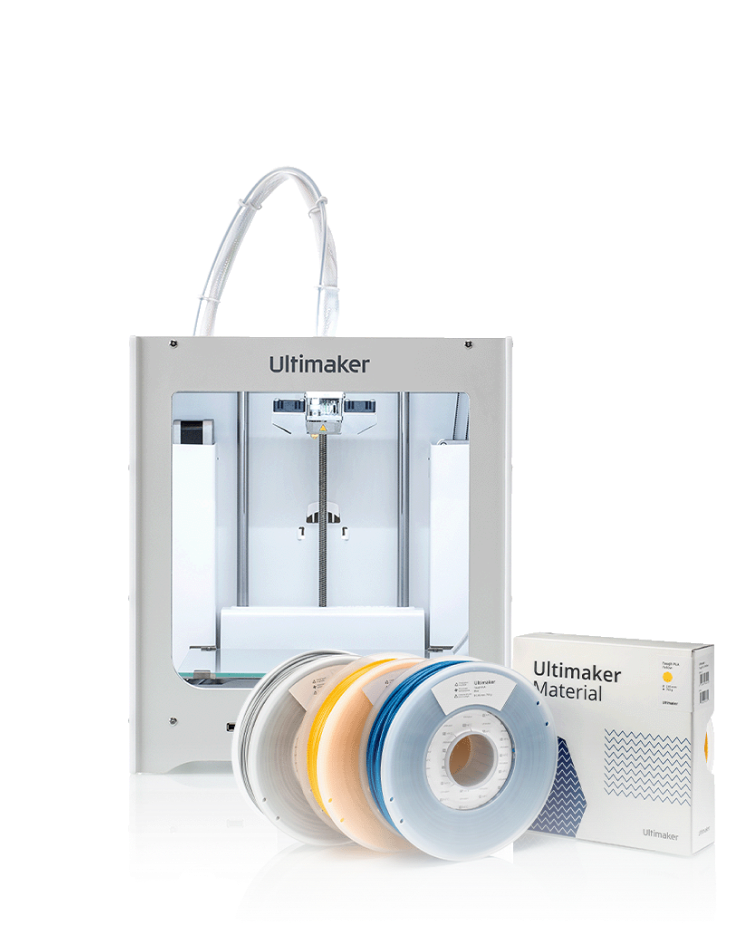

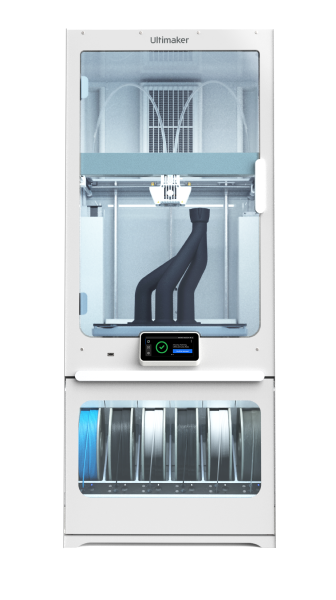

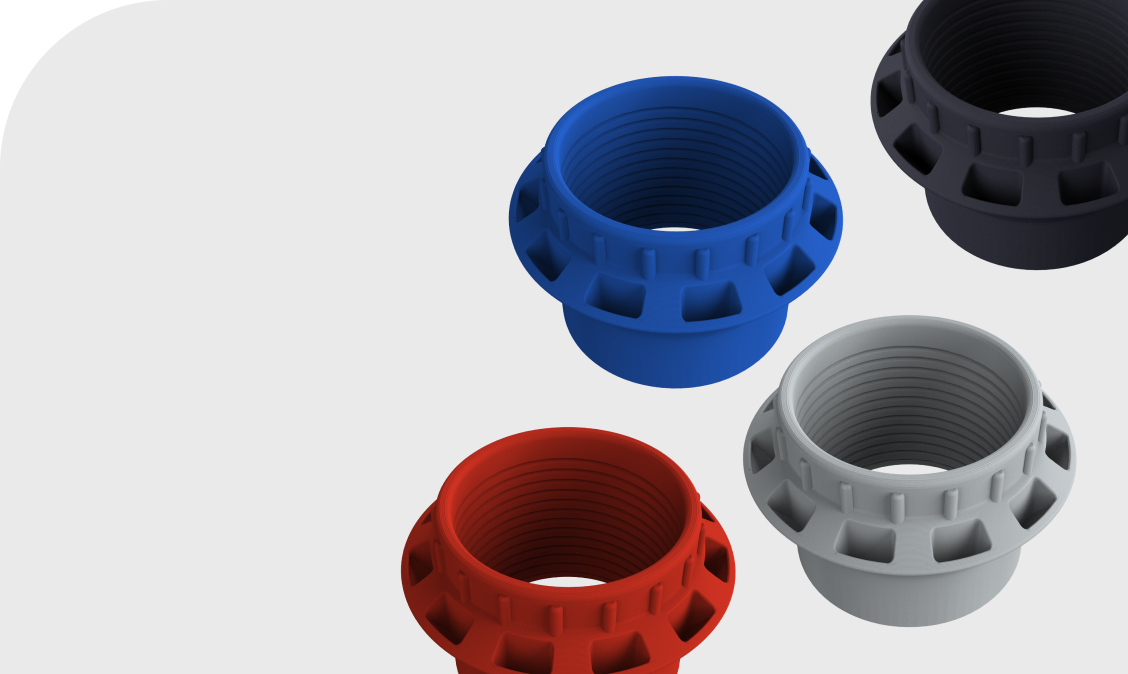

Widest material choice on the market

The UltiMaker 2+ Connect is compatible with materials for a wide range of applications. Simply "click and 3D print" using tested profiles on the Marketplace. And explore endless new application opportunities.

Compatible with

20+

materials