Deployability is becoming a central focus for additive manufacturing: the ability to set up and operate 3D printing capabilities wherever they deliver the most value.

Additive manufacturing is no longer limited to specialized labs or centralized workshops. Defense teams are increasingly adopting deployable 3D printing to bring production closer to where it’s needed - reducing logistics dependencies, enabling faster repairs, and supporting a wide range of maintenance, repair, and overhaul (MRO) operations.

Why deployability matters for defense

Defense infrastructure is spread across locations: bases, hangars, and depots worldwide. Moving equipment, parts, and technical capabilities between these facilities is a complex and costly process. Deployable 3D printing changes this through:

-

Localized production of spare parts in maintenance halls or at regional bases.

-

Faster turnaround times for MRO teams working under tight schedules.

-

Reduced dependence on supply chains, especially for legacy or low-volume parts.

-

Adaptability, with systems that can move from R&D labs to operational sites without disruption.

Deployability enables consistent manufacturing results in different environments, without requiring extensive setup or specialized infrastructure.

The challenges of deployment

Operating additive manufacturing outside of controlled lab environments introduces new considerations:

-

Mobility and footprint: Systems must be compact, modular, and easy to move between facilities.

-

Ease of setup: Technicians should be able to install and operate machines quickly in different locations.

-

Environmental resilience: Printers must perform reliably despite dust, vibrations - or any other changing environment, whether it's on a ship or in a workshop.

-

Operator-friendly workflows: Intuitive interfaces make it easier for a broad range of staff to use the technology effectively.

Without deployability, additive manufacturing might be confined to a handful of centralized sites - limiting its impact.

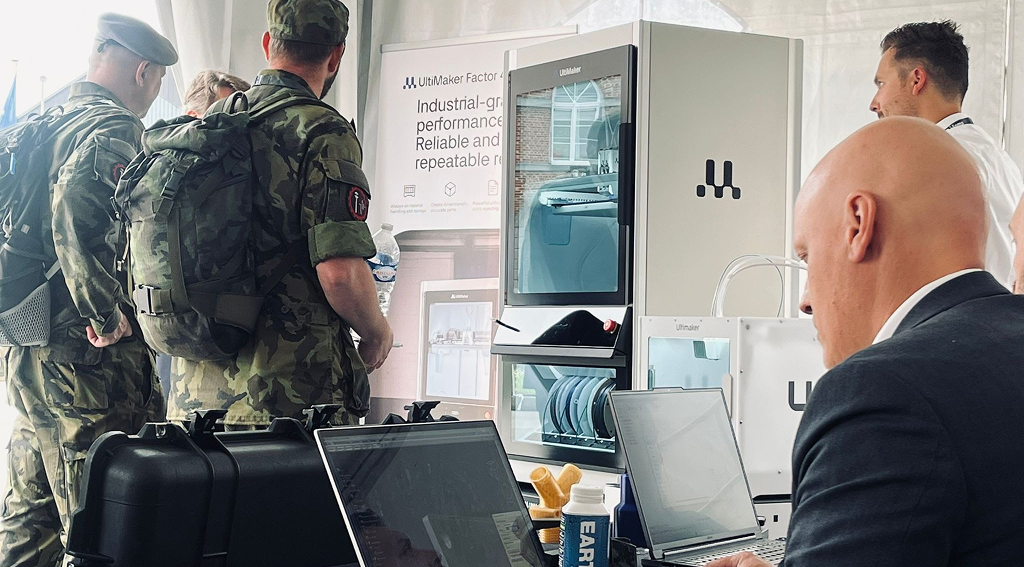

UltiMaker: Built for deployability

UltiMaker’s 3D printers combine professional-grade performance with a user-friendly design - making them well-suited for defense environments where flexibility is critical.

For defense applications, UltiMaker’s deployable advantages include:

-

Compact, modular systems that can be transported easily between maintenance halls, bases, or labs

-

Quick setup and intuitive workflows, reducing reliance on specialist operators.

-

Compatibility with a broad range of engineering materials for functional, wear-resistant parts.

-

NATO-aligned and European-manufactured systems, supporting defense procurement standards and supply chain transparency.

This combination allows defense teams to integrate 3D printing into diverse settings, maximizing efficiency and minimizing downtime, from helicopter halls and shipyards to logistics centers and research facilities.

UltiMaker’s deployable ecosystems help ensure additive manufacturing is not limited to a single site, but becomes a distributed capability across the defense sector. By making 3D printing portable, accessible, and dependable, UltiMaker helps defense teams unlock new levels of adaptability and resilience.