Shrinking prototype and design costs from $200 to $4 per component

In a matter of minutes to hours, we can have an idea printed and ready for client presentations—much faster than machining or using a third-party source. Lead time to present ideas is dramatically decreased with Ultimaker and provides more control.

- Brian Hagar, Outside Sales, Hartfiel Automation

Challenge and solution

Challenge

Hartfiel Automation needed a solution for prototyping products that they could test and showcase during customer meetings. Outsourcing designs to machine their products would cost them an average of $125 per component, and would take 1 to 2 weeks to complete with an external supplier. As they estimated that it would cost an average of $3,500 to machine their products without prototyping, the Hartfiel Automation team began searching for a cost-efficient way to iterate and test components.

Solution

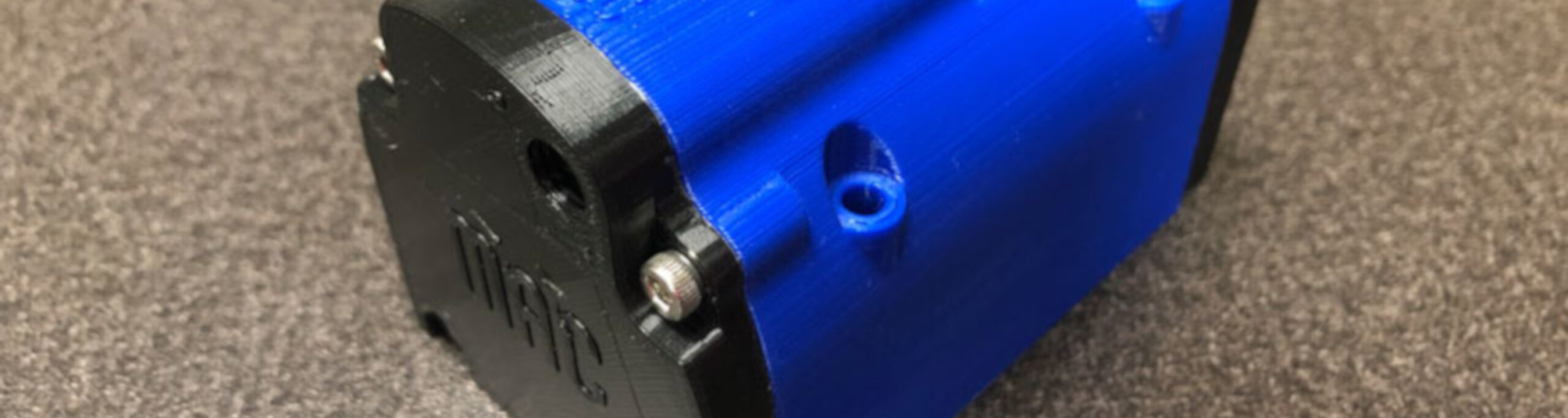

In an effort to solve customer pain points and utilize unique return on investment tools, the Hartfiel Automation team discovered 3D printing as an affordable solution to prototyping needs. After adding two Ultimaker 2 Extended+ 3D printers to their workflow, they were able to bring their prototyping costs down from an average of $125 to an average of $4 per component. In addition to saving money, they drastically reduced the time spent creating their component designs from days to mere hours.

Cost comparison

Hartfiel Automation is able to 3D print prototypes and designs for client presentations in a matter of hours, while saving money in the process.