Welcome back to our application spotlight series, where we showcase real-world 3D printed parts that drive smarter, faster, and more efficient manufacturing. Each week, we highlight practical examples that show how additive manufacturing solves everyday industrial challenges.

This week, we’re spotlighting CLIPéFIX, a patented 3D printed clip designed specifically for fruit farmers to secure irrigation lines across orchard systems - where reliability meets real-world agricultural needs.

Smart farming starts with smart parts

For fruit growers, maintaining consistent irrigation is essential to crop health and yield. But in open-field environments where heat, frost, and UV exposure are daily challenges, even the smallest components—like irrigation clips—need to be engineered for endurance.

That’s where CLIPéFIX comes in.

Developed by DP3D for a fruit farming company, this 3D printed part is designed to hold irrigation pipes firmly in place, ensuring reliable water delivery throughout orchards. Unlike traditional off-the-shelf clips that crack or degrade under harsh conditions, CLIPéFIX was tailored to perform in the field - and last.

Built to endure, batch after batch

Each CLIPéFIX part is printed using ASA material, selected for its:

- High resistance to UV exposure

- Stability in extreme temperatures (from -8°C up to 47°C)

- Long-term durability outdoors

First field-tested in late 2021, CLIPéFIX has since proven itself across multiple harvest cycles. Today, DP3D produces up to 1,000 units in just two weeks, meeting seasonal demand with consistent output and quality.

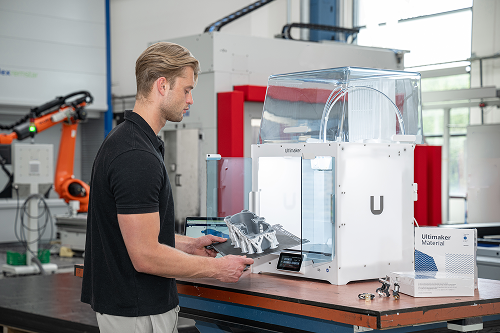

This production reliability is made possible by the UltiMaker S6, which brings industrial-grade performance without the complexity of traditional manufacturing methods.