Welcome back to our application spotlight series, where we explore real-world 3D printed solutions delivering faster, smarter, and more cost-effective manufacturing. Each week, we highlight how additive manufacturing can replace traditional methods - saving time, reducing costs, and improving performance.

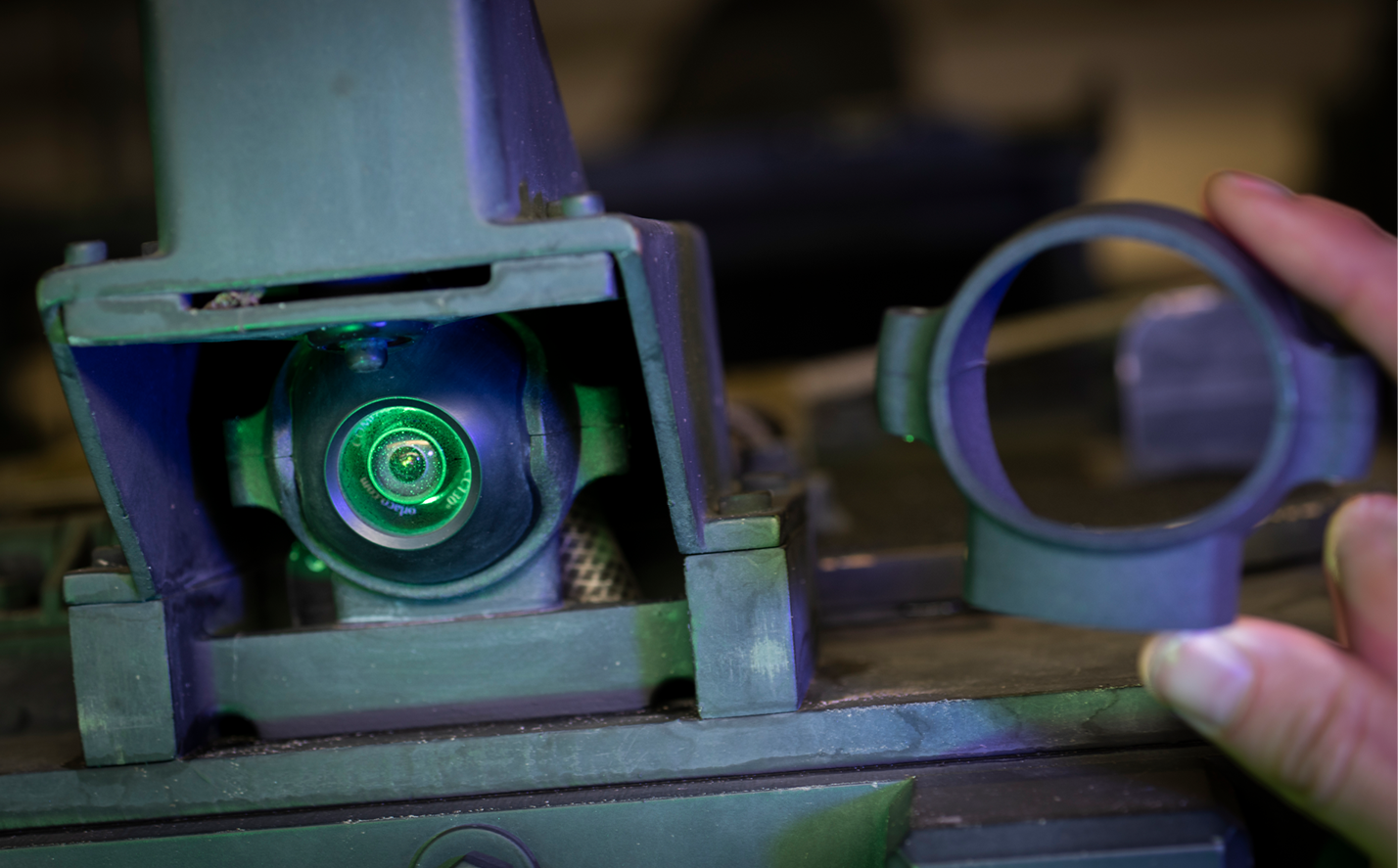

This week, we’re spotlighting a custom 3D printed camera bracket for military vehicles - an essential component produced quickly and affordably with UltiMaker 3D printing technology.

Rapid solutions for mission-critical environments

In defense and security applications, reliable access to spare and replacement parts is vital. A broken or missing camera bracket may seem like a small issue, but without it, situational awareness and operational readiness can be compromised.

Traditionally, sourcing specialized parts like camera brackets involves long lead times, supply chain bottlenecks, or high costs for low-volume production. Additive manufacturing offers a smarter alternative: parts produced on demand, exactly where and when they’re needed.

Faced with the challenge of replacing a bracket, the engineering team turned to 3D printing to deliver a rapid, cost-effective solution.

Strength and precision with PET CF

Using an UltiMaker 3D printer and PET CF, a carbon fiber–reinforced filament, the team printed the camera bracket in a fraction of the time compared to traditional sourcing. PET CF provides outstanding stiffness, wear resistance, and dimensional stability - ensuring the bracket can withstand demanding military environments.