

Rings printed with recycled filament

Since then, they’ve been going from strength to strength and they now even have a material of their own, made from recycled materials such as PET bottles or car dashboards. They’re very careful to use only recycle streams that are both safe and consistent. This filament is available via their ReFil brand.

ReFil's recycled PET filament

Jonas: “We believe in the local production of useful products. If you make new plastics, you usually need new raw materials like oil, and history has taught us on many occasions what the effects are. So we want everyone to start using recycled plastic wherever they can because the quality is equal to new plastic."

He continued: “We also specifically chose to work with Ultimaker as their machines use an open filament system and are designed and built to a very high standard – this means a better quality of print and in turn, fewer people are throwing away ‘bad’ or failed prints.”

We’ll continue to work closely with the talented people at Perpetual Plastic Project and lend a hand whenever we can. It never ceases to amaze us what people in the 3D printing community can do!