Perfect print profiles

In 2018, Owens Corning and Ultimaker announced a collaboration in which Owens Corning would create material profiles for Ultimaker Cura.

Unlimited application potential.

Specialized for engineering applications.

High-performance and certified materials

Over 300 materials to choose from.

From polymers to composites to metals.

As an industry leader in composite materials, Owens Corning is always looking ahead. But to remain on the forefront of new technologies, the Ohio-based organization must consistently push boundaries. Materials that are stronger, more reliable, heat-resistant – whatever is of potential use to engineers is of interest to Owens Corning.

In 2018, Owens Corning and Ultimaker announced a collaboration in which Owens Corning would create material profiles for Ultimaker Cura.

“We really wanted to leverage all the knowledge and competencies that we have in composite material and apply it to the 3D printing industry,” Emmanuel Vaquant, Additive Manufacturing Platform Leader at Owens Corning, said.

For the collaboration, Owens Corning developed material profiles for two filaments composed of 30% glass fiber – one polyamide, the other polypropylene – which are used for 3D printing with FFF technology. These materials are often used in injection molding, and allow manufacturers to 3D print prototypes and other parts in-house, before entering mass production.

Using these materials – which are part of Owens Corning’s XSTRAND™ line – engineers are able to get as close as possible to actual injection molding, without long wait times or great expense. Owens Corning has done all the legwork in creating the print profiles, and Ultimaker Cura provides the parameter basis that will allow prints to work directly after the profiles are installed from the Ultimaker Marketplace. To start printing, all engineers need to do is click – no optimization necessary.

Emmanuel said the collaboration is not only a win for both Ultimaker and Owens Corning, but for 3D printing technology as a whole. The partnership shows that, provided the opportunity, people can be quick to convert, becoming 3D printer users themselves.

“3D printing is not easy to adopt in an industry,” he said. “If you propose a printer that will be specially adapted to the material, it’s a way to accelerate adoptions [and to ultimately] have an easier and better experience for the end user.”

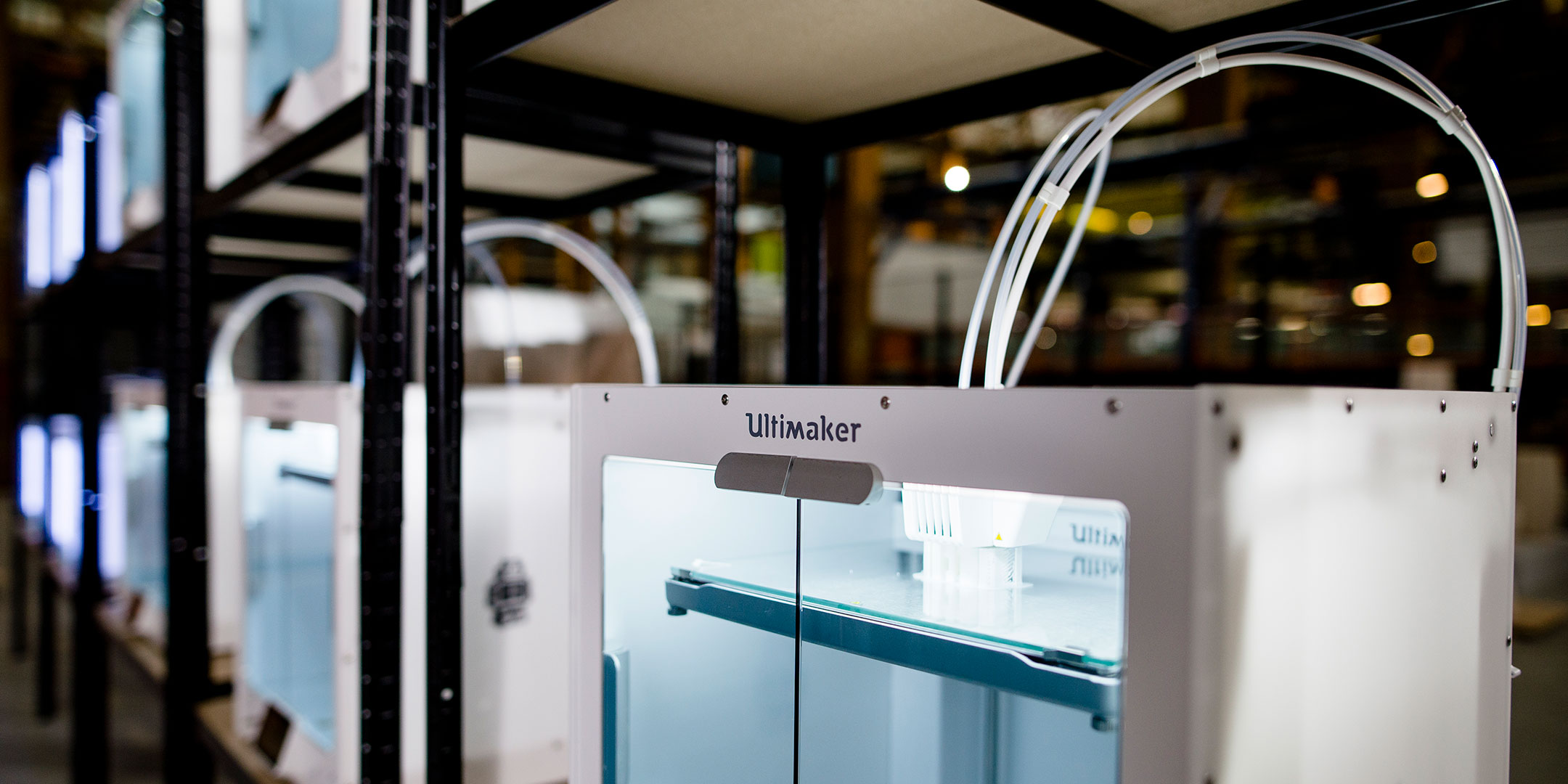

Owens Corning operates innovation labs in Ohio and France that are dedicated to 3D printing. There, experts who specialize in the technology use Ultimaker S5 and Ultimaker 3 printers to create parts for the organization’s manufacturing plants, as well as its science and technology center, to support R&D. These experts take orders, which are usually in the form of quick sketches, from Owens Corning plants around the world and adapt them, so that they are fit to be 3D printed.

This process has colleagues from different continents working, iterating, and creating together. What begins as a sketch becomes an STL file, which in turn becomes a fully functional 3D printed part or prototype. It's a relatively simple process – and a process that works, resulting in plants continuing to submit requests for 3D printed parts.

“It’s nice to see that adoption can be very quick once you create awareness – and when people see the value of this very strong material,” Emmanuel said.

Ready to see what 3D printing can do for your industry? Check out the ‘How Ultimaker unlocks more 3D printing applications’ white paper.