3D printing is no longer just being used for prototypes. It’s also effective for producing small batches of products – invaluable if you urgently need a specific part in order to launch on time. Prior to our launch, we put the Ultimaker 3 to the test, bridge manufacturing an improved part to ensure we met our release date. We’re pleased to say that the Ultimaker 3 exceeded expectations, proving itself to be production-ready, reliable, and able to deliver results.

Improved reel holder design

In the lead-up to Ultimaker 3’s launch, we significantly altered the design of the reel holder. There was a reason for this. Ultimaker 3 is a dual extrusion printer, which means it can print with two different materials. We realized that, in order to stop the filament becoming loose on the existing reel holder, we needed to incorporate a customized anti-entanglement clip.

That wasn’t all. In a bid to deliver an even more enhanced 3D printing experience, we also equipped the machines with an NFC scanner. It allows the Ultimaker 3 to detect and identify the material being used, and then check that the corresponding filament and print core are correct.

Putting back the deadline?

These developments ensured the Ultimaker 3 would perform to even higher standards. But it also meant that both the Ultimaker 3 and Ultimaker 3 Extended wouldn’t be completed to deadline, which would delay the official launch.

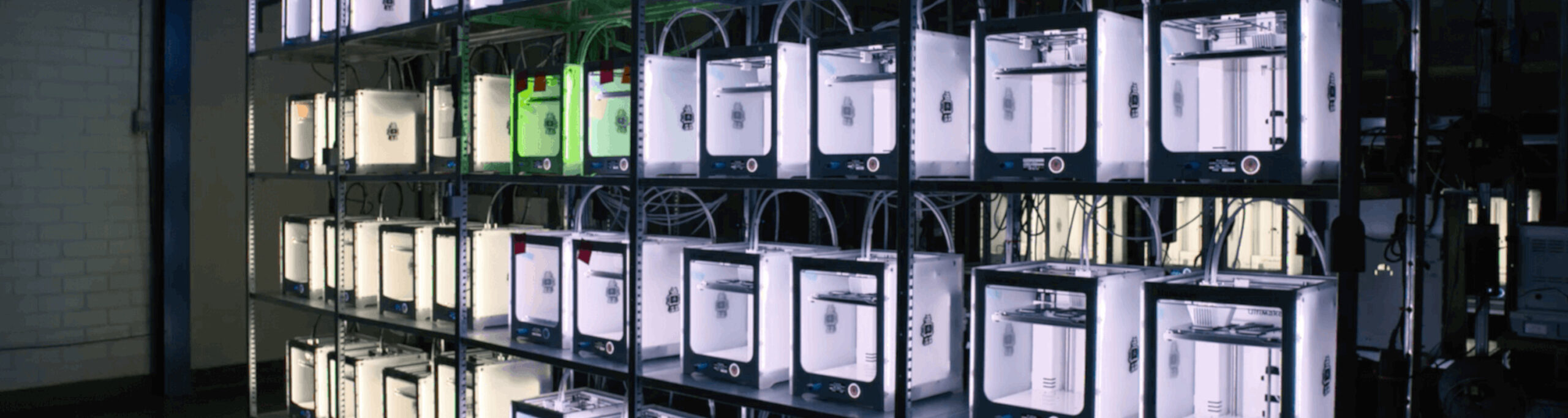

Naturally, we weren’t enthusiastic about the prospect of postponing the release, so we sought to address the issue. The solution was obvious. We would use the print farm of 28 Ultimaker 3 machines in our production facility in Zaltbommel, and 3D print the newly developed reel holder ourselves.

Putting the Ultimaker 3 to the test

Indeed, bridge manufacturing breaks down barriers that businesses have been facing for years and opens new ways to approach product development, testing, manufacturing, and time-to-market.

On this occasion, the Ultimaker 3 delivered great results. We managed to get the updated reel holder out on time and at a low cost, which was an added bonus. Just as importantly, we got to test our latest printer - in a comprehensive, rigorous, time-sensitive format. The Ultimaker 3 performed fantastically, proving that it was fully production-ready, reliable and highly accurate.

The print farm

Managing an Ultimaker print farm is actually surprisingly simple, and can be maintained and supervised by just one full-time employee. With the Ultimaker 3’s connectivity feature possibilities for manufacturers are almost endless. Users can print wirelessly and can even monitor the process remotely via a live camera.

To give you an idea of production capacity, our 28 printers allowed us to produce 700 spool holders for our first customers, in under 4 weeks. With everything set up, we achieved a print success rate of over 86% and a calculated average uptime of 92%. Now that’s impressive.

Part of the reason we enjoy these levels of success is down to the right material choice. The Ultimaker 3 lets you print using two different materials – the build material and an accompanying support material. This, combined with the open filament system, gives professional users complete dimensional freedom. To create the improved reel holders, we used black PLA and water-soluble PVA.

Post-processing

To keep the print process as efficient and quick as possible, our operator removed big blocks of PVA support structures; either manually or with pliers. Dissolving the remaining PVA was easy. We placed the parts in a bath (under 30˚C) with water pumps. After being left overnight, the parts just needed to be dried and quality-checked before assembly the next morning. The accuracy was excellent. The proof is there to see – the Ultimaker 3 performs to high standards and is very reliable.

Delivering the goods

Thanks to the Ultimaker 3 and bridge manufacturing, we were able to deliver the redesigned reel holder on time, at low production costs. We were also able to road-test our printers thoroughly, which delivered even greater confidence in the product.

If you purchase one of the first Ultimaker 3s, you’ll receive the 3D printed spool holder. The injection-molded version will be supplied shortly after. This means you can start using your new Ultimaker without any hold-ups or compromise on quality.

As Paul Heiden, our Program Manager, concludes: “It’s actually a wonderful idea that the first reel holders that come with this machine are actually the ones that the machine produced itself.”

Why use bridge manufacturing?

There are a number of benefits to using bridge manufacturing, including:

More focus on R&D. Bridge manufacturing lets you deliver the product to customers, freeing up time to focus on research and development.

Lower costs. There’s no need for high upfront investments in tooling.

Reduced risk. Bridge manufacturing allows you to verify your design before tooling, confirm its manufacturability, and check that it’s fit for purpose.

Less hold-up. The flexibility that 3D printing offers means you can produce a batch of the end-use part you need without holding up production - or delaying your launch date.

With 3D printers, prototypes can be produced faster – this leaves far more time for research breakthroughs. It’s a bridge technology that allows us to produce a small number of systems at a low cost.

The Ultimaker 3 offers industrial-grade results, whilst remaining accessible for all. With a range of innovative features, including water-soluble support, dual extrusion, and swappable nozzles, it offers limitless new design possibilities. Thanks to bridge manufacturing, you can start using it today.