Welcome back to our application spotlight series, where we explore how UltiMaker 3D printing technology powers smart solutions across industries. From speeding up production to cutting costs, each story shows how additive manufacturing is changing the way companies operate.

This week, we’re heading to sunny Seville to see how the Heineken brewery optimized its packaging line with a simple but effective 3D printed solution: the conveyor wedge.

Keeping products on track

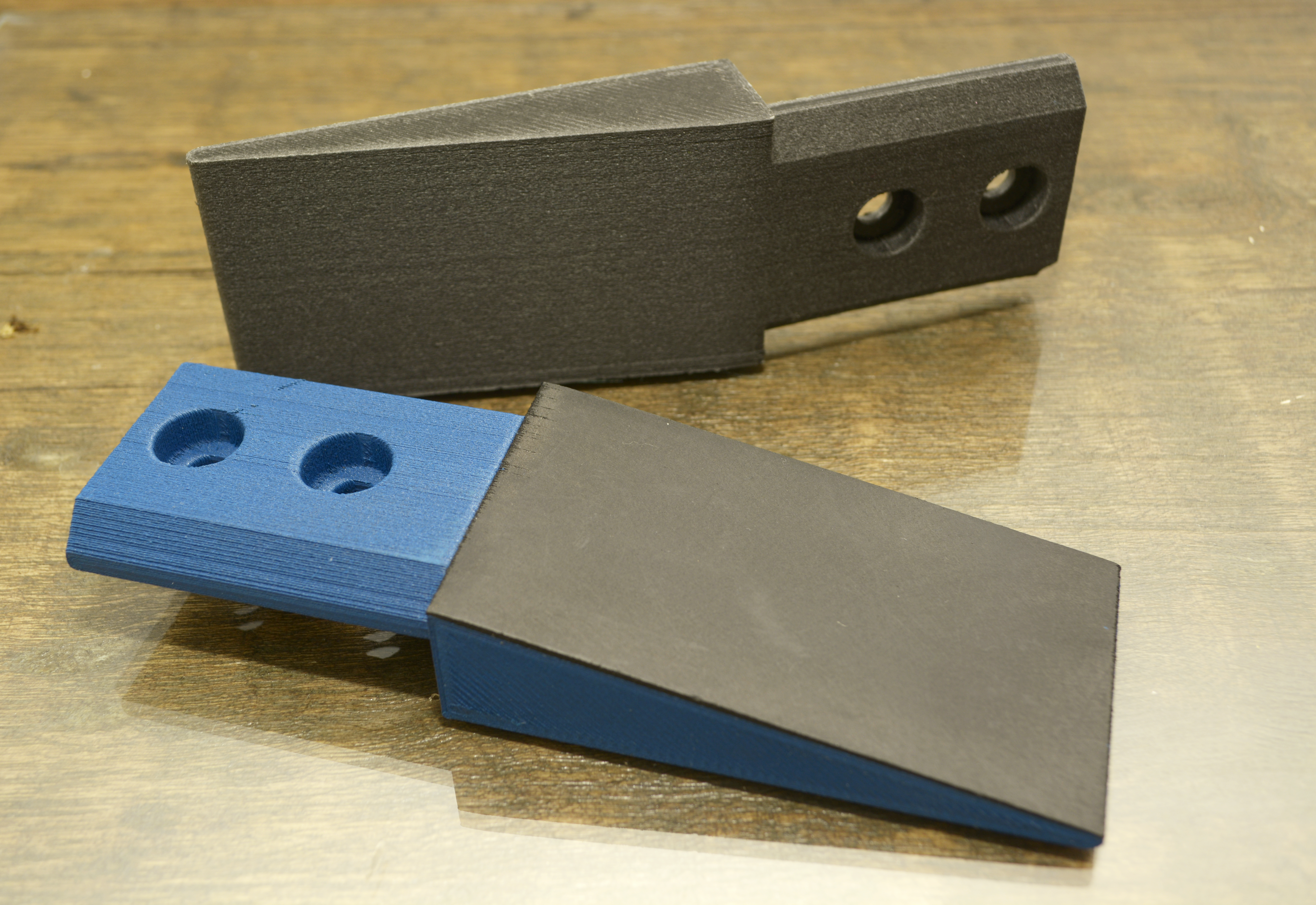

In high-speed packaging environments, even small guiding components play a crucial role. A conveyor wedge is an element mounted alongside a conveyor belt. Its job? To align, stabilize, or divert products as they move through the system, without gripping or touching them actively.

For Heineken’s Seville brewery, ensuring smooth transitions and proper product orientation was key, especially in tightly spaced conveyor layouts. But sourcing custom components like these through traditional manufacturing was costly and time-consuming.

Wear-resistant solution with in-house 3D printing

By turning to 3D printing with UltiMaker’s Nylon CF Slide, the brewery was able to produce a durable, low-friction wedge in-house, tailored exactly to the line’s specifications. The part’s wear-resistant surface and mechanical strength made it ideal for continuous operation. With dual extrusion, it is even possible to create a "wear indicator" for when the part is wearing out to a critical stage and prepare for replacement in time.

Resources saved

Switching to 3D printing brought dramatic efficiency gains:

- Cost savings of €9,901.50

- Lead time reduced by 90%, saving 2.5 days