Being able to see is something many of us take for granted. But for millions of people around the world, especially those in third world countries, the possibility of losing this vital sense is a very real and scary prospect – one that can happen simply due to the lack of expensive examination instruments to help diagnose treatable and preventable blindness.

oDocs Eye Care

For Hong Sheng Chiong, a newly qualified ophthalmology registrar – junior eye doctor – this simply wasn’t good enough. “I believe sight is one of the most important sensory perceptions. It’s one of those senses that if you lose it, it's going to affect your independence, your work, your confidence and your self-esteem.” So Hong set about creating a remarkable examination device, one that’s not only very accurate and inexpensive, but that can be created and used in the most inaccessible places. To achieve this, Hong founded oDocs Eye Care, a group that creates open source medical equipment for eye diagnoses.

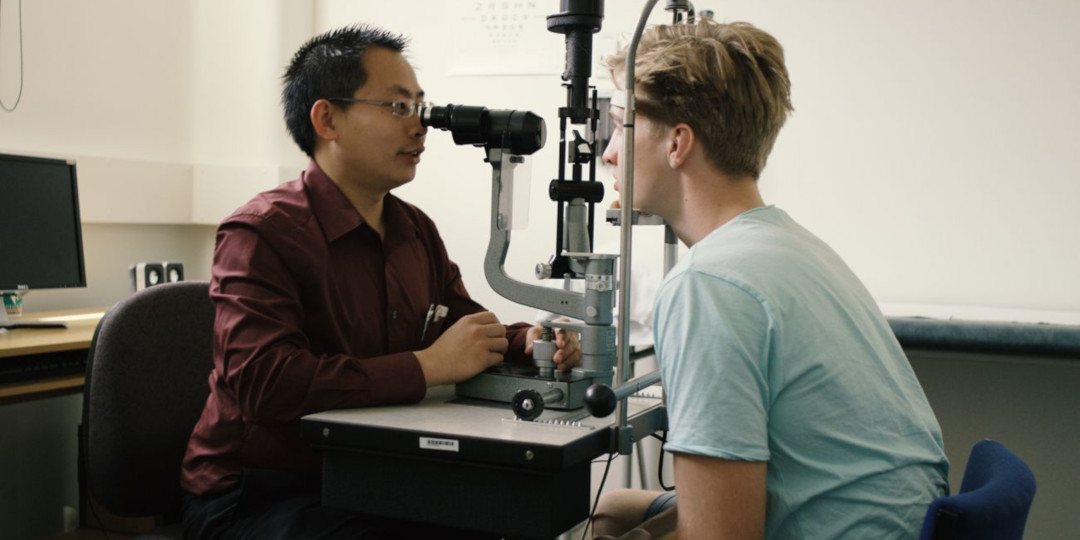

Hong using a traditional slit lamp microscope, one of the machines his kit replaces

3D printed eye examination kit

Together they've used an Ultimaker 2+ to create a smartphone retinal imaging adapter and anterior segment adapter. These cheap adapters are capable of achieving the same diagnoses as complicated hospital machines, like slit lamp microscopes and fundus cameras, that costs many tens of thousands of dollars. These incredible open source 3D printed devices are capable of achieving a 40 degree field of view with 10 times magnification – perfect for examining the intricacies of the human eye. And as it’s open source, anyone in the world can download it, print it and use it.

Creating a $50 imaging kit in just 4 hours

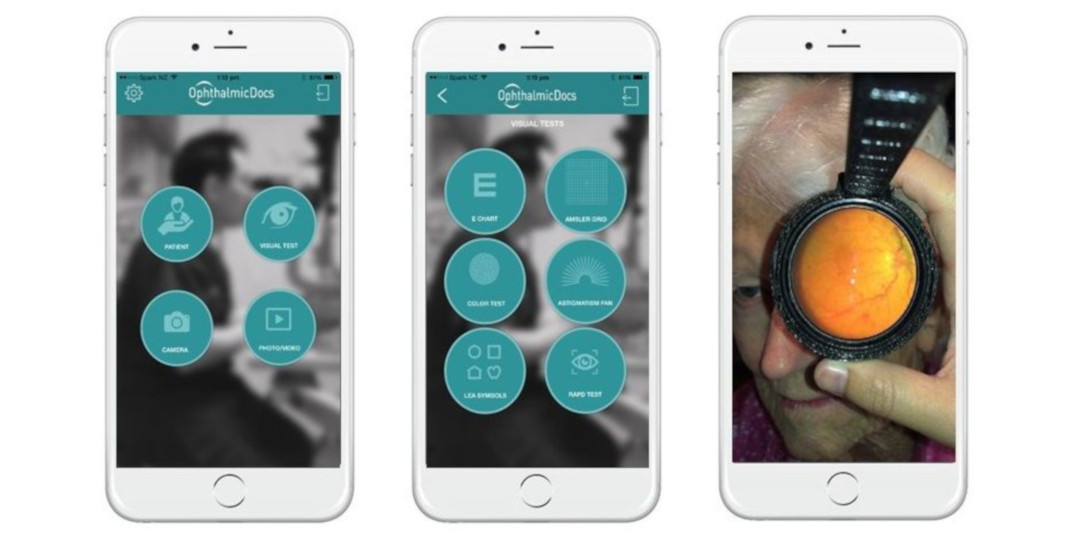

With just a few accessories such as a couple of inexpensive lenses and nuts and bolts, these adapters can be assembled in under 10 minutes. Once done, all you need to do is clip them on to the top of the smartphone and turn on the oDocs Eye app. That’s it. You now have a fully functioning eye examination kit for around $50.

The oDocs Eye app in action

Using the Ultimaker 2+

As you might expect, the design requires a high degree of accuracy – a task their Ultimaker 2+ achieves with ease. It means the team can easily 3D print eye examination kits, time and time again. In fact, to print an entire set on their Ultimaker 2+ takes just 4 hours for the retinal adapters, and 20 minutes for the anterior segment adapter.

“With the Ultimaker 2+, it’s even easier for oDocs to achieve what we need. First of all the new feeding mechanism makes it really easy to use, and secondly we’re very impressed with the print head. It allows us to change the size of the nozzle and print highly detailed small objects, or fast prototypes.”

Seeing the person you helped triumph, or say thank you or smile back at you. That’s what really gives me the motivation to keep working.

Hong isn’t motivated by money – in fact he doesn’t plan to make any money at all from the project. Instead, his motivation is to positively affect people’s lives. “It’s like volunteering to help someone and what you get from that is seeing the person you helped triumph, or just as simple as that person saying thank you or smile back at you. That’s what really gives me the motivation to keep working.”

We’re very inspired by oDocs’ story and can’t wait to see how their story unfolds – not to mention learning about the lives they will change forever. And don't forget to check out their designs on Youmagine.

Disclaimer: Ultimaker 3D printers are designed and built for Fused Filament Fabrication with Ultimaker engineering thermoplastics within a commercial/business environment. The mixture of precision and speed makes the Ultimaker 3D printers the perfect machine for concept models, functional prototypes and the production of small series. Although we achieved a very high standard in the reproduction of 3D models with the usage of Ultimaker Cura, the user remains responsible to qualify and validate the application of the printed object for its intended use, especially critical for applications in strictly regulated areas like medical devices and aeronautics.