As a renowned institution, the Massachusetts Institute of Technology strives to prepare students for a world rich with entrepreneurship. A 2015 report found that businesses created by MIT graduates employ over 4 million people, and about 40% of MIT founders end up starting more than one company. Eager to give young minds the tools they need for success early on, the school’s summer program for high school students—MIT Launch—aims to embolden tomorrow’s innovators with today’s emerging tech skills like 3D printing.

Empowering students to build real startups

Located at the Massachusetts Institute of Technology, MIT Launch is a program suited for high school-aged students interested in entrepreneurship. Each summer, the school accepts two groups of 80 students for a four-week immersive experience in which they learn how to bring startups from concept to market.

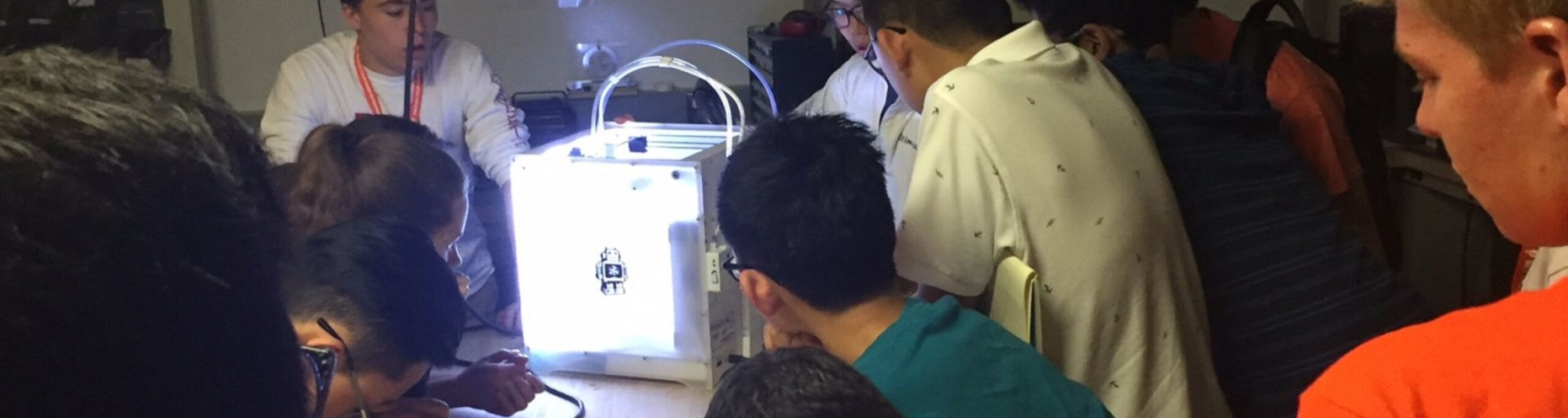

A student group presenting their product. Credit: @LaunchSummer on Twitter

With ages ranging from 14 to 17, the students are ambitious high schoolers interested in learning everything the esteemed program has to offer them about ideation, production, and marketing. Mariah Ramos, the Partnerships Manager for MIT Launch, says that the process of prototyping and 3D printing makes the creation of a minimum viable product a seamless operation; one that allows each team to collect valuable customer data with the minimum amount of effort.

Our goal is to help students design and prototype a product so that they may test that product in the market as quickly as possible.

By pursuing real customer feedback and product testing, the students have the opportunity to pivot or optimize their solutions efficiently. This hands-on program encourages the designing and testing of products quickly, which motivates students to stay sharp in a swiftly evolving technological world.

A product developed by one group of MIT Launch students, which makes 3D printing more accessible to the public.

Prototyping for creative solutions

The overarching goal for MIT Launch, Mariah says, is to bring entrepreneurship education to high school students everywhere. “We want schools to empower students to come up with creative solutions to the world’s problems,” she further explains. Those working within the program have found that 3D printing is the perfect vehicle for delivering the skills these students need to succeed.

3D printing encourages students to become entrepreneurs, empowering them at the high school age to prototype their own future.

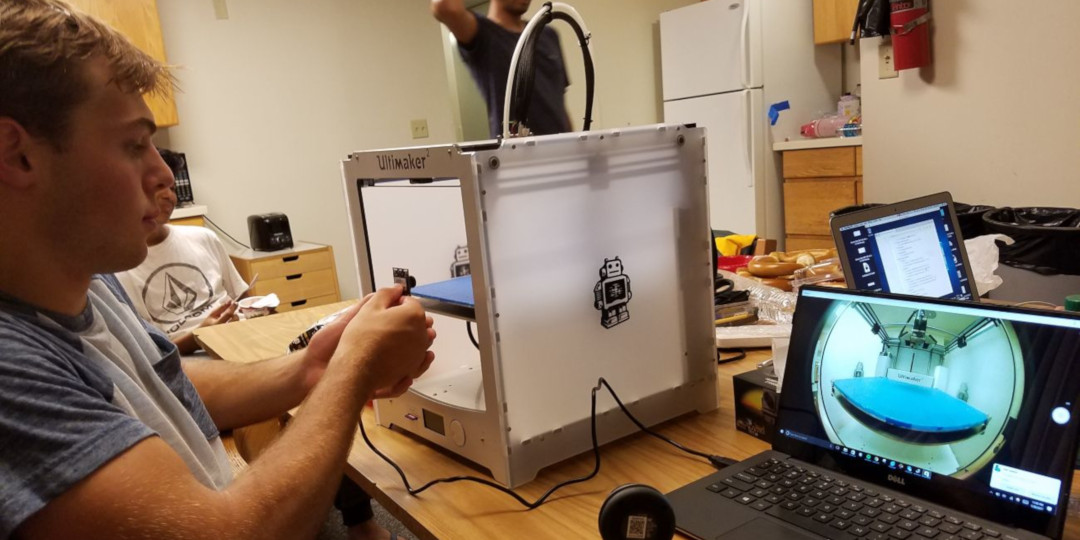

MIT Launch participants setting up a camera on an Ultimaker. Credit: Nate Houston

The 3D printing process facilitates early adjustments and testing adaptations, which further enhances the entrepreneurial mindset they’re hoping to instill. Being able to take action so quickly with an accessible, affordable 3D printer is vital to this process, Mariah says, which greatly impacts their need for Ultimaker.

Swift product testing with Ultimaker

Speed, quality of the product, and safety were important to MIT Launch staff when incorporating a 3D printer into their program. Ultimaker not only delivered an affordable solution that gave students the opportunity to print in their high schools and homes, but also provided the additive manufacturing knowledge they need to carry through their entrepreneurial journeys.

Fisheye lens view set up by students.

Bringing the latest in 3D printing technology into the program has allowed students to discover their own capabilities in creating a startup while still in high school—and they love it, Mariah says. Producing a product so quickly on Ultimaker legitimizes their ability to become entrepreneurs, especially at such a young age.

Using Ultimaker, many of them were able to develop an initial prototype in the first week of the program.

If they succeed at helping students find their passions early on in life, the MIT Launch team knows they’ve given young learners direction for the future; an essential first step to finding success in the business world.

Real-world problems: solved

One of the 160 MIT Launch participants says that he was interested in the summer program because it provided a chance to do and build something real, solving problems that apply to his generation. The student’s team built a device called Optic that can be used to help the vision-impaired read and learn braille, with the goal of increasing job opportunity for the blind.

A product developed by MIT Launch students that makes it easier for the visually impaired to learn Braille.

Throughout the process, using an Ultimaker allowed the team to see faults in their original product and improve it quickly. With the help 3D printing and testing phases, they exposed flaws in their thought process and were able to see the product from a consumer standpoint.

It was a helpful tool for collaboration, too. “We are aspiring entrepreneurs with different life paths,” the student says. “However, this program brought us together from all over the world—it was great to share our ideas and energy with similar-minded students.”

We want to inspire students to be their best and make the change they want to see in the world!

In addition to their summer program, MIT Launch offers Launch Clubs to provide the same experience to students during the school year, and an online course called LaunchX that guides first-time entrepreneurs through the process of starting their own company.

By challenging students and encouraging innovation through the latest technologies, Launch is undoubtedly preparing young minds for the challenges that lay ahead. The minds behind MIT Launch understand that there are limitless possibilities for 3D printing, and that those prospects open doors for philanthropic endeavors.

Browse our Explore pages for more stories on 3D printing applications in education!