Did you know? Ultimaker Cura users worldwide prepare over 2 million prints per week.

Now, that’s impressive!

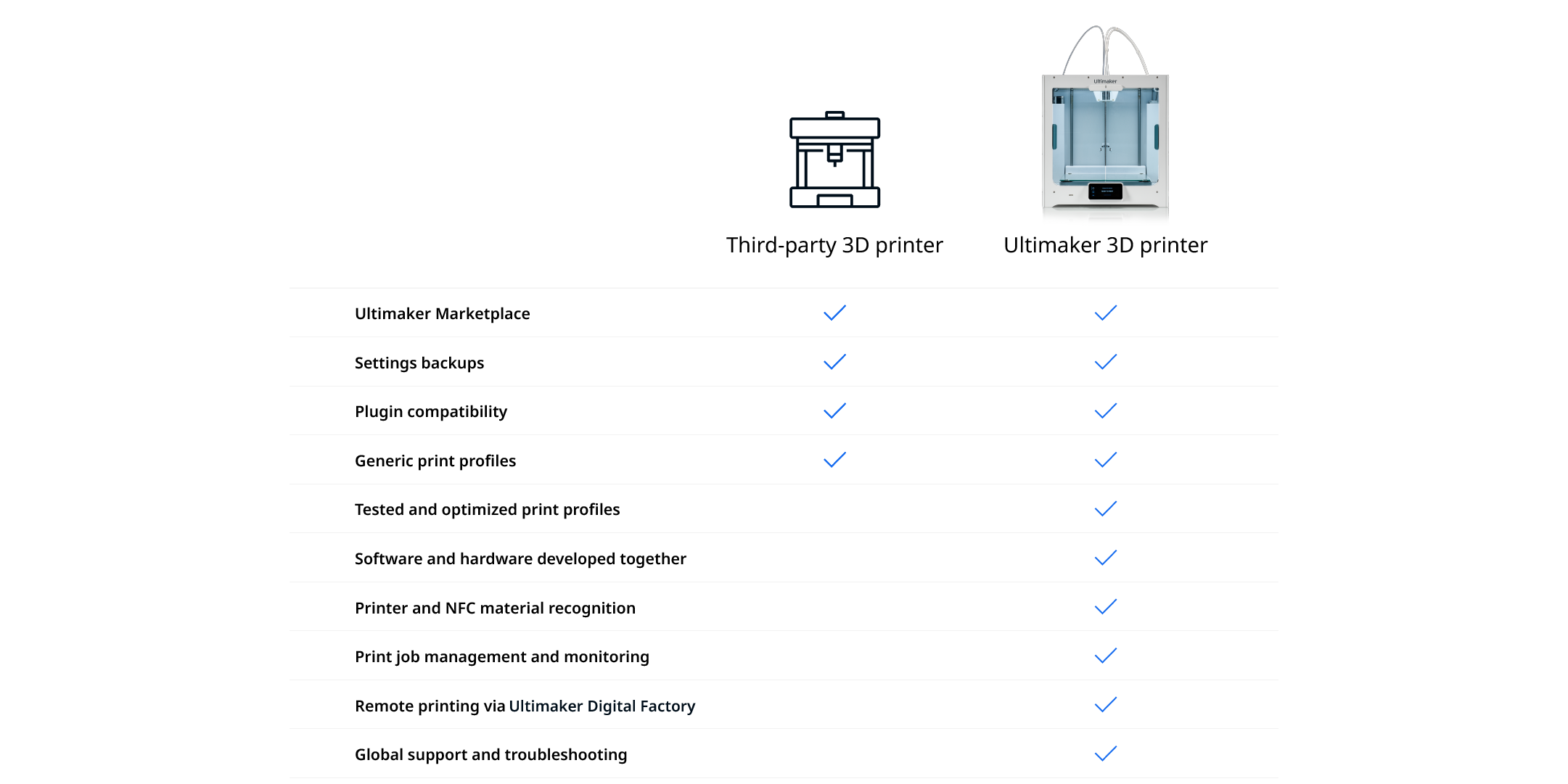

But if you’re someone who doesn’t send their print to an Ultimaker 3D printer, then you’re missing out on a ton of functionality:

Or scroll down to learn how these software and hardware integrations could improve your 3D printing experience and print quality.

Save time with predefined print profiles

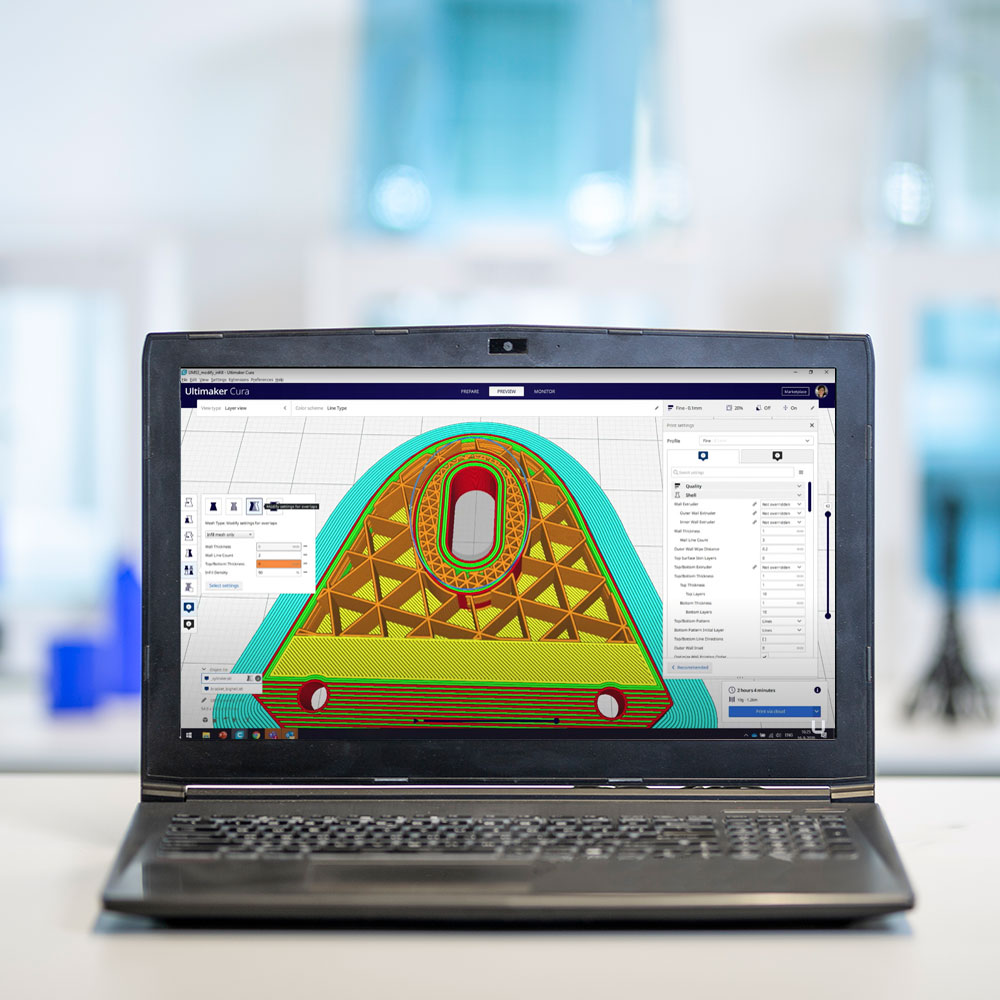

Ultimaker Cura gives you access to over 400 searchable parameters via the ‘Custom’ print settings button. With these, you have almost unlimited control to adjust and improve your print quality for any 3D printer.

Ultimaker Cura gives you a high level of control over your settings, but adjusting and testing takes time

Of course, changing and testing even a few of these settings takes time. For busy engineers and designers, this is where preconfigured material profiles become a big time-saving feature in Ultimaker Cura.

Print settings profiles are the result of Ultimaker's effort to make the 3D printing process simpler and more reliable. To give you an idea, here’s a breakdown of what it takes to create a new print profile:

Up to 100 print settings are tuned to achieve a basic profile that performs well for common challenges like overhangs and build plate adhesion

This profile is expanded across three layer heights

They are tested for 30 days (on 8 to 12 Ultimaker printers) and optimized for visual quality and mechanical properties

These settings are then expanded for all Ultimaker 3D printers, using all Ultimaker accessories and across all print core sizes

In total, a print profile for a brand-new material takes up to six months to develop and test. And there are almost 250 print profiles supported in Ultimaker Cura.

For owners of Ultimaker 3D printers, we invest all this time so you don’t have to. The result? 3D print preparation that keeps pace with your innovation.

And the work doesn’t stop there. All those profiles are maintained and updated as Ultimaker Cura behavior is improved, firmware updated, and new hardware features added.

Which brings us to…

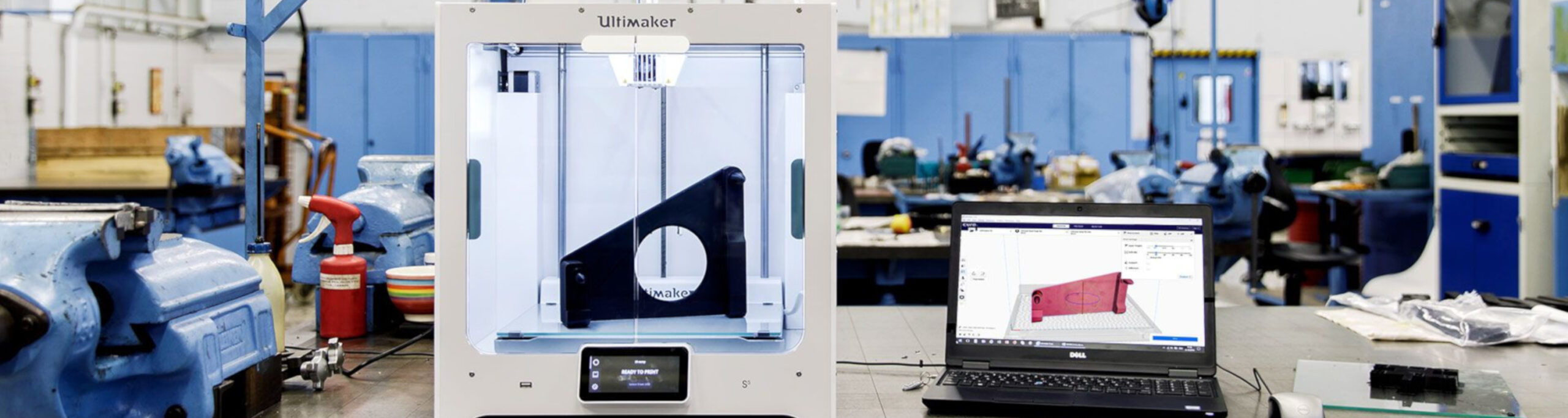

Software and hardware developed in lockstep

Ultimaker Cura and Ultimaker hardware are developed under the same roof. They share the same roadmap.

But what difference does that make to you?

Let’s say a new Ultimaker printer is released with a new hardware feature. For example, in 2018 the Ultimaker S5 launched with a new filament flow sensor.

To make this sensor work:

The firmware team took care of basic implementation

The Ultimaker Cura team corrected the 3D printer profile to take the flow sensor signal into account

The materials team tested the software correction for every material variation

After adjusting for feedback, a new version of Ultimaker Cura was released and users could enjoy a higher-quality and more reliable 3D printing experience

But, users of other 3D printers can’t take advantage of all this development and testing. With any new version of Ultimaker Cura, they will experience quality-of-life improvements, but these only minimally affect print quality.

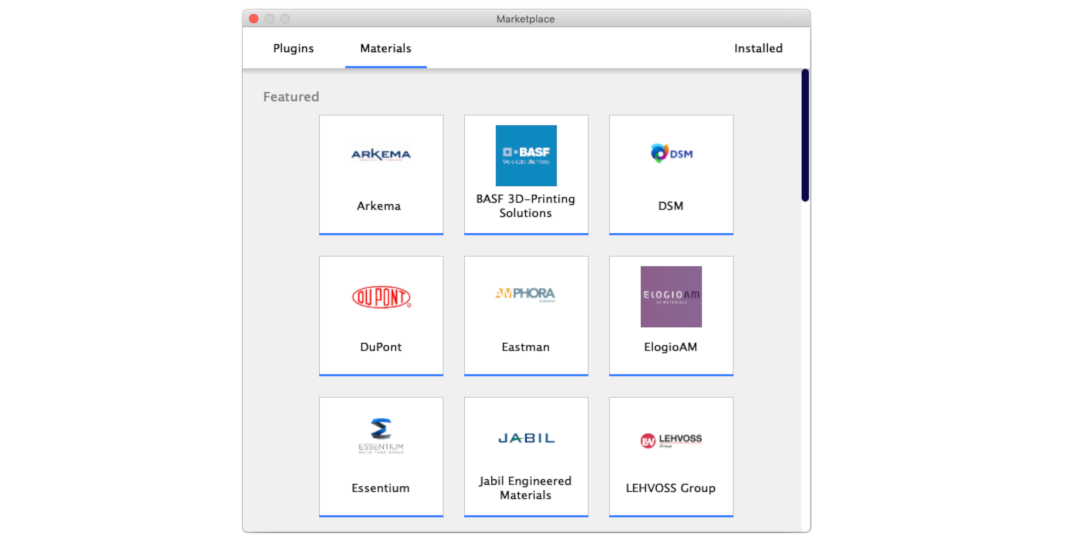

Fully leverage the Ultimaker Marketplace

If your question is "how can I easily print with more materials?" Our answer is the Ultimaker Marketplace. Better than an open filament system, this library of preconfigured print profiles is made for Ultimaker 3D printers.

Here, you’ll find an ever-growing list of global brands that have developed their own print profiles. These make their materials work with Ultimaker hardware as easily and reliably as Ultimaker filament.

Ultimaker Marketplace lets you download a library of print profiles for advanced polymers. These are created by global brands for use with Ultimaker 3D printers

The extra features that transform your workflow

Many other integrated features work together to create a hassle-free 3D printing experience, giving you higher uptime and an increased ROI.

For example, owners of the Ultimaker 3, Ultimaker S3, Ultimaker S5, and the Ultimaker S5 Pro Bundle benefit from the following:

NFC spool and print core recognition tells Ultimaker Cura which filament and print core are loaded to increase your workflow efficiency

Network monitoring via Ultimaker Digital Factory lets you monitor, start, queue, reorder, and duplicate print jobs all from your desk

Remote monitoring via an Ultimaker Account gives you the same control of your 3D printer from anywhere in the world

Customer support is better. If you’re using an Ultimaker, you automatically benefit from full Ultimaker Cura support – in your own language and timezone

And many more...

Conclusion: Make the most of your time

Your time is worth money. If you want the best 3D print results using Ultimaker Cura with minimal hassle, then it makes sense to print your parts and models with an Ultimaker 3D printer.

Each machine has thousands of hours of tweaking, testing, and optimization built-in. And the same R&D investment is found across all Ultimaker hardware, software, and materials.

Combined together, these products give you access to one of the most seamless, reliable, and open 3D printing experiences available today.

Ready to upgrade your Ultimaker Cura experience?