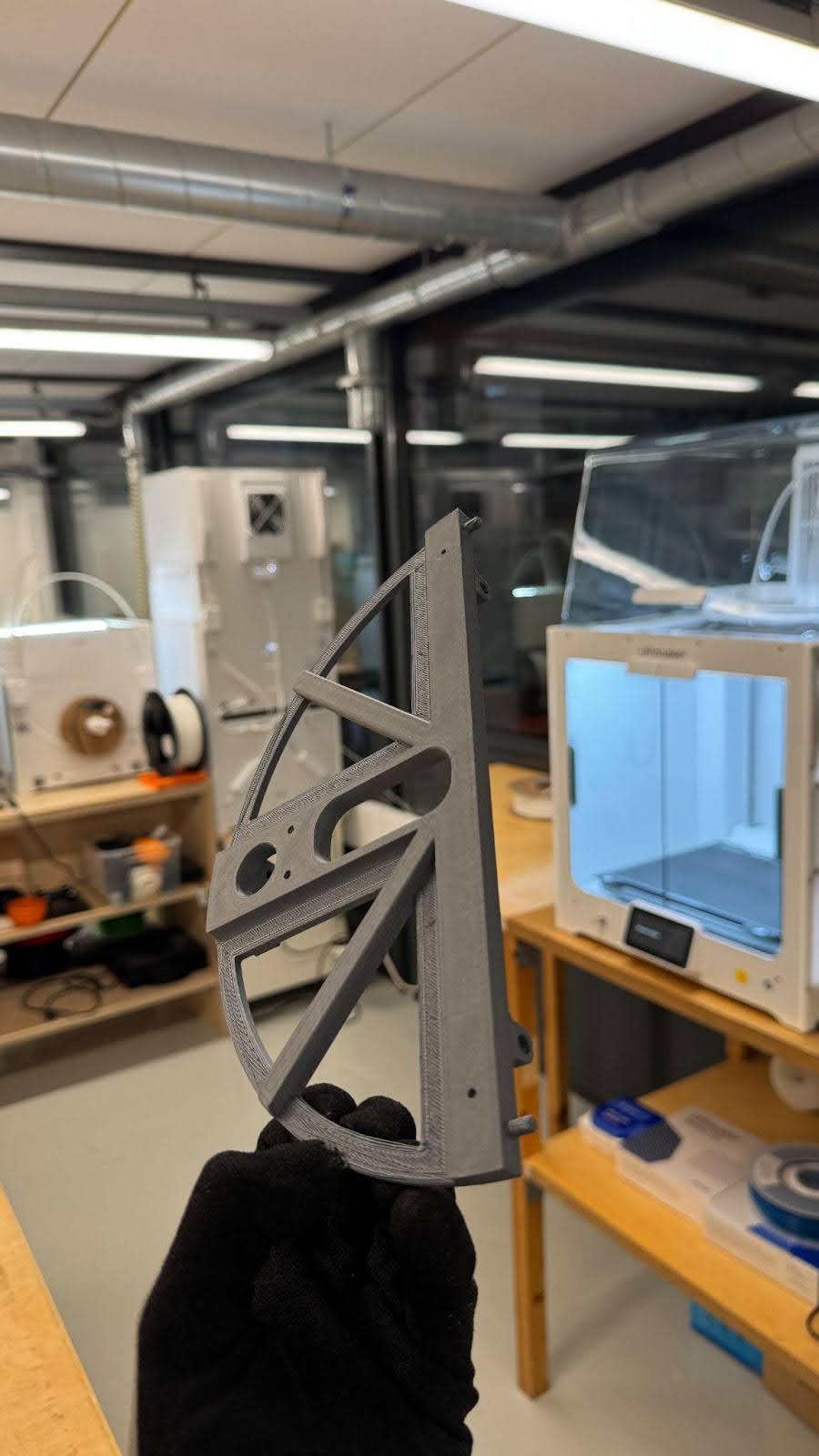

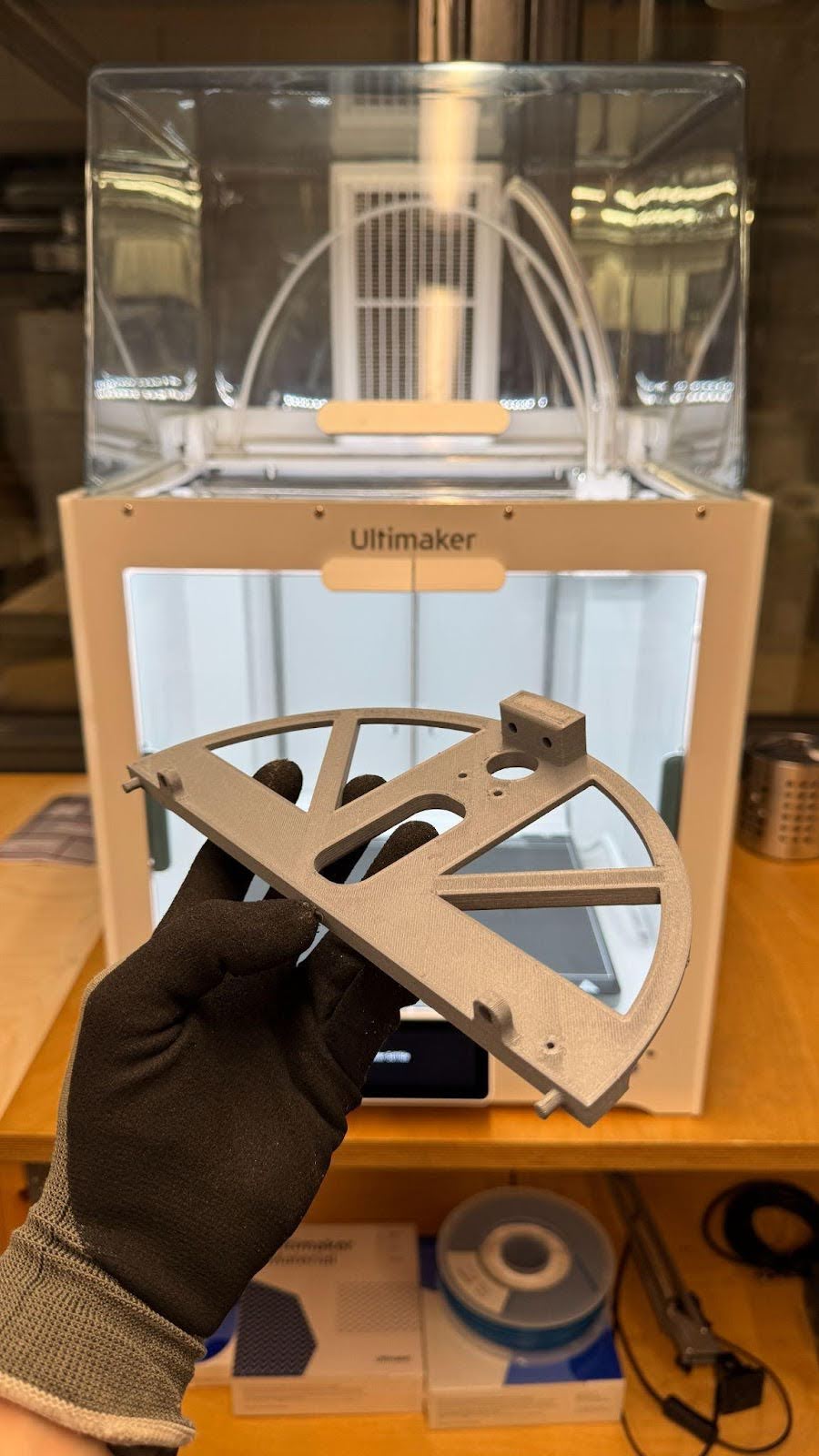

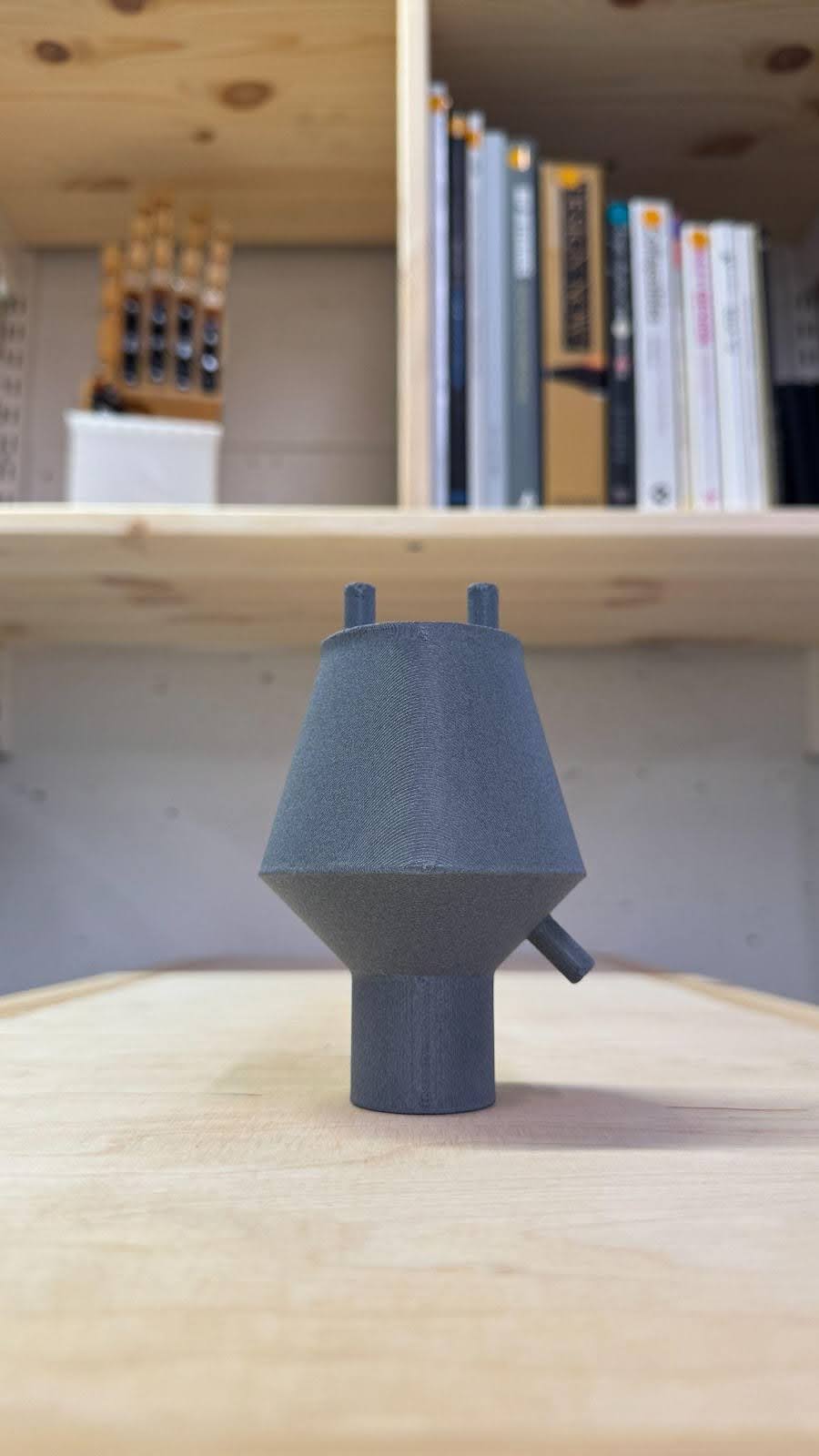

(Prototypes of a part for one of Erwin Laiho’s sculptures printed out of white tough PLA.)

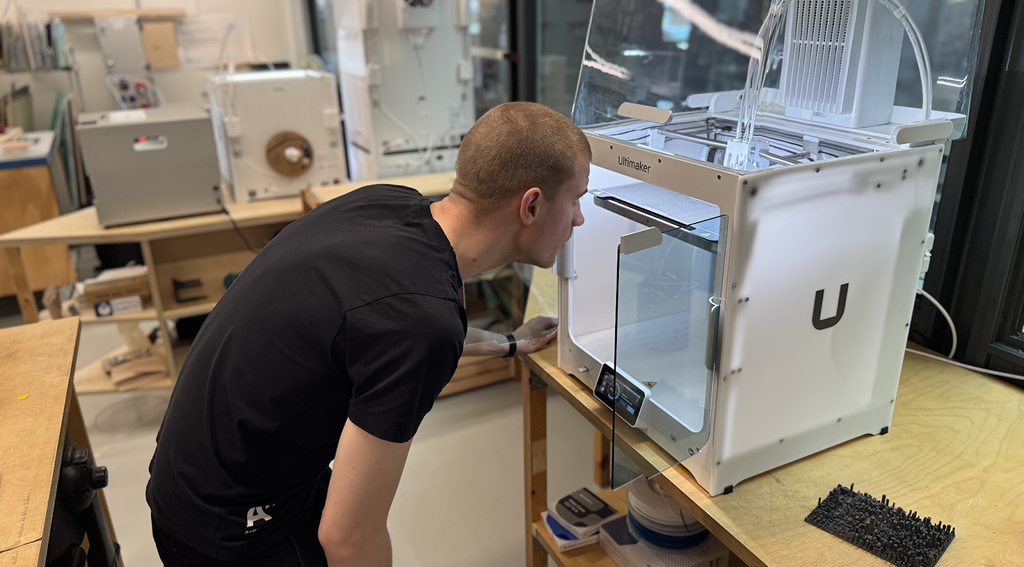

We’re responsible for the lab environment, and reliability matters.

The shift from the S7 to the S6 was smooth, and the team now relies on the S5 for large-spool jobs, while the S6 handles rapid prototyping with consistent quality. Thanks to the Material Station, Erwin and his team can keep printing continuously with peace of mind.

A partner in innovation

Through their ongoing partnership with Finnish reseller Maker3D Aalto University benefits from expert support and access to new materials.

Maker3D has been a great local partner, says Erwin. “In this field where so many aspects are digital or virtual, seeing things in practice matters - having someone nearby who understands the equipment makes a difference."

As Aalto University continues to push the boundaries of design education, the UltiMaker ecosystem plays a key role in helping students test ideas, fail faster, and succeed sooner.

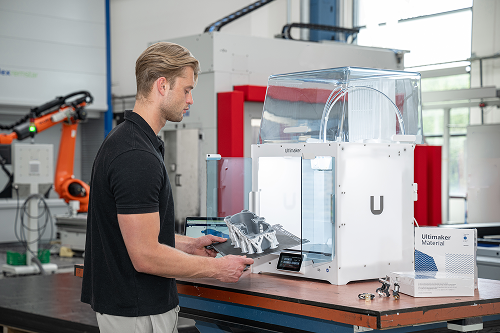

Advance your learning and design with the UltiMaker S6

Whether you're managing a university lab or running industrial-grade prototyping, the UltiMaker S6 offers a fast, reliable, and flexible solution.

Join institutions like Aalto University in discovering the power of productivity-driven 3D printing - with access to hundreds of materials, software integration, and support when it matters.