3D printing is becoming increasingly integral in the workplace. It helps companies validate designs, perform functional tests, and bring products to market more quickly. 3D printed prototypes are useful for communicating concepts with stakeholders, resulting in faster iterations and better quality products. Executives seldom need to be convinced of the benefits – yet many continue to outsource their 3D printing tasks; especially when it comes to final part production.

Why companies outsource

Outsourcing means no investment in machinery or training. It also eliminates uncertainty about in-house manufacturing of functional prototypes or final parts. SMEs can’t afford expensive industrial additive manufacturing equipment – outsourcing gives them access to this, and to the right level of expertise, which improves their pipeline efficiency. Even engineering teams in large enterprises haven’t always got the budget to invest in expensive training and equipment.

An alternative solution

Models and prototypes are crucial at the design stage, and companies want quicker, more effective ways to develop their product concepts. Outsourcing lets them use 3D printing technology without a large initial investment; but the throughput times can still be significant, undercutting the short iterations usually associated with 3D printing.

Desktop 3D printers offer a great alternative, without requiring a significant financial investment. They deliver professional results and other benefits; lower costs, quicker lead times, more customer interactions and higher scalability. They’re also easy to operate, resulting in more capacity, more teams, and more departments making use of them. In short, they make 3D printing accessible to more professional users, regardless of industry.

What are your options?

This depends both on purpose and application. Businesses have three options when it comes to 3D printing: outsource the tasks, print in-house with industrial machines, or invest in cost-effective, accessible desktop 3D printers.

The following sections examine the pros and cons of each.

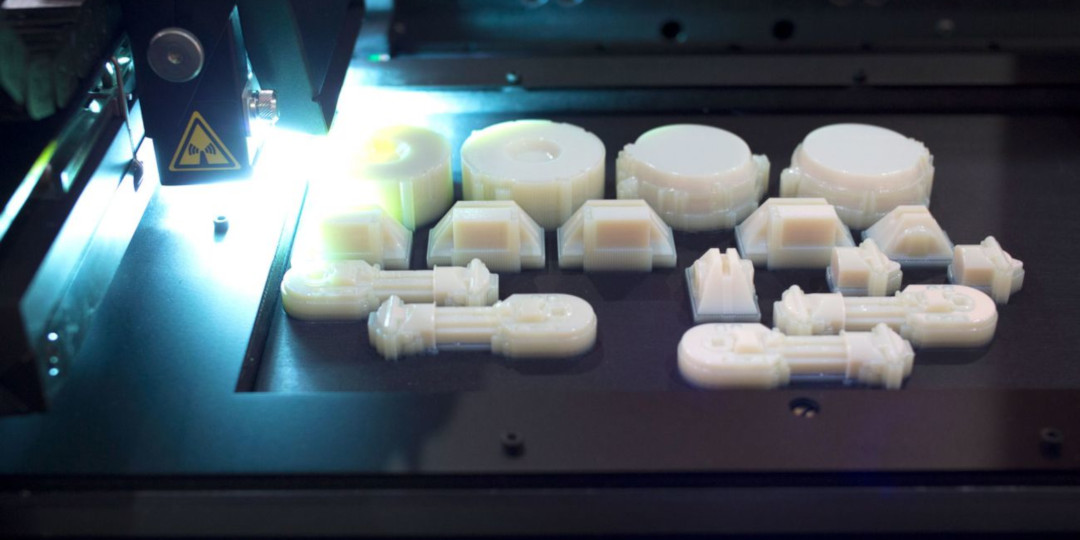

A collection of tools 3D printed in-house and outsourced

Outsourcing to third parties

Outsourcing is a good option if you’re looking for exceptional quality, low quantities, and high complexity. It’s the right choice if you need five parts or fewer per month, especially if the parts are large or require non-standard materials. It’s also useful for final parts that require unusual materials or applications.

However, be warned – this is the slowest, priciest option. Yes, you’ll have an expert performing the task without the associated risks of long-term commitment. But the hourly or project rate is often substantially higher than hiring an employee, and you’ll be waiting longer for them to complete the job.

Pros:

Several technologies available in-house, such as SLA, FFF, and SLS

More materials than an in-house system

Expert knowledge about materials (and their limitations)

No long-term commitment

No initial investment

Cons:

Cost per part is far higher than in-house printing

Slower process - weeks instead of days

More paperwork and more workflow steps. You’ll need to contact suppliers, review quotes, put in a purchase request, pass over specifications, develop ideas, evaluate functionality, and more

Small amendments are expensive

Multiple iterations take longer to create

Customer locked in with software, add-ons, or filaments

Structural underutilization

Inaccessibility. An operator is needed, engineers can’t use it directly, and maintenance means no availability

Not scalable

Parts inside the build chamber of a large industrial 3D printer

In-house industrial 3D printers

Industrial printers are ideal if you’re producing large batches of parts. You’ll need to use the printers frequently to justify the considerable investment and training involved.

Pros:

Wide range of high-performance materials available

When implemented, it’s quicker than using third-party service bureaus

Cost-effective option (when printing in large batches)

Cons:

Significant up-front investment. Expect to pay between $250,000 and $1 million for a comprehensive manufacturing system

Lots of space required. True manufacturing systems require over 30m2 of floor space, industrial HVAC, finishing stations, cleaning stations, and more

Accounting for all costs, a single build would cost more than a desktop 3D printer (approximately $3,000, plus usage and labor)

Unsuitable for short batches – costs a lot more per printed product

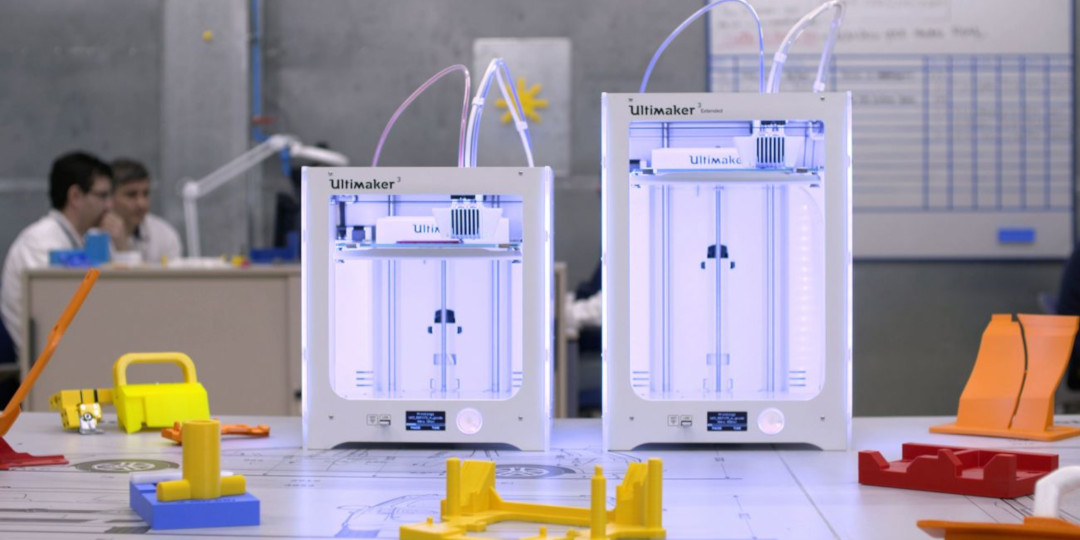

Desktop 3D printers provide a cost-effective and versatile solution

In-house desktop 3D printers

Desktop 3D printers are perfect for rapid prototyping. If you’re doing a lot of printing, a print farm of multiple desktop machines is far cheaper and easier-to-scale than industrial printing. Multiple printers and 3D print clusters also offer more flexibility and control (e.g. printing one part per machine).

Pros:

Most cost-effective option. An outsourced prototype can cost thousands of dollars (for complex models). On average, printing in-house costs a tenth of the price

Quicker turnaround time. Outsourcing 3D printed parts takes about a week. An in-house 3D printer produces a prototype in a matter of hours, shaving weeks off the development cycle. Products can be brought to market in a fraction of the time

Greater flexibility – tweak designs at a far lower cost

No risk of designs being leaked – it’s all done in the safety of your business premises

Total design control – print fine details, smooth surfaces, and even moving parts in a single build

Less room required

Relatively inexpensive and scalable

Cons:

Most desktop 3D printers are technically limited to printing high-performance materials

More suited for smaller-size parts

Not as suitable for mass customization

Employee training is required (but less intense and complicated compared to industrial machines)

Questions to ask

Before committing to a 3D printing solution, ask yourself the following:

What do you need the parts for? Functional prototyping? Visual display? Casting into end products?

What materials will you be using?

How many parts will you need per week? How many parts can you fit into one build volume on a desktop, or on an industrial machine?

How familiar are your employees with additive manufacturing processes? Is additional training required?

What is the timeline for implementing 3D printing into your workflow?

What best suits your working environment?

In most cases, investing in several in-house desktop printers is the best option, then outsourcing final parts with specific requirements to a service bureau. It’s the cost-effective choice, not only for knowledge workers and design or engineering teams, but also for multinational companies. Industrial machines are often underutilized and not worth the investment, unless your business model involves mass customization or low-volume, high-profit activities. If you’re confident that you’ll need large batches of parts with high compliance (e.g. aerospace), then this may be a viable option for you.

Consider not only your current requirements as a company, but what you’re looking to achieve in the future. Cost and practicality should always be a priority, but so too should scalability and creative potential.