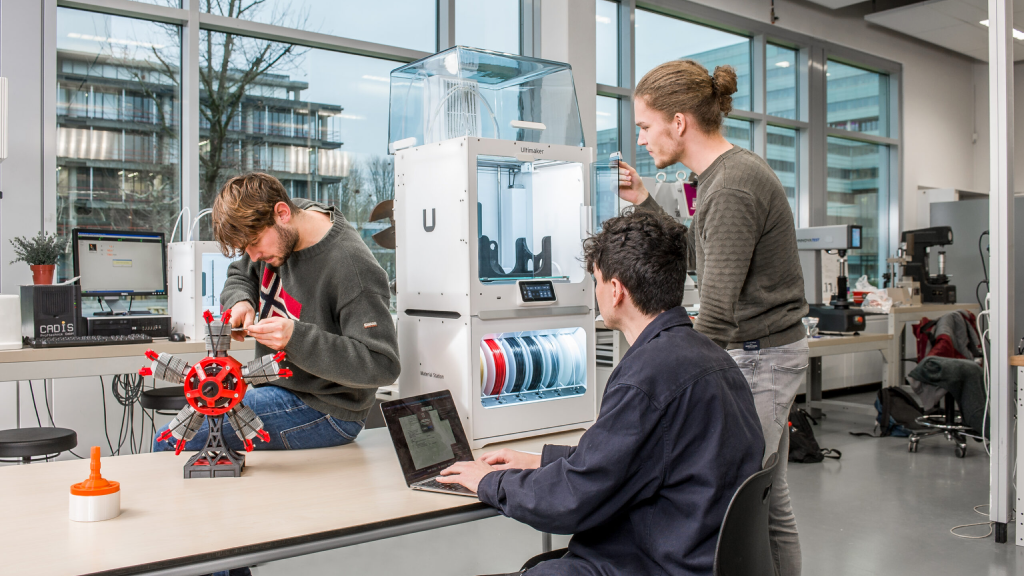

Education currently faces unique challenges when preparing students for the practical demands of today’s industries. While traditional learning focuses on theory, modern careers require hands-on problem-solving and technological literacy.

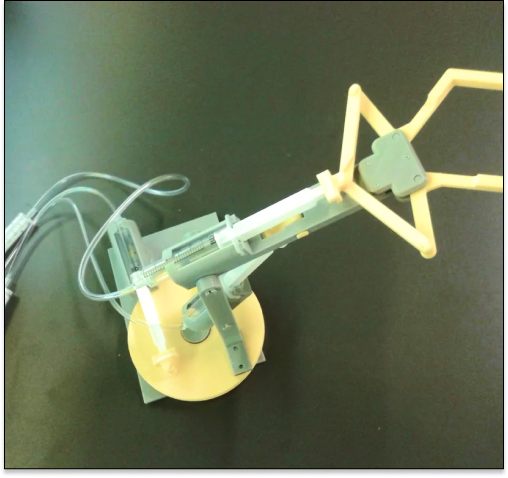

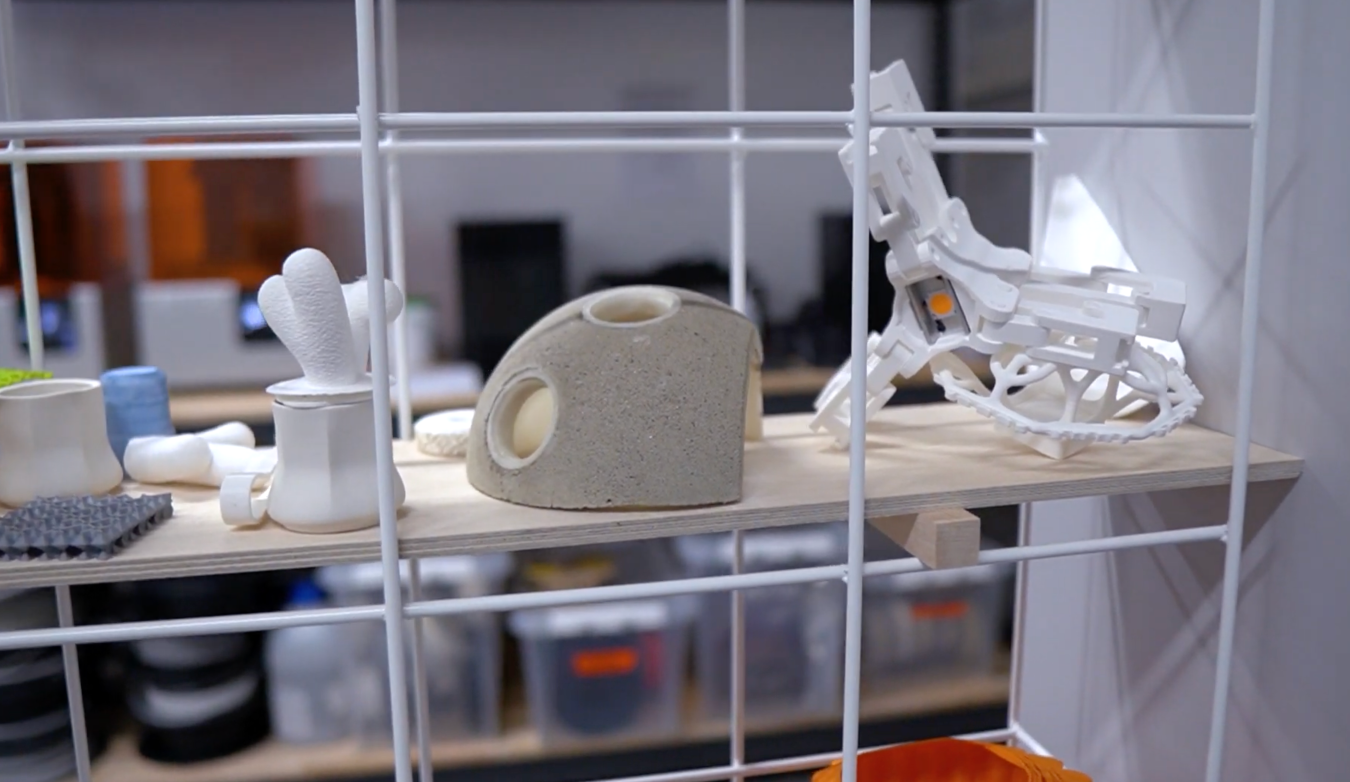

3D printing can help bridge this divide by making the learning process more tangible by helping students grasp abstract concepts, develop critical thinking, and explore through trial and error how they can apply their knowledge in real-world scenarios.

This article will examine how 3D printing can be integrated across different levels of education and how it helps equip students with essential skills for their future workplace.

3D printing in primary education

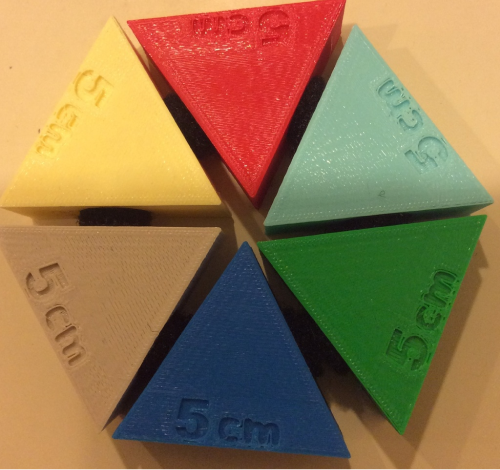

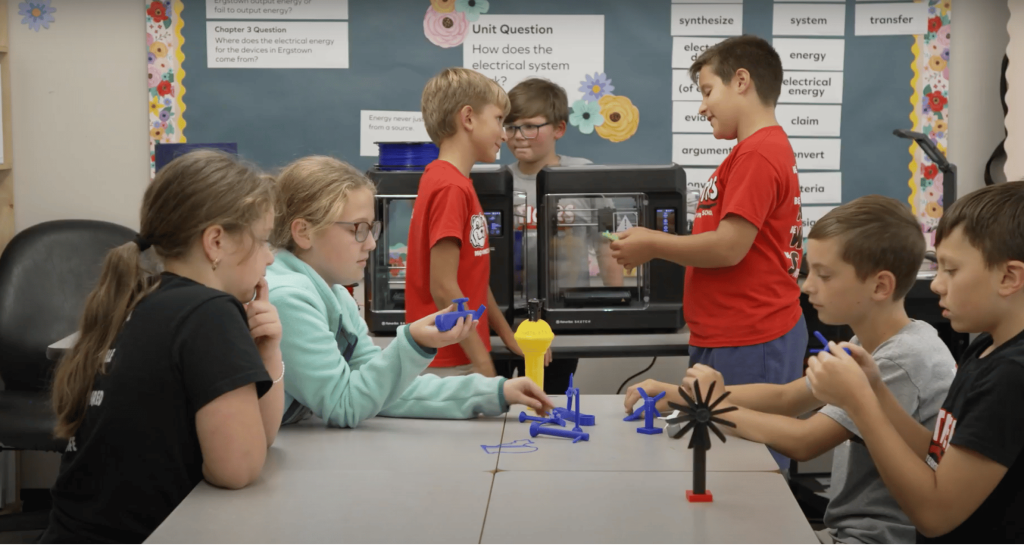

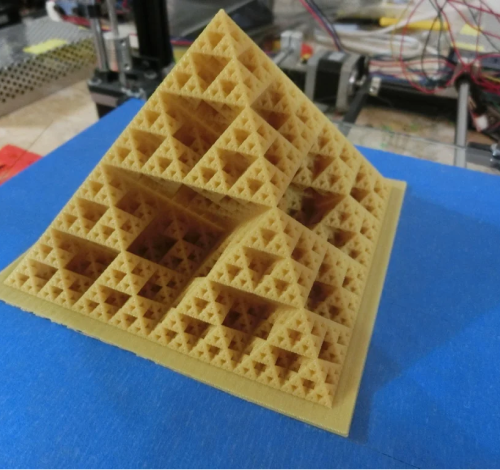

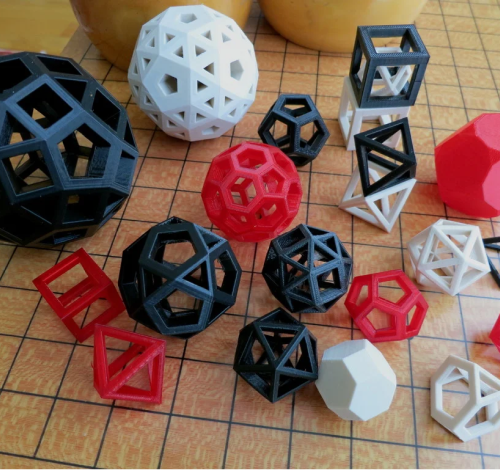

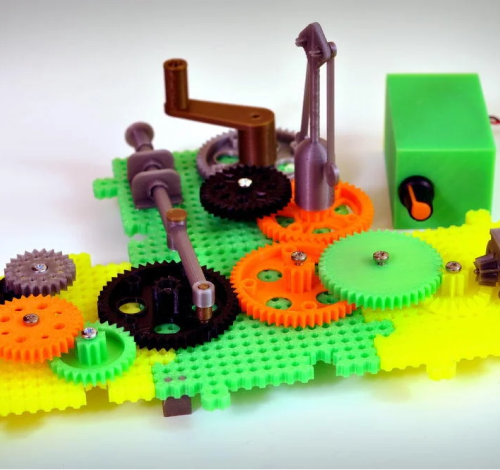

In primary education 3D printing can serve as a dynamic tool to teach a multitude of subjects, for example in mathematics students can design and print geometric shapes aiding in the understanding of spatial relationships and complex concepts.

We’ll go over each of the main subjects that can leverage 3D printing as a learning tool and see how both teachers and pupils can benefit from the technology.

Learning the basics

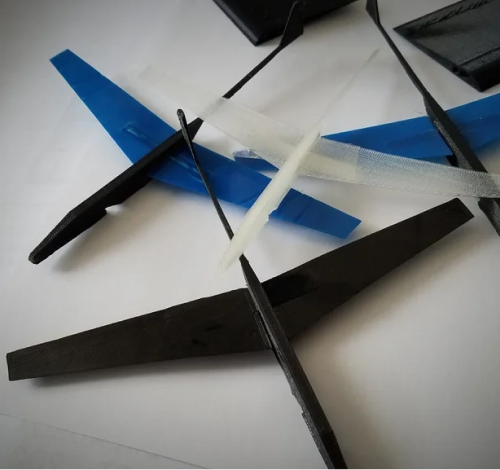

We can break down the 3D printing process into 3 main steps: designing/modeling, slicing and 3D printing. Initially, students can learn to transform 2D drawings into 3D objects by printing them and help them get accustomed to the various softwares involved in the process.

1. Designing

Pupils can either search for and download existing models on online STl repositories like Thingiverse or use software options like 3D Slash or Tinkercad to create their own designs. We recommend visting the Thingiverse education section for a large variety of designs grouped by curriculum (including lessons) along with various training courses for educators.

2. Slicing

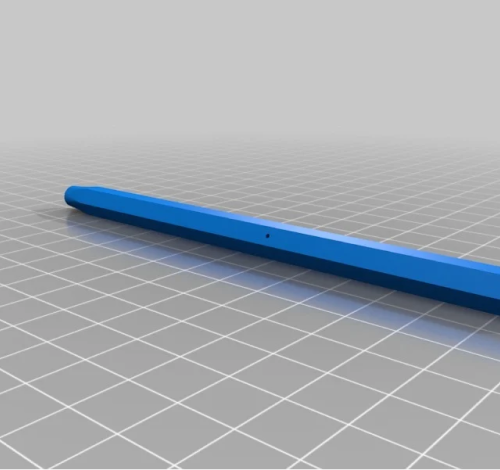

Since 3D printers work by depositing materials in layers, students will need to use a slicing software like Cura to import their designs, “slice” them, and export them into a format that the 3D printer can use. This process will help students better understand how the 3D printing process works and also allow them to explore and tinker with their designs by changing various printing parameters.

3. Printing

In the final part of the process students can see in real time how the 3D printing process works. With the most common 3D printing technology, FDM (Fused Deposition Modeling) it is easy to understand how the various parts of the machine work to extrude the filament into layers building up towards the finalized part.

While there is a wide range of materials available, we recommend PLA (poly-lactic acid) as the best printing material for this purpose as it’s low cost, and easy to use.