Průmyslová keramika is one of central Europe’s leading suppliers of ceramic mixes and custom heat-resistant parts. The Czech company switched from traditional production methods in 2016 and began creating mold inserts using Ultimaker 3D printers. This meant that refractory mold cores could be manufactured five times faster, at 10% of the cost, and with perfect repeatability.

Průmyslová keramika which translates to “industrial ceramics” was founded in 1991. Its 75 employees now produce over 9,500 tons of ceramic mixes and almost 1,600 tons of shaped pieces each year – with an annual turnover of 220 million Czech crowns ($9.8 million USD).

The company’s success lies in its agile response to customer requirements. Each order for a ceramic part is unique, requiring a unique mold design. And it was this demand for constant customization that led their production team to consider additive manufacturing technology.

Accurate, bespoke industrial manufacturing

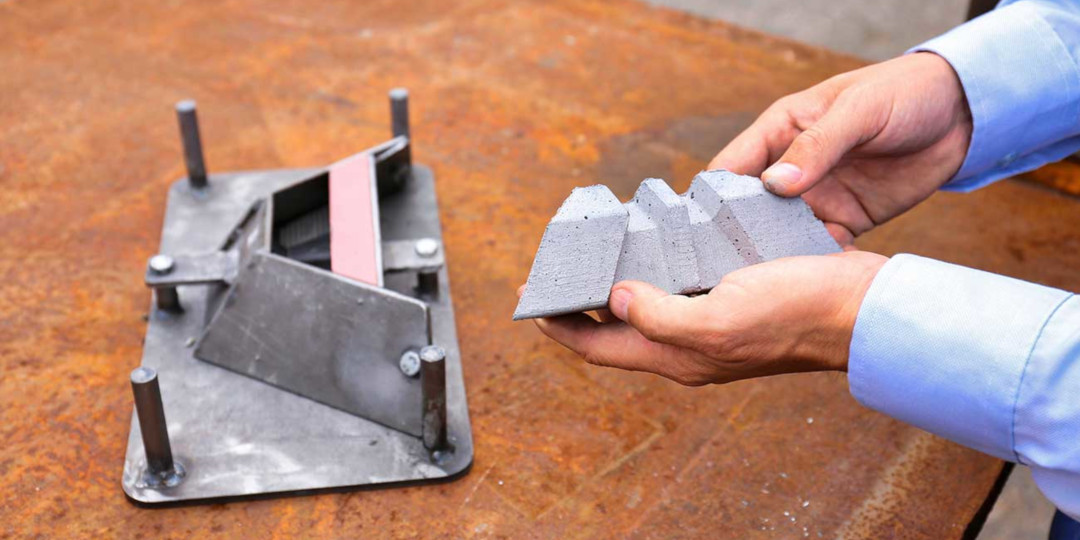

Molds are commonly created with a steel shell, which forms the outer shape. Core inserts then define important internal and functional details, like grooves, holes, and curves. These fittings are often complex shapes, which must be designed and manufactured to precise customer specifications. In the past, such internal shapes were created using wood or metal inserts. But these required manual carpentry or CNC machining – processes which were time consuming and expensive. For example, one wooden insert could cost up to 20,000 Czech crowns ($895 USD), and take more than 30 hours to carve.

The finished product: A ceramic refractory part created with a steel mold shell and 3D printed mold core

During 2013, the management team piloted a 3D printing project in an effort to accelerate mold production, but they ran into trouble with their first 3D printer. "We were struggling with extreme printer misbehavior”, says Jakub Cvilinek, Průmyslová keramika’s Managing Director. “Only about 30% of the prints were successful, the rest was waste. Even after this experience, we believed in 3D printing. It was a great school for us. The technology was still good for us – we just chose the wrong printer."

Reinventing the mold-making workflow with Ultimaker 3D printers

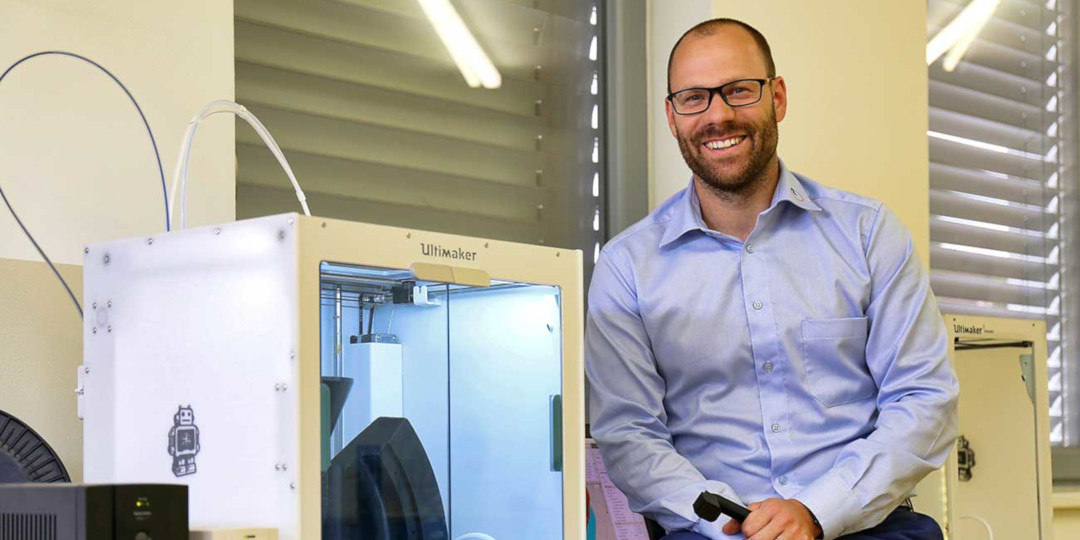

In 2016, Průmyslová keramika chose what turned out to be the right 3D printer: an Ultimaker 3 Extended. Finally, the company had found a reliable and professional 3D printing solution. Two years later, Jakub Cvilinek added a new Ultimaker S5 to their toolkit, delivering the same print quality, but with a bigger build volume behind an easier user interface.

As the team took advantage of 3D printing to make cores and mold inserts, the technology’s benefits emerged: accurate, fast, and repeatable production – coupled with almost complete creative freedom in designing parts. Best of all, the solution was significantly cheaper than previous processes.

Managing Director, Jakub Cvilinek next to the Ultimaker S5, which allows faster, more affordable, and repeatable mold core manufacture

For 3D printing mold cores, Průmyslová keramika use only PLA material because of its ease of use and low glass-transition temperature. This is because many of the core parts and inserts remain embedded in the ceramic material until it is fired. At more than 900 °C, the PLA is then easily and completely removed from the mold.

The company employs two operators who oversee the 3D printing of production parts, which are designed by their engineering department, using Autodesk Inventor and AutoCAD.

3D printing accelerates and facilitates production

"The Ultimaker 3 Extended and S5 have brought us substantial savings and acceleration of production, as well as the ability to produce shapes that were previously impossible,” recalls Jakub Cvilinek.

In Průmyslová keramika, 3D printing has proven to be a great asset for the manufacturing process. Required parts can now be manufactured roughly up to five times faster and ten times more cheaply than using traditional processes. For example, the material used to 3D print a mold core for an air and gas mixer in an industrial burner costs only 300 Czech crowns ($13.43 USD). This meant that it only took a few months for the ceramics specialist to achieve ROI against the Ultimaker 3D printers’ initial purchase cost.

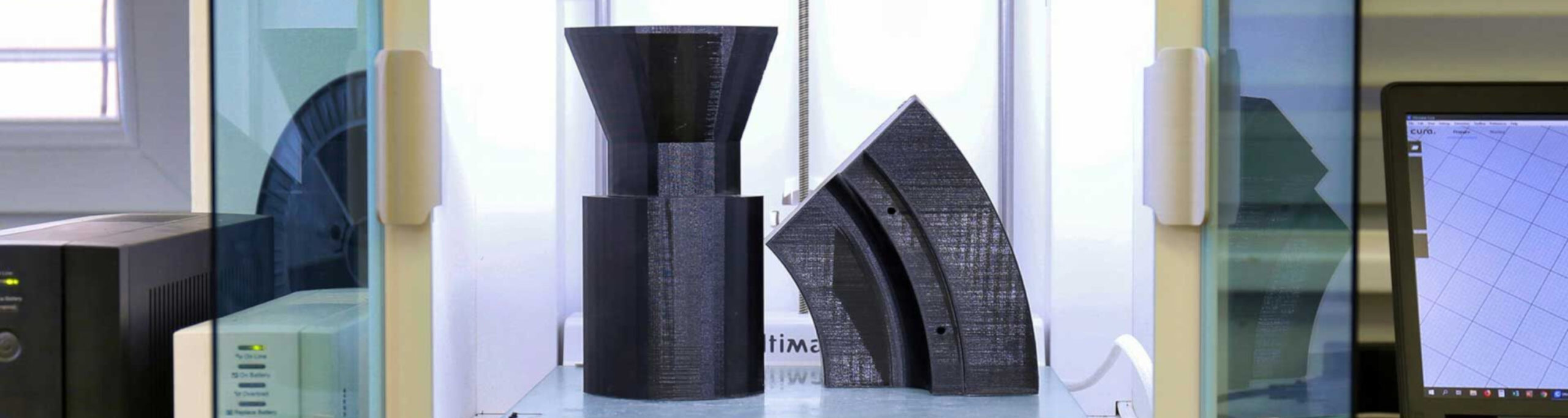

3D printed mold inserts offer greater design freedom to even make demolding easier

With reduced dependence on a CNC-milling machine, the company also saved on the cost of employment. It now benefits from on-site production, fast prototyping, high uptime, and (whenever necessary) repeatable production.

Conclusion: 3D printing offers a new level of design freedom

For Průmyslová keramika, the addition of the Ultimaker 3 and Ultimaker S5 has transformed their custom-manufacturing workflow. They now have confidence in their ability to produce parts that meet or exceed their customers’ demands. Jakub Cvilinek adds:

Some particularly complex mold core shapes for refractories were either not manufacturable or too costly by traditional methods. Thanks to 3D printing we can prepare them ourselves.

Could your production processes benefit from Ultimaker 3D printers? Learn more about the Ultimaker S5.

This story was originally published here, and was translated and edited with permission.