3D printing is changing the face of architectural design, both inside and out. Traditional 2D graphics are a vital part of the design process; however, a tangible 3D model does not only clarifies the details of the space but also ensures the client fully understands how the end product will look.

Old meets new

The process of design is rooted in knowing how to put pen to paper. Through sketching out ideas, architectural designers can explain design concepts to clients, creating an image that also inspires further innovation.

However, creating realistic models of architectural designs is more of a challenge. ‘Fly-throughs’ and 3D renderings convey some of the design’s beauty and functionality, but they can only go so far. A physical model showcases exactly what a design will look like – which is where 3D printing comes in.

3D printing and landscape design

Kurt Kraisinger is one designer who is harnessing the power of 3D printing. For over 20 years, he’s been providing design and consultancy services for various planning and landscape architecture projects in the US. Together with his team, he is transforming outdoor spaces into memorable locations that allow people to fully engage in their surroundings, whilst making a positive impact on the environment. Over the years, he’s worked on private residences, corporate campuses, commercial retail centers, entertainment areas and more. Kurt explains how 3D printing has helped his design practices, and how it fits into his daily activities.

The design process

Initially, Kurt and his team create hand renderings – initial brainstorming sketches that help them develop ideas. Then, they create a formal ‘sketch plan’, which is still freehand, but features greater detail. This helps the team to establish the direction of the project, and how their ideas might work in reality.

“During this phase,” Kurt explains, “we're already thinking about the major facets of the project: how the work will harmonize with the home's architecture, how the traffic will flow and different areas will function. We're also considering the drainage, elevations and the major features, such as the pool, spa, patio, hardscape and plantings.”

They then develop a master plan, a detailed version rendered digitally in both overhead and perspective views. However, they don’t use CAD programs at this stage – instead, they’re still working with hand-drawn sketches. They load high-resolution scans into Photoshop, where color is added.

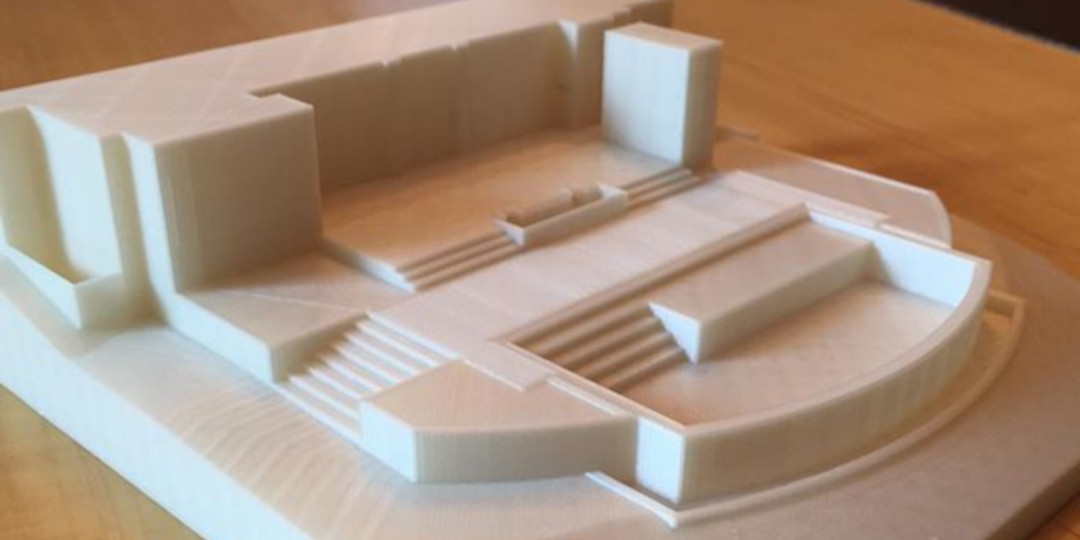

An important part of the design process is sharing the concept with the client. While SketchUp and Pool Studio are both excellent design tools, the renderings can only ever be two dimensional, which limits the client’s ability to envisage the design. 3D printing reveals what the design will look like in a tactile, sculptural way, and it gives clients something tangible that they can show to others.

Kurt says: “I think someday, everyone will have a 3D printer in their home. There will come a time when we’ll be able to send a file to a client, who in turn will be able to make their own 3D model the way you print out a document now.”

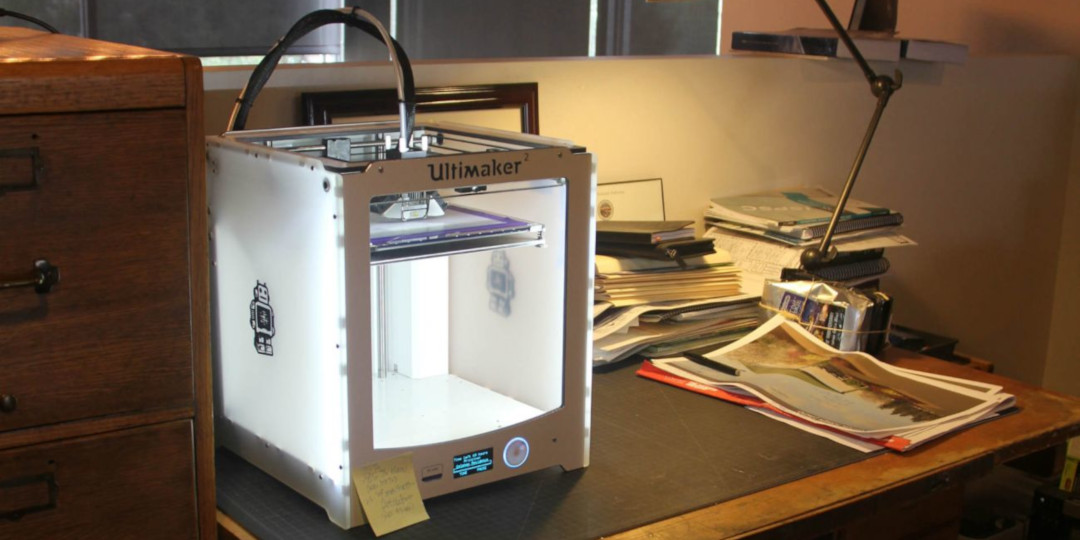

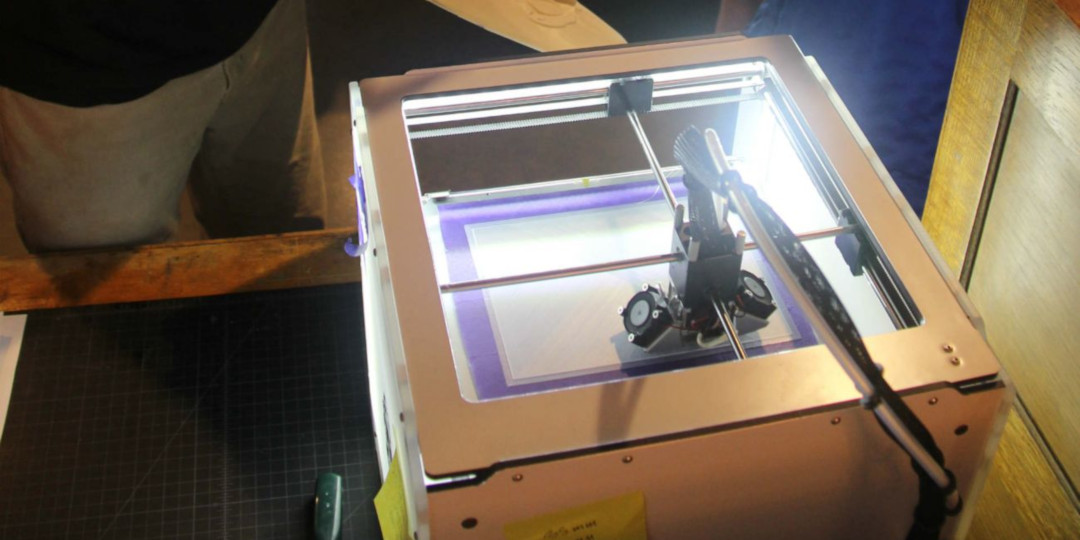

Using an Ultimaker

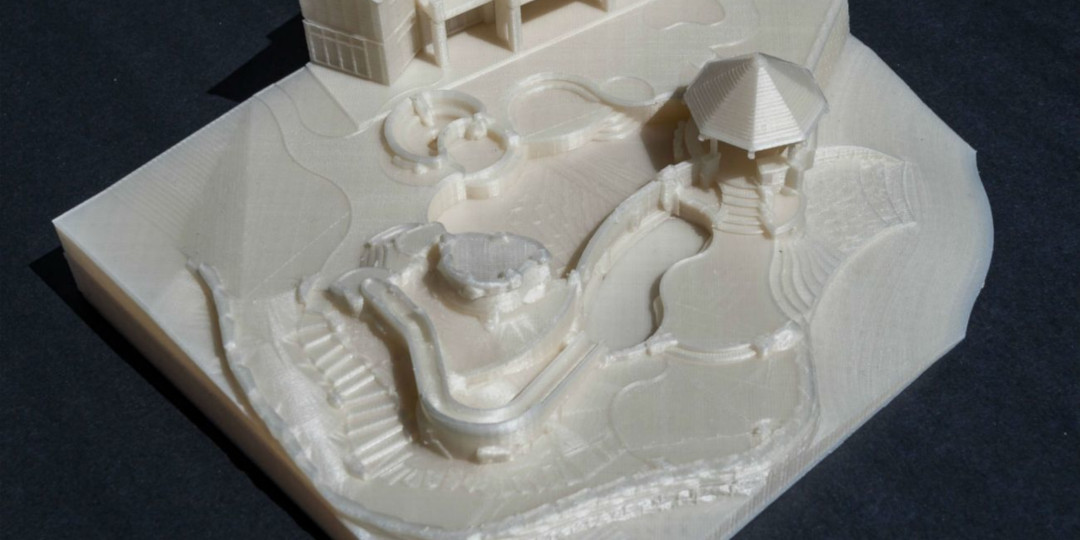

Kurt and his team use an Ultimaker 2, which they find perfect for their needs, as it’s compact, detailed and fairly easy to use. They mostly print using ABS, as it was the best fit for their finished product, and showcased their designs clearly and effectively.

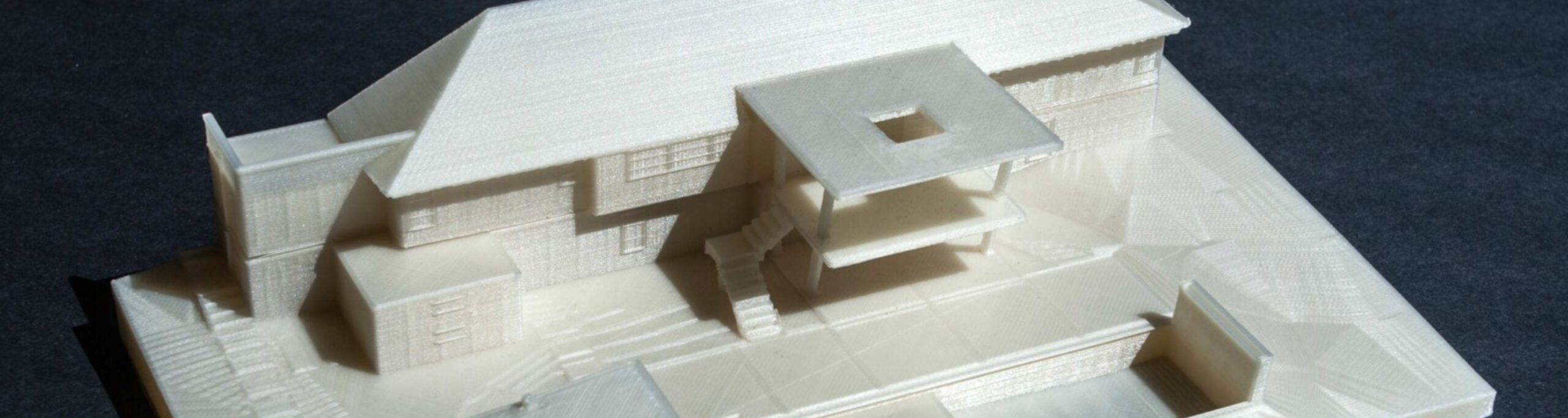

One of their key decisions was to make all their models monochromatic, rather than painting them. They use an off-white material that’s completely absent of any other color. “This is because we don’t want to get locked into a particular color palette,” Kurt explains, “and we don’t want the model to misrepresent the work, should we change directions on color or finish materials.”

The benefits

Having a 3D model helps communicate your vision to clients. It’s a tangible example of how important a comprehensive consulting process is; something some clients want to circumvent to compress the schedule and get things completed faster.

Additionally, having something to touch and feel ensures clients fully grasp the concept, and comprehend what it will look like in reality. Through 3D printed design, architects and clients alike can understand spatial relationships, movement and flow within the property, and how the elevations work together.

“You can look at it from all angles,” Kurt says, “up close or at a distance. And above all, the model can become part of your life.” Indeed, clients often become attached to the models and use them as a point of reference throughout the process. It’s especially useful during construction when things can get chaotic – as it provides clients with a way to stay focused on the end-goal and understand where the project is heading.

The off-white color is reminiscent of a marble statue, which provides the perfect ‘blank canvas’ for clients to imagine their own color palettes on it.

Looking into the future

There will always be a place for traditional rendering in the design process. However, 3D printing lets clients not only see the concept but experience it in a tangible way. They are able to explore the design throughout the design and construction process, and they’re left with a beautiful artifact that they can keep for years after the project is completed. Kurt explains:

3D printed models have become extremely valuable as a design tool. By seeing the spaces in true three-dimensions, issues with elevations, focal points, movement, scale, and proportion become far more apparent than on a flat screen or printed page. We often make corrections both large and small after we've made the model.

Kurt and his team are already thinking of investing in another Ultimaker machine to improve their workflow, proving that in their industry, 3D printing technology is here to stay.