Boyd Goldie, an orthopaedic surgeon working in a private hospital in London, treats patients that range from emergencies to non-emergency elective problems covering a whole host of upper limb surgery.

Surgical planning using 3D printed bone models

Ultimaker 3D printers are being adopted by many different industries including architecture, engineering, and medicine. What’s inspiring is that they are now being actively used by healthcare professionals not only to educate patients about their condition, but also to plan complex surgeries – even using the models during the operation as a guide.

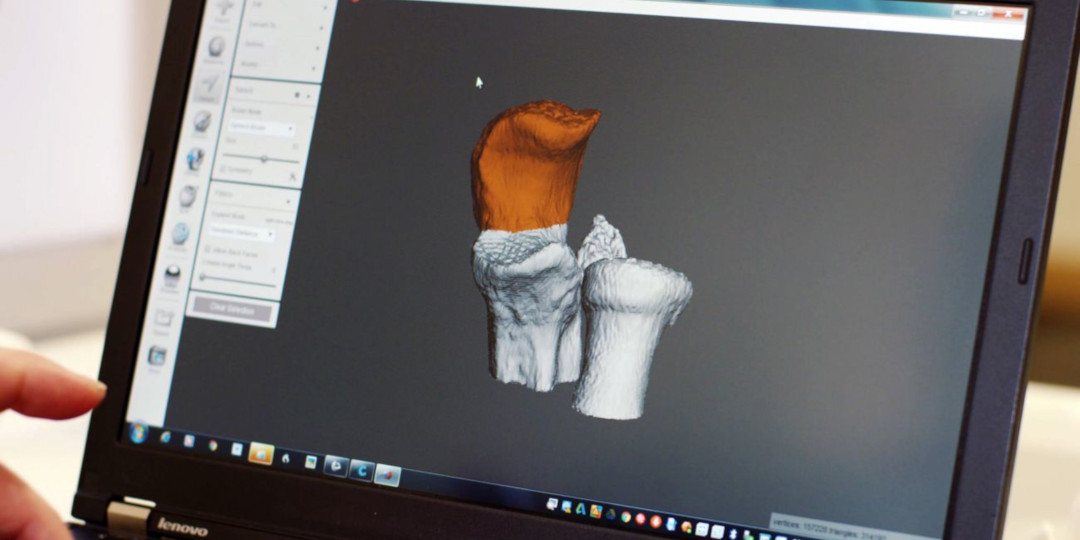

To help him prepare for surgery, his radiographers take a CT scan of the patient’s problem and save the data to a CD for Dr Goldie to review. He can see a virtual 3D model of the bone on screen, but as he remarks, “There’s nothing like holding a model in your hands, thinking about where it is in the body and working out how you’re going to fix the problem.”

With modern radiology software you can get a virtual model on-screen, but there’s nothing like holding a model in your hands

To get a 3D printed model, ordinarily he’d have to send his scans off to an external supplier, but this can take weeks and cost hundreds of pounds, as Dr Goldie says, “This is no good if you have a guy with a broken wrist and you’re going to operate tomorrow”. Instead, Dr Goldie converts the medical scan to a printable model using free open source software. With his Ultimaker 2+, he is then able to print the bone for himself in a matter of hours – depending on the size of the bone he needs to print.

A lot of it is to do with me as a surgeon, helping me to plan my operation, give me a better understanding of what I’m dealing with so I don’t have any surprises when I come to do the operation

The end result provides a host of benefits to both Dr Goldie and the patient. The patient receives a much deeper understanding of their problem and what the doctor is going to do, and some patients find it so enlightening they ask for a copy of the model.

And for Dr Goldie the benefits are quite clear: “A lot of it is to do with me as a surgeon, helping me to plan my operation, plan where I’m going to make my incision and give me a better understanding of what I’m dealing with so I don’t have any surprises when I come to do the operation.”

If you're interested in learning how Dr Goldie turns medical scans into printable objects, you'll be happy to learn that we will be featuring a print guide on the procedure from him soon! Stay tuned.

Disclaimer: Ultimaker 3D printers are designed and built for Fused Filament Fabrication with Ultimaker engineering thermoplastics within a commercial/business environment. The mixture of precision and speed makes the Ultimaker 3D printers the perfect machine for concept models, functional prototypes and the production of small series. Although we achieved a very high standard in the reproduction of 3D models with the usage of Cura, the user remains responsible to qualify and validate the application of the printed object for its intended use, especially critical for applications in strictly regulated areas like medical devices and aeronautics.