April Jubett’s background in scientific illustration and 3D animation paved the way for her work with NASA's Chandra X-ray Observatory, a space-based telescope that orbits our planet collecting information for scientists. She began working on Chandra’s communication team fifteen years ago, exploring her strong desire to explain science through creative mediums like 3D printed models. With the help of Ultimaker, April and her team make it possible for inquisitive learners of all ages to hold supernovas right in the palm of their hand.

From mapped data to palm-sized supernovas

The Smithsonian Astrophysical Observatory (SAO) in Cambridge, Massachusetts controls Chandra's science and flight operations. SAO, partnered with the Harvard College Observatory to form the Harvard-Smithsonian Center for Astrophysics, is one of the research branches of the Smithsonian Institution. They work with telescopes of heightened sensitivity and resolution in order to study the cosmos and make groundbreaking discoveries, sharing their research through innovative means.

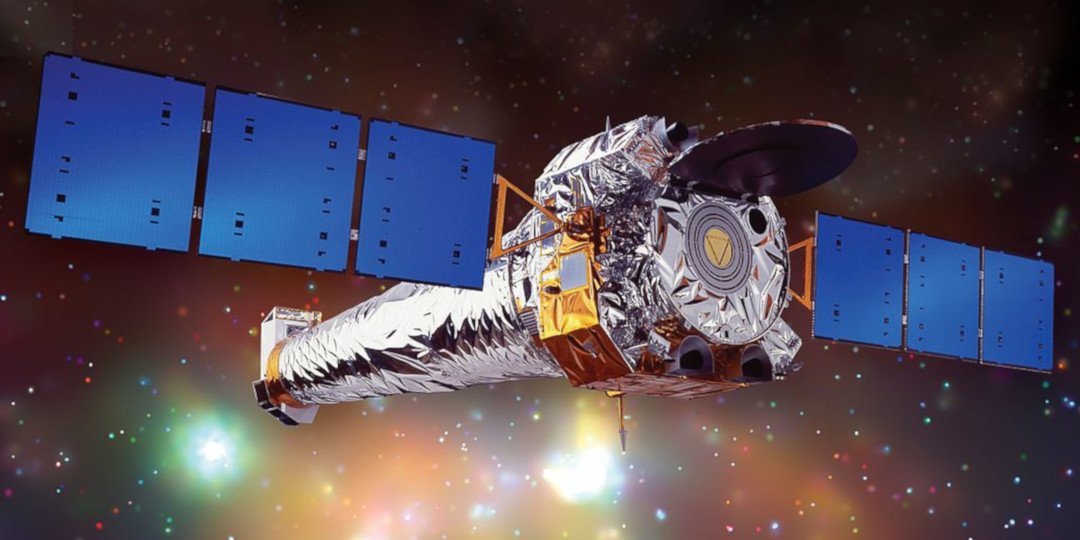

An artist's rendering of the Chandra X-ray Observatory. Credit: NASA/CXC/NGST

The sole purpose of NASA’s Chandra X-ray Observatory is to amass data in the form of X-ray light from high-energy objects—such as exploding stars and black holes—within and beyond our galaxy. Incorporating the latest technologies into their processes, Chandra’s Communications and Public Engagement group, of which April has been a member since 2001, creates 3D models and 3D prints in order to raise awareness and further understanding of our high-energy universe.

With recent breakthroughs, such as our ability to map X-ray data of astronomical objects in three dimensions, my team has expanded its role to include 3D printing of such objects, and now even virtual and augmented reality experiences around those data sets.

While they’ve found that videos and podcasts are an effective way to explain science to the masses, holding a 3D print is invaluable for learning about otherwise unreachable phenomena and data. “We use our 3D prints with people of all ages and of varying interests and abilities,” April says. “The idea of holding a ‘dead star’ in your hand seems to appeal to most people with a curious mind. We can use our prints to help explain basic X-ray astronomy, physics, and technology to even very young children.”

A student examining a 3D printed model and print. Credit: NASA/CXC/A. Jubett

Another student watching the Ultimaker 3 in action. Credit: NASA/CXC/A. Jubett

April’s team runs STEM workshops for middle school and high school students interested in learning about the Chandra mission and the evolution of the stars, utilizing the 3D printed models as hands-on learning tools. In addition, they work with blind and visually-impaired communities. Having 3-dimensional models of objects that were previously only represented as 2-dimensional images allows her team to provide much more accessible education to learners of all ages and capabilities.

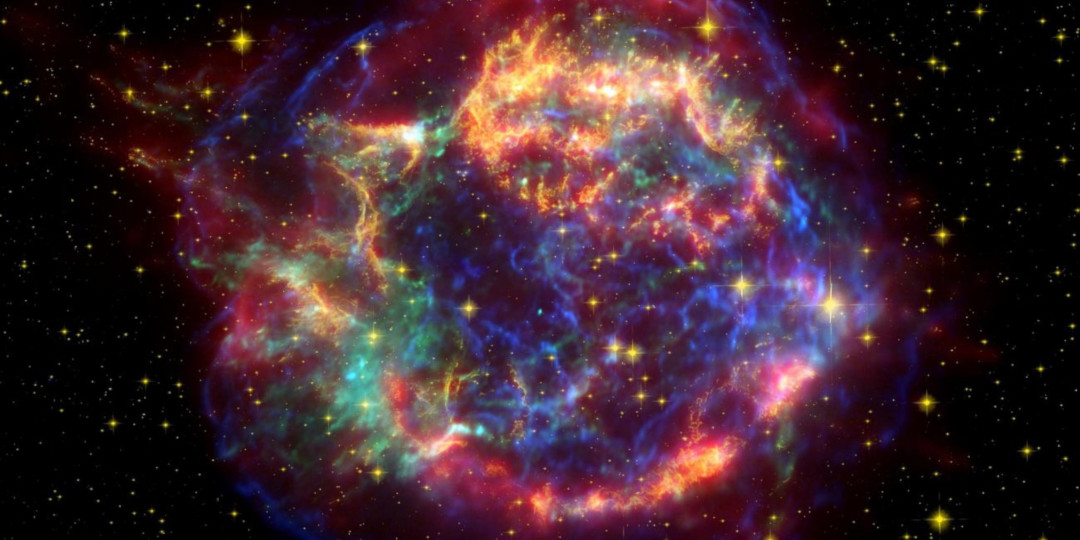

Cassiopeia A was the first model printed in 2014, though April and other members of the Chandra group had been working with models of the exploded star since the 3D mapped data was created by astrophysicist Tracy Delaney in 2009. “3D printing the Cassiopeia A model and others that have followed was a logical progression of my skills and interests,” April says. Despite lacking the first-hand experience with 3D printing, April was able to pick it up through trial and error, as well as with the help of more experienced users along the way.

A false-color image of Cassiopeia A. Credit: NASA/JPL-Caltech

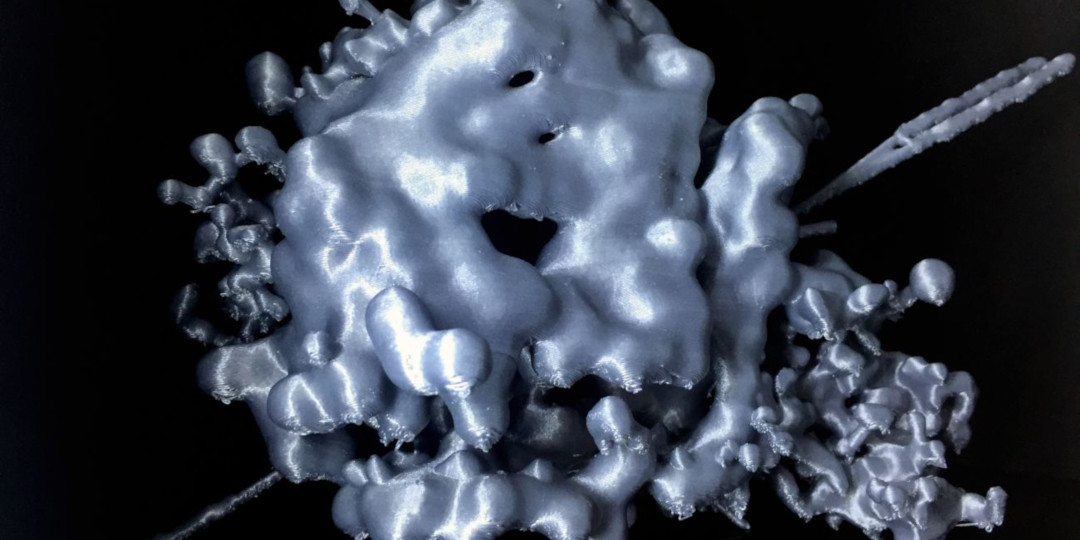

A 3D printed model of Cassiopeia A. Credit: NASA/CXC/K. Arcand

PVA supports for quality 3D printed stars

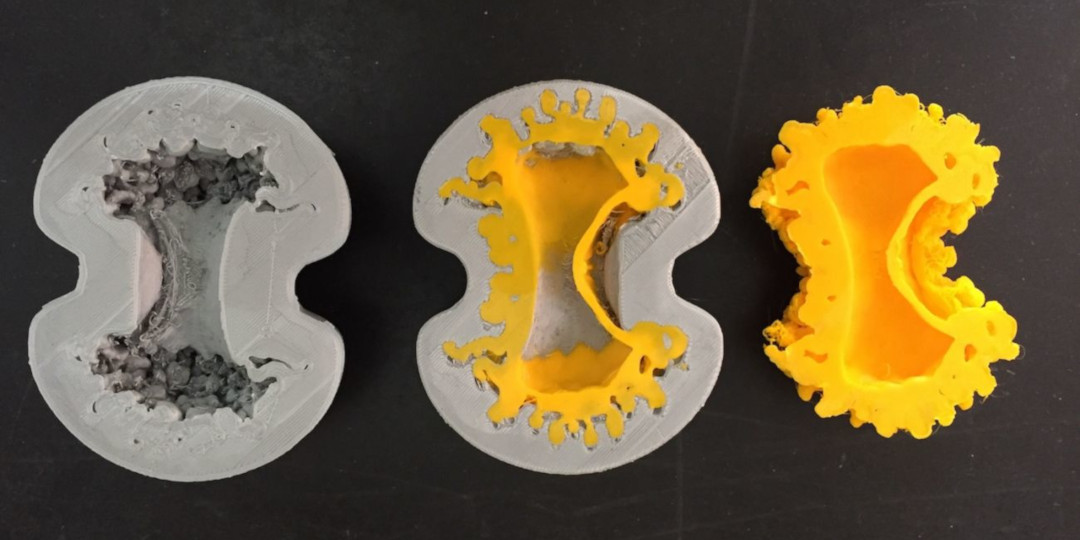

Although the Chandra X-ray Observatory does not endorse any commercial product and aims to use all available tools for greater flexibility, the 3D printing program at Chandra has an Ultimaker 2+ and an Ultimaker 3 on hand for model making. Dual extrusion is one of the features that the team enjoys most about their Ultimaker 3, allowing for more than one color filament and the added benefit of water-soluble PVA supports.

The use of 2-color printing and dissolvable filaments for support and print-bed adhesion has been important. It is so much faster to not have to hand-remove the support structures, and we get a better quality print as a result.

Despite mainly printing with PLA and PVA, April has experimented with ABS and is interested in branching out to other materials in the future. The Ultimaker printers at Chandra often run 24/7, though trial and error for designs sometimes results in one model per week. In the future, April hopes to be able to produce better 3D files from mapped X-ray data that will result in prints with shorter production time and greater durability.

Three models of Supernova V745 Sco. Credit: NASA/CXC/A. Jubett

Expanding their efforts for education, it’s important to the team that they provide STL files for anyone to print, encouraging students to get involved with Tinkercad and lessons on 3D modeling. They’ve already begun compiling files for download on the Chandra X-Ray Observatory website, with 3D models of supernovas and the Chandra spacecraft available to those interested in this research.

With the help of 3D printing, April and her team at the Chandra X-Ray Observatory have seen success in translating scientific data into tangible learning tools that anyone can use. “In my experience, it helps to use a mixture of technical (but non-jargon-loaded) and common language,” April says, “combining animations and other visual or tactile aids with hands-on experiences.” Through these innovative technologies, deep-space phenomena is simplified with everyday physics experienced on Earth, satisfying curious minds of all ages.

Sources:

Arcand, K., Watzke, M., DePasquale, J., Jubett, A., Edmonds, P., DiVona, K., "Bringing Cosmic Objects Down to Earth: An overview of 3D modeling and printing in astronomy" Communicating Astronomy with the Public. issue 22, p. 14. 2017. Arcand, K. "How To Hold A Dead Star In Your Hand" Forbes Starts With a Bang, 2016.