Combining 3D printing with traditional metal casting

While metal 3D printing offers numerous advantages, traditional metal casting remains a crucial manufacturing process, especially for high-volume production. Interestingly, these two technologies can be combined to leverage the strengths of both, creating innovative solutions for complex manufacturing challenges.

3D printed patterns for investment casting

Investment casting, also known as lost-wax casting, is a traditional method for producing highly detailed metal parts. By incorporating 3D printing into this process, manufacturers can achieve several benefits:

- Complex geometries: 3D printed patterns can achieve intricate designs that would be difficult or impossible to create with traditional pattern-making methods.

- Rapid prototyping: 3D printing allows for quick iteration of pattern designs, speeding up the development process.

- Cost-effective low-volume production: For small production runs, 3D printed patterns can be more economical than traditional tooling.

- Design flexibility: Changes to part designs can be implemented quickly without the need for new tooling.

Process steps for 3D printed investment casting

- Create a 3D CAD model of the desired part.

- 3D print the pattern using a material suitable for burnout (often a specialized resin or wax-like material).

- Attach the printed pattern to a wax sprue system.

- Dip the assembly in ceramic slurry and coat with stucco to create a shell.

- Allow the ceramic shell to dry and harden.

- Heat the mold to melt out the 3D printed pattern (burnout process).

- Pour molten metal into the ceramic mold.

- Once cooled, break away the ceramic shell to reveal the cast part.

- Perform any necessary finishing operations.

3D printed sand molds for sand casting

Sand casting is another traditional method that can benefit from 3D printing technology. By directly 3D printing sand molds, manufacturers can:

- Eliminate the need for pattern making, reducing lead times and costs for low-volume production.

- Create complex internal geometries that would be difficult to achieve with traditional molding techniques.

- Easily incorporate features like cores and cavities into the mold design.

- Rapidly iterate mold designs for prototyping and testing.

Benefits of combining 3D printing and casting

- Scalability: Transition from prototyping to mass production using the same initial design.

- Material options: Access a wider range of metals and alloys compared to direct metal 3D printing.

- Large part production: Cast parts can be significantly larger than the build volume of most metal 3D printers.

- Cost-effectiveness: For certain geometries and production volumes, this hybrid approach can be more economical than either method alone.

- Familiar processes: Leverage existing casting expertise while incorporating advanced design capabilities.

Considerations and challenges

While combining 3D printing with casting offers many advantages, there are some factors to consider:

- The burnout process for 3D printed patterns may require different parameters compared to traditional wax patterns.

- Some 3D printing materials may leave more residue during burnout, potentially affecting cast part quality.

- Design guidelines for 3D printing and casting must both be considered, which may require specialized expertise.

- Initial setup costs for implementing 3D printing in a casting workflow can be significant.

By thoughtfully combining 3D printing with traditional casting methods, manufacturers can create a powerful hybrid approach that maximizes the benefits of both technologies. This synergy allows for greater design freedom, faster prototyping, and more flexible production strategies.

As we look to the future, it's clear that the integration of advanced technologies like 3D printing with traditional manufacturing methods will continue to evolve, opening up new possibilities for innovation in metal part production.

Future trends in metal 3D printing

The field of metal 3D printing is rapidly evolving, with new technologies, materials, and applications emerging regularly. As we look to the future, several key trends are shaping the landscape of metal additive manufacturing:

Advancements in printing technologies

- Multi-material printing: Development of systems capable of printing parts with multiple metals or metal-polymer combinations in a single build.

- Faster print speeds: Innovations like multi-laser systems and advanced scanning strategies are significantly reducing build times.

- Larger build volumes: New printers are pushing the boundaries of part size, enabling the production of larger components.

- In-situ monitoring and correction: Advanced sensors and machine learning algorithms are improving print quality and consistency by detecting and correcting issues in real-time.

- Hybrid manufacturing: Integration of additive and subtractive processes in a single machine for streamlined production.

New materials and alloys

The range of printable metals continues to expand, with several exciting developments:

- High-performance alloys: Development of new superalloys and intermetallics specifically designed for additive manufacturing.

- Functionally graded materials: Creating parts with varying material properties throughout their structure.

- Nanomaterials: Incorporation of nanoparticles to enhance material properties like strength or conductivity.

- Refractory metals: Improved processes for printing challenging materials like tungsten and molybdenum.

Software and design tools

Advancements in software are crucial for realizing the full potential of metal 3D printing:

- Generative design: AI-powered tools that can automatically create optimized part designs for additive manufacturing.

- Simulation and prediction: More accurate modeling of the printing process to predict and mitigate issues like thermal distortion.

- Topology optimization: Advanced algorithms for creating lightweight yet strong structures.

- Digital twins: Creating virtual representations of parts and processes for improved quality control and predictive maintenance.

Industrialization and standardization

As metal 3D printing matures, we're seeing increased focus on:

- Automation: Development of fully automated production lines incorporating 3D printing, post-processing, and quality control.

- Standards development: Creation and adoption of industry-wide standards for materials, processes, and quality assurance.

- Certification processes: Streamlined methods for certifying 3D printed parts for critical applications in aerospace, medical, and other regulated industries.

- Supply chain integration: Incorporation of metal 3D printing into broader digital manufacturing ecosystems.

Emerging applications

New use cases for metal 3D printing continue to emerge across various industries:

- Microstructure control: Precise control over material microstructure to achieve specific properties.

- 4D printing: Creating metal parts that can change shape or properties in response to environmental stimuli.

- In-space manufacturing: Development of metal 3D printing systems for use in zero-gravity environments.

- Biomedical implants: Customized, biocompatible implants with engineered porosity for better integration with living tissue.

- Energy storage: 3D printed electrodes and other components for advanced batteries and fuel cells.

Sustainability focus

Environmental considerations are becoming increasingly important in metal 3D printing:

- Energy efficiency: Development of more energy-efficient printing processes and machines.

- Material recycling: Improved methods for recycling metal powders and failed prints.

- Lifecycle analysis: Better understanding and optimization of the environmental impact of metal 3D printed parts throughout their lifecycle.

As these trends continue to develop, we can expect metal 3D printing to play an increasingly central role in manufacturing across a wide range of industries. The technology's ability to create complex, customized parts with improved performance characteristics will likely lead to new design paradigms and manufacturing strategies.

However, realizing the full potential of these advancements will require ongoing collaboration between researchers, equipment manufacturers, material scientists, and end-users. As the field evolves, staying informed about these trends and their potential impacts will be crucial for businesses looking to leverage metal 3D printing effectively.

Conclusion: The evolving landscape of metal 3D printing

As we've explored throughout this article, metal 3D printing is a transformative technology that continues to reshape manufacturing across numerous industries. From its ability to create complex geometries to its potential for on-demand production, metal additive manufacturing offers unique advantages that are driving innovation and efficiency.

Key takeaways include:

- The diverse range of metal 3D printing technologies, each with its own strengths and applications

- The expanding selection of printable metals and alloys, enabling new possibilities in part design and performance

- The critical role of post-processing in achieving desired part properties

- The potential for combining 3D printing with traditional manufacturing methods for optimal results

- The exciting future trends that promise to further advance the capabilities of metal 3D printing

As the technology continues to mature, we can expect to see:

- Increased adoption across industries, particularly in aerospace, automotive, medical, and energy sectors

- Further improvements in print speed, accuracy, and material properties

- More seamless integration of metal 3D printing into broader digital manufacturing ecosystems

- Development of new design paradigms that fully leverage the unique capabilities of additive manufacturing

- Greater focus on sustainability and lifecycle considerations in metal 3D printing processes

For businesses and professionals looking to leverage metal 3D printing, it's crucial to stay informed about these developments and to carefully consider how the technology aligns with specific manufacturing needs and goals. While metal 3D printing offers tremendous potential, successful implementation requires a thorough understanding of its capabilities, limitations, and best practices.

As we look to the future, it's clear that metal 3D printing will play an increasingly important role in shaping the manufacturing landscape. By enabling the production of parts that were previously impossible or impractical to create, this technology is opening up new frontiers in design and engineering. The ongoing advancements in materials, processes, and applications promise to make metal 3D printing an even more powerful tool for innovation and production in the years to come.

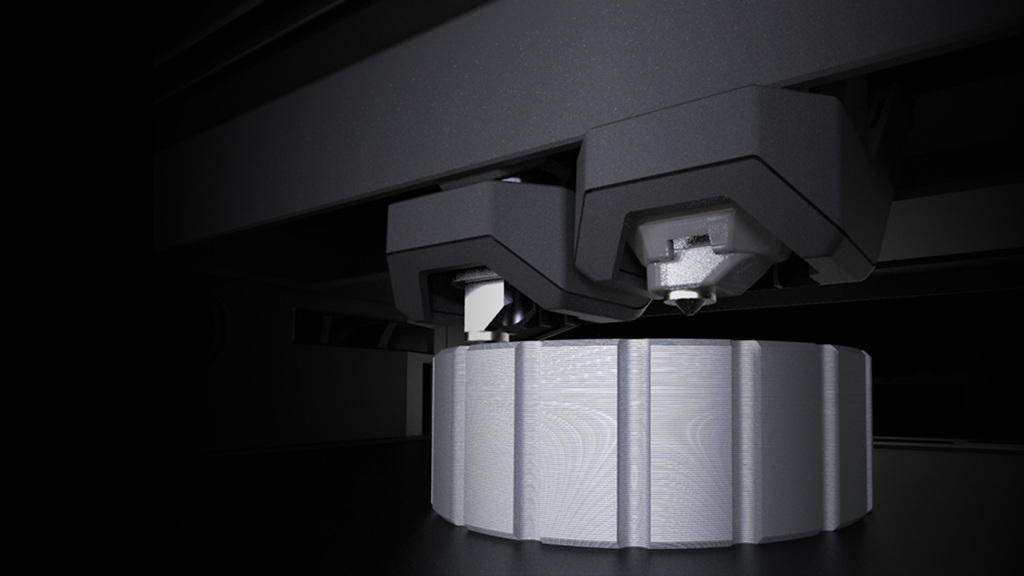

If you are looking to print durable parts to replace metal, UltiMaker might have the solution. With UltiMaker printers, such as the Factor 4 and the new UltiMaker S8, you can print durable pieces with materials such as Nylon CF Slide to replace metal.