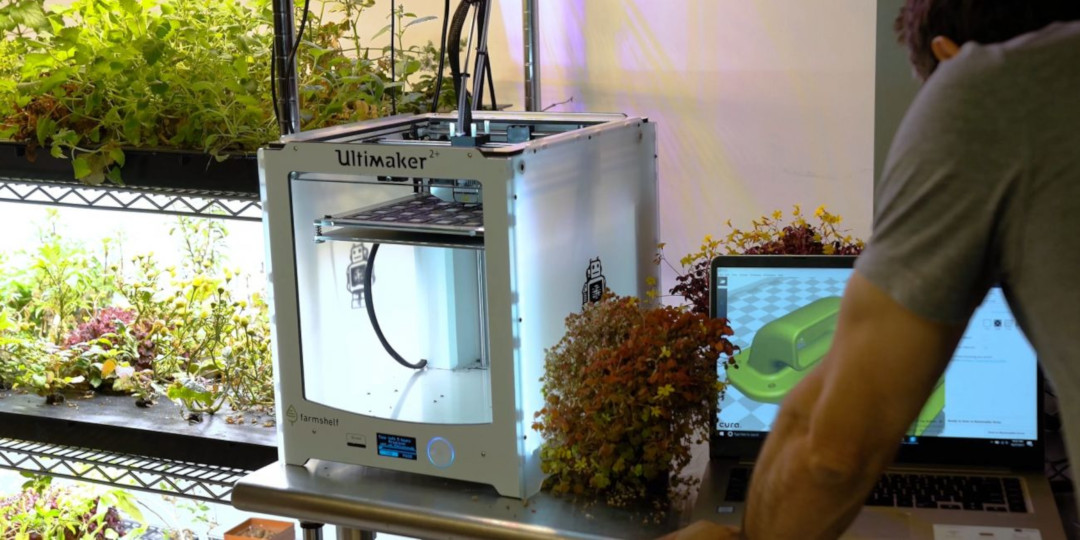

Farmshelf has carved out a place for itself in the urban farming space by creating a fully autonomous system that allows individuals, residential communities, and restaurants to grow food on-site. In order to create, test, and refine their unique hardware and software platform, they made extensive use of Ultimaker 2+ printers that allowed them to produce many design iterations for a large system of modular custom parts, a process that would otherwise have taken too much time and money to outsource.

Although the Farmshelf team had a clear idea what they needed to accomplish with their flagship product, engineering autonomous processes involving living, growing organisms can be a serious challenge. In addition to meeting stringent engineering requirements for each component and subsystem, they needed to produce a lot of customized plant housings, mounting brackets, and more.

They also needed test those parts through harvest after harvest of a wide array of edible plants. Traditional fabrication methods would not only have meant dishing out too much money—impossible for their efforts to grow a successful company—but any misstep with traditional manufacturing would have cost them a garden’s worth of crops, and months of effort.

Freedom to design and iterate

Andrew Shearer, CEO and Co-Founder of Farmshelf, understood early on the value that 3D printing could bring to his business. “As a company, you can now look at 3D printing as a way to involve more people in the building process, and involve more in the prototyping and dreaming process, thanks to how easy it is,” Andrew says.

Andrew Shearer checking on plant pods

By choosing to integrate Ultimaker printers into their design process, Farmshelf was able to shape and reshape custom parts on the spot. As a result, they maintained challenging production needs necessary to produce functioning, plant-ready prototypes for their earliest products. Instead of rolling the dice to determine the success and failure of the company with every round of custom parts, Farmshelf discovered a budget-friendly solution for every stage from prototyping to production; 3D printing accommodated all of their needs for design and laboratory research.

As we approached prototyping all of these parts, Ultimaker proved to be a great solution. For all the different needs we’ve had, from prototyping to small batch, short-run production parts, this technology enabled us to push forward our timelines, and keep this company on the fast track. It is always tough to build hardware, but Ultimaker makes it a lot easier.

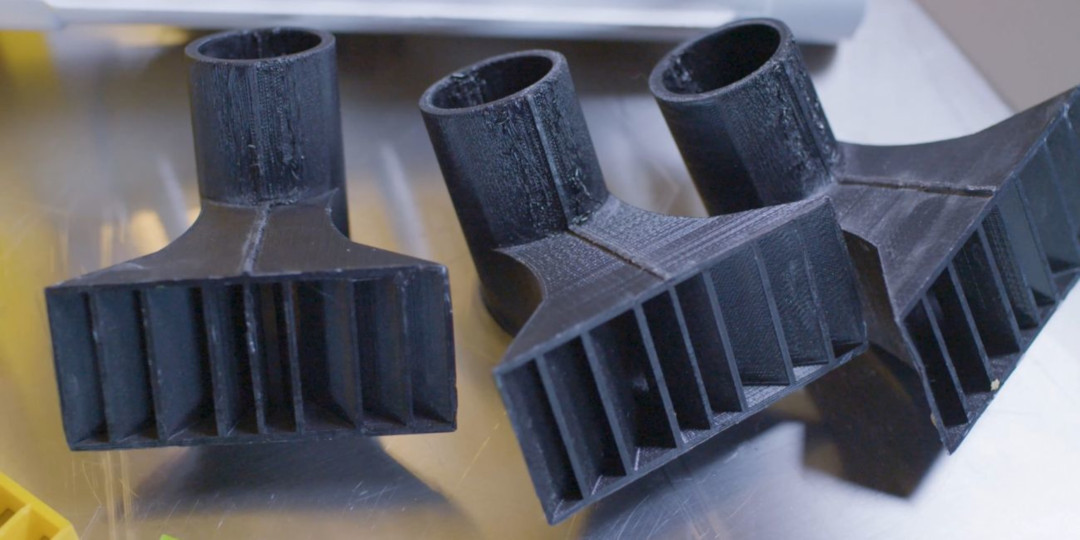

A close-up of a Farmshelf plant pod

With 3D printing available in-house, the Farmshelf team only had to shoulder the cost of filament for their prototyped parts. Outsourcing would have resulted in materials, supplies, and service costs, as well as a bottlenecked iteration process while waiting for new rounds of custom parts, slowing everything down.

“Without access to the Ultimaker printers, we would have had to resort to using off the shelf components, and would have had to design our product around those off the shelf components,” says Jaeseong Yi, Product Designer at Farmshelf. “Or worse, we would have had to extensively machine parts using CNCs, which can be a time-consuming and expensive process. Having the Ultimaker machines really empowered us in our design process.”

Product expansion and installation

The results were immediate rewards for Farmshelf’s design team. Not only did they have the freedom to customize parts quickly and efficiently, but also they had functional prototypes in hand that allowed them to test products through entire growth cycles of plant pods. In turn, product expansion was a much more efficient and money-saving process, allowing the team to install and exhibit beta models at various high-profile public sites without breaking the budget.

Farmshelf plant pod designs loaded into Ultimaker Cura

“The Ultimaker 3D printers, in the simplest terms, made it even possible for us to build early Farmshelf prototypes,” says Gabe Benton, Farmshelf’s botanist and the lead Ultimaker operator in the early stages of the business. “Without them, given the number of plastic parts that we use in the system that are custom, I cannot even imagine how many tens of thousands of dollars it would have cost us to make those sets of parts.”

Custom parts printed on the Ultimaker 2+

Having saved money and time to produce plant pods and various parts, they were able to seize on an unexpected opportunity months before they expected to share their product with the world. The Farmshelf team was invited by world-renowned chef Claus Meyer (co-founder of Noma) to install a trio of fully-functioning Farmshelf units right in the heart of New York City historical icon, Grand Central Station. This experiment proved so successful that Meyer’s Great Northern Food Hall restaurant in Grand Central was able to harvest microgreens and a number of leafy greens directly from these prototypes.

Their spirits high from early successes like this Grand Central Station opportunity, they are continuing to expand upon their initial concept and innovate, part by part, towards a bright future for urban farming.