Dedicated to promoting inventive art-related exhibits and programs, the Cincinnati Art Museum is exploring the relationship between 3D printing and fashion by highlighting the work of designer Iris van Herpen. With the recent inclusion of an Ultimaker 3 printer, the museum aims to educate visitors about the vast applications of 3D printing and the value it can bring to the creative process where science meets art.

Avant-garde fashion at the Art Palace of the West

The Cincinnati Art Museum is one of the oldest visual arts institutions in the United States, heralded as the “Art Palace of the West” when it opened on May 17th, 1886. Today, the museum boasts over 200,000 square feet and features 88 exhibition galleries, the Mary R. Schiff Library, a conservation laboratory, and more—all of which welcomes approximately 200,000 visitors every year.

Among the museum’s encyclopedic collection of nearly 65,000 objects that span 6,000 years was a recent exhibit on Iris van Herpen, a Dutch fashion designer who specializes in 3D printed attire. In addition to creating two new collections every year, van Herpen participates in exhibitions across the world. The Transforming Fashion exhibit in the Western Southern Gallery at the Cincinnati Art Museum ran from October 13th, 2017 to January 7th, 2018.

The Transforming Fashion exhibit features 3D printed garments by Iris van Herpen. Credit: Cincinnati Art Museum

Iris van Herpen first incorporated 3D printing in her 2012 Crystallization collection and has continued to blend different technologies into her garment creations. Although some of her clothing is fully 3D printed, other modules are 3D printed and then combined with handwork to finish a piece. For Iris, it’s about using the method that will best replicate her vision, which the Transforming Fashion exhibit at the Cincinnati Art Museum showcased in full force.

Setting fashion trends in creative technology

The exhibition boasted impressive origins; it was co-organized by the High Museum of Art in Atlanta and the Groninger Museum in the Netherlands. Items for the exhibit were curated by Sarah Schleuning of the High Museum of Art, as well as Mark Wilson and Sue-an van der Zijpp of the Groninger Museum. Transforming Fashion featured 45 dresses, 9 pairs of shoes, and various samples that allowed guests to feel some of the materials used to create these garments.

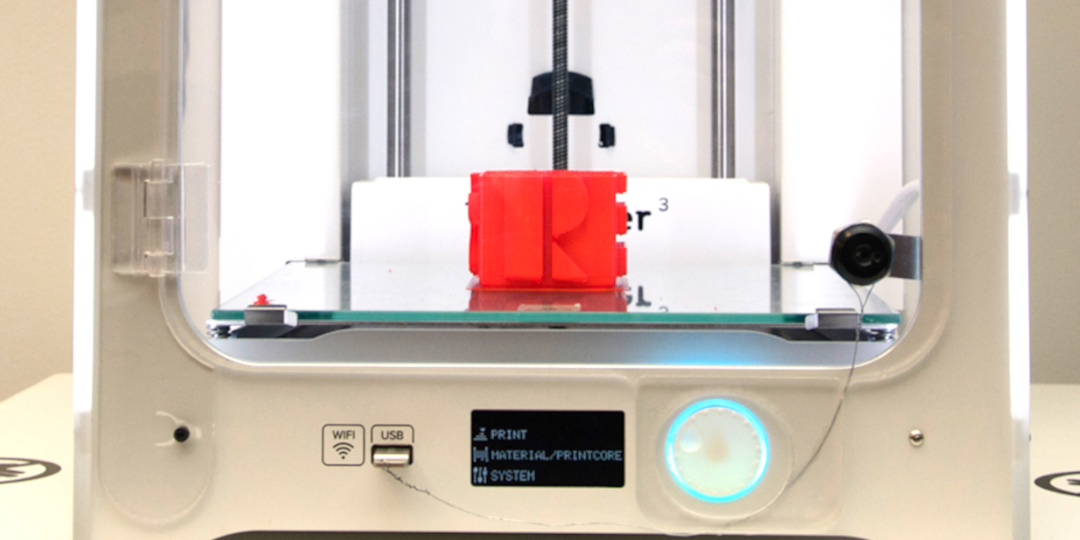

As the exhibit was interactive, it was important that the museum also displayed a 3D printer to highlight the process of creating such unique apparel. By incorporating an Ultimaker 3 into the museum’s program during Iris van Herpen’s exhibit, Alex Otte Callon, coordinator of the Rosenthal Education Center (REC), aimed to spotlight the immersive, hands-on experience of 3D printing and inspire visitors to think of the possibilities it can hold.

An Ultimaker 3 at the REC. Credit: Cincinnati Art Museum

3D prints on display. Credit: Cincinnati Art Museum

“The Rosenthal Education Center has a dedicated interactive space that changes twice a year,” Alex says. “Themes for the interactive space are based on the permanent collection, special exhibitions, and elements of art and world cultures.” Not only did the 3D printer work alongside the fashion exhibit to highlight how such garments were crafted, but also it added to the interactive element that tied together art and education.

3D printing technology is a wonderful example of the kinds of connections and collaborations that can occur between scientific and artistic fields.

Although Iris van Herpen’s work tends to draw a fashion-forward audience, Cynthia Amneus, Chief Curator and Curator of Fashion Arts and Textiles, expected that the technological elements of the exhibit would fascinate guests of all interests and ages. Throughout the duration of the exhibit, Cynthia was interested in drawing a range visitors from architects to engineers and artists, all of whom who would relate to Iris's work. The flexibility of 3D printing across many disciplines and industries is something that visitors of any experience level were able to enjoy, as it gave clear insight into how these tools are incorporated into design and product development.

Demystifying the 3D printer for the masses

The team at the Cincinnati Art Museum was eager to get their hands on an Ultimaker printer when the exhibit first came up as a possibility. “From the moment we put this exhibition on the calendar, one of my top priorities was to have a 3D printer on site,” Cynthia explains. “3D printing is still such a mystery to most people and I thought it was important to demystify the process and educate visitors about how 3D printing works.”

The Ultimaker 3 printer and a finished print at the REC. Credit: Cincinnati Art Museum

It was essential for the REC team to deftly highlight the elements of conceptual thinking and design involved in 3D printing applications; in the case of Iris van Herpen, 3D printed elements are often combined with traditional handwork. The Ultimaker 3 printer, they found, was not only seamless to set up and incorporate self-explanatory but also simple to use when explaining these methodologies. Ultimaker Cura was helpful for slicing models and setting up prints with ease as well, saving the museum time and leaping over learning curve hurdles.

I love how self-explanatory the Ultimaker Cura software is, and how the Ultimaker 3 can basically take care of itself. And if I need to make an adjustment or load new filament, it gives me step by step instructions.

Although Alex was nervous to set up and use a 3D printer without prior experience, she was excited about how simple the process was on the Ultimaker 3. Because of this, the REC team hit the ground running and built a robust exhibit as a spotlight on Iris van Herpen’s impressively innovative techniques.

Examples of Iris van Herpen’s 3D printed work. Credit: Cincinnati Art Museum

“Engineering, philosophy, and creativity meet in van Herpen’s work,” Cynthia says. With notable collaborations that include Benthem Crouwel Architects and Rem D. Koolhaas and clients like Beyoncé, Björk, and Tilda Swinton, van Herpen explores new approaches while pushing fashion to a conceptual and inspirational level. The REC team hopes to continue to encourage visitors who are interested in fashion to explore the world of 3D printing, while those interested in additive manufacturing tools like Ultimaker will recognize the unique application of 3D printing in design.

A 3D-printed future at the Cincinnati Art Museum

The Ultimaker 3 lived in the Rosenthal Education Center for the duration of the Iris van Herpen exhibit, where it remains a part of a variety of projects today. In addition to visitors interacting with the printer during museum hours, REC staff is using the Ultimaker 3 to print an assortment of art objects, wearable designs, and other thematic prints.

Young visitors and the Ultimaker 3. Credit: Cincinnati Art Museum

Learning about the Ultimaker 3. Credit: Cincinnati Art Museum

The team is also working with students at the University of Cincinnati in the Design for America program to develop Cincinnati Art Museum themed prints and build a library of models to use. “This is a technology that is not always accessible to every audience,” Alex says, “so by having it available for the public in a cost-free education center, people of all ages and abilities and backgrounds can learn more about 3D printing and its many uses.”

Now that the Iris van Herpen exhibit is complete, Alex and her team are integrating the Ultimaker 3 into other projects around the museum. They’ll continue to use it for educational purposes as well as benefiting the exhibition design and art conservation departments.