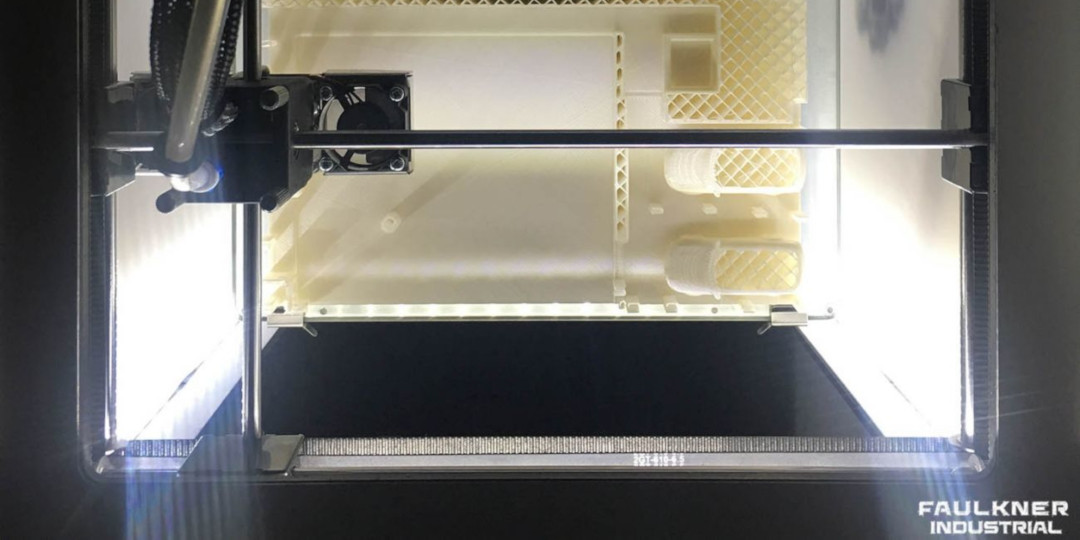

Faulkner is small but brimming with heart and passion. “Faulkner Industrial really just consists of me and my Ultimaker 2 Extended+,” Garrett confesses. Nonetheless, the speed and quality of the models pouring out of this fruitful partnership are causing the architectural community to take notice.

Faulkner Industrial: 3D printing the future of architectural design

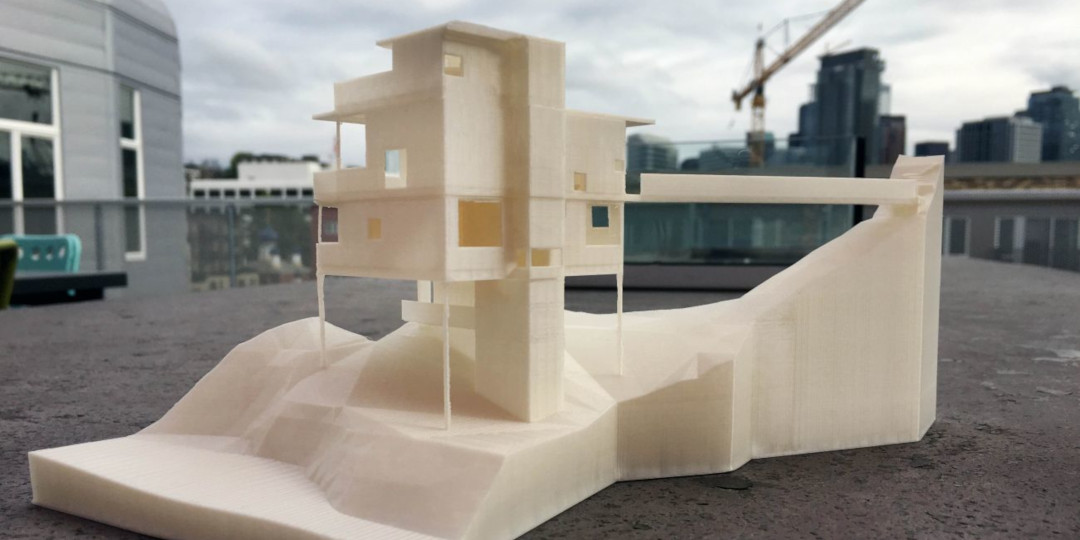

Faulkner Industrial might be a small, young firm, but thanks to a streamlined digital-to-physical pipeline and a reliable Ultimaker desktop 3D printer, they're able to deliver architectural scale models at a fraction of the cost and turnaround time compared to competitors. Because of this efficiency and approachable pricing, Faulkner offers greater benefits to their clients by through iterative model fabrication during the design process, rather than a single presentation model at the end of the process.

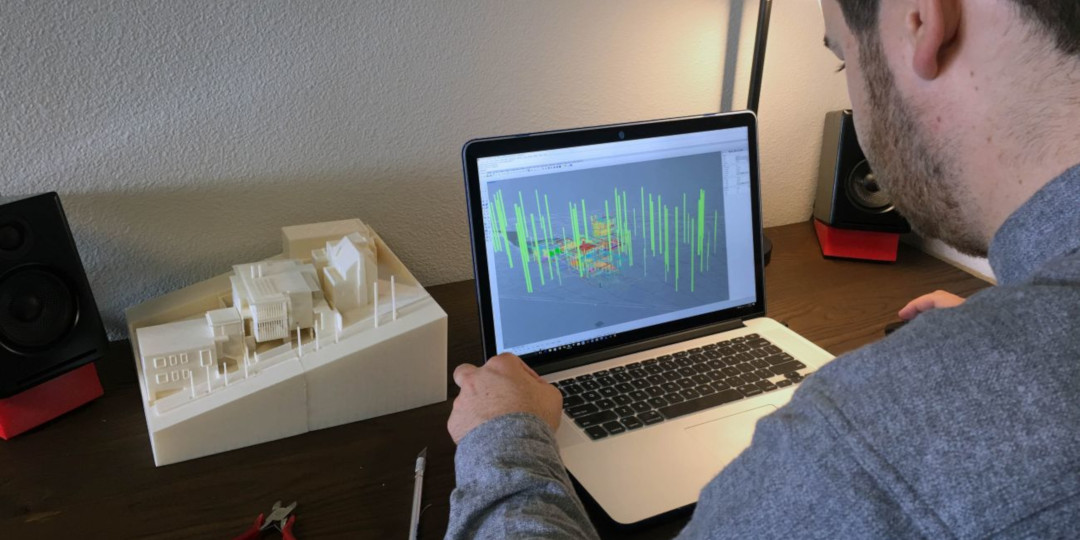

While Garrett had a foundation in CAD from his college years, it was his experience at a high-end architectural 3D printing service bureau that introduced him to the possibility of a lean solution that was focused around desktop 3D printing, rather than high-cost industrial alternatives.

By taking advantage of developments in design and job preparation software, as well as optimization best-practices from high-volume production environments, he saw that he might serve a broader range of architects more directly, not solely larger firms. “I saw a route to producing high-quality models that would exceed their expectations," Garrett says, "and allow them to bring design iteration into the physical model space.”

“Traditional architectural model making, using cork, balsa wood, and foam core is extremely labor intensive, expensive, and the turnaround time can be weeks to months.” Garrett says. It also leaves no room for design iteration, which might lead an architect and client to better results in the long run. What’s worse, Garrett says, is this “generally puts the model as an afterthought at the end of the design process, when the design is complete—as merely a presentation model for the client.”

Designing a three-dimensional object should include three-dimensional models at various stages throughout the design process, allowing the creator to place the model in the physical environment, to see what works, what could be better, and what could be different.

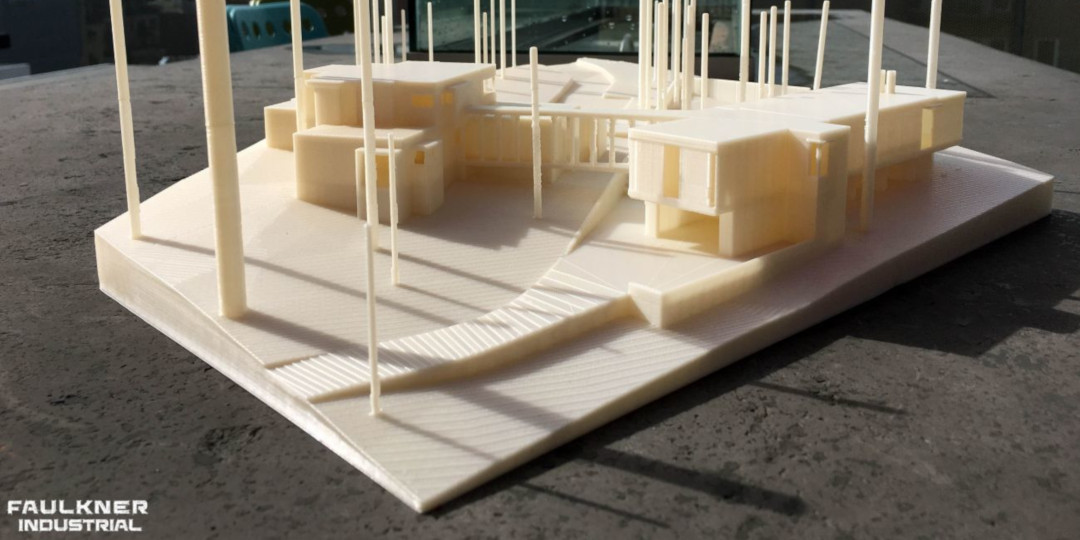

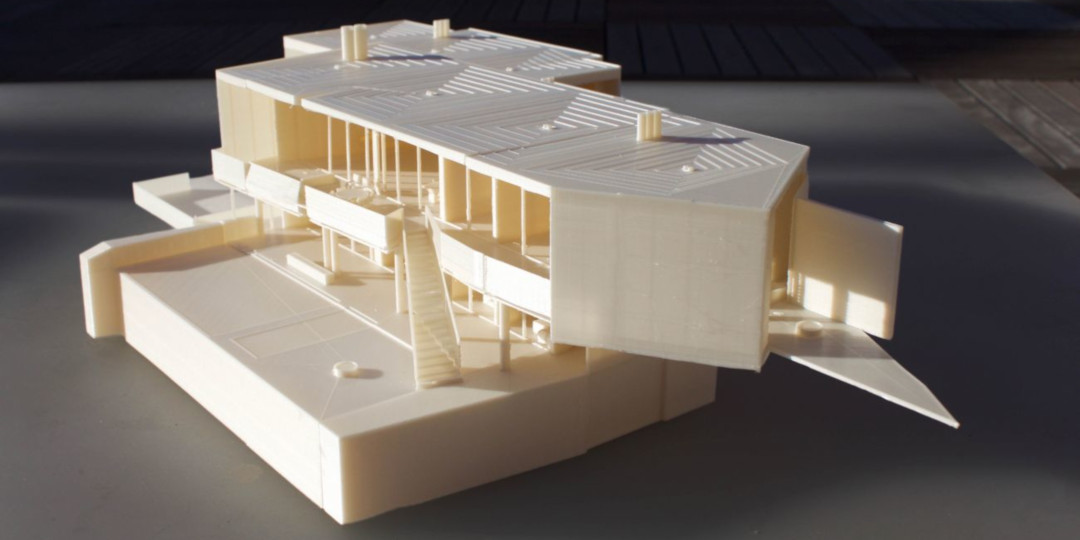

Today, Garrett runs a successful business that marries his background in industrial fabrication with constant exploration and innovation in desktop 3D printing. Garrett and his Ultimaker are able to successfully execute a range of 1:8 and 1:16 scale models that would be considered challenging projects even at large service bureaus with dozens of years of experience.

From traditional to tech-savvy

Faulkner Industrial is well-positioned to address the needs and cost requirements for a large architecture community with a single Ultimaker 2 Extended+. They are up to date with the rapid evolution of capabilities that weave together digital design and desktop 3D printing, and they have learned best practices, which have been battle-tested using high-cost, high-end industrial fabrication services.

“I produce architectural models for architects in all aspects of the design process,” Garrett says, “Whether the design is in the initial stages of development, when the design has been finalized, and everything in between.” Faulkner has strategies for leveraging the potential of desktop 3D printing at every step of the way.

Part of what enables Faulkner to exceed client expectations is how he embraces new technology. “When there is a new technology or material that comes out, I am eager to work with it, learn from it, and find ways to apply it to Faulkner Industrial,” Garrett says. Although mistakes are inevitable at first, he has found that his willingness to embrace trial-and-error has given him the confidence necessary to tackle steep challenges for modest bids that many other service bureaus might turn away.

It was this bravery to face tough fabrication challenges that convinced his father, Greg, principal architect at Faulkner Architects, to hire the newly-minted firm to produce models for a few high-profile residential and commercial projects. As with design processes, Garrett found that this sort of testing and experimenting on the job with 3D printing manufacturing strategies lead him to the hard won printing solutions that can sometimes take 3D printer technicians years to uncover organically.

As the output quality and speed quickly ramped up, Faulkner Architects were able to direct more projects to Garrett. Greg and his firm recognized that the switch to desktop 3D printing changed the range of services they might offer, resulting in happier clients.

An Ultimaker solution for 3D design

Picking which desktop 3D printing machine and collaborator to use for his operation was no challenge for Garrett. Faster and more efficient iteration meant choosing a printer that was capable, reliable, and versatile.

The choice of the Ultimaker for me was easy, as it put a new model on my desk every week to push my design further. Being able to hold a physical model of something that was just a drawing days earlier impresses clients, and when communicating with non-technical clients, it is invaluable.

Because of his background with high-end additive manufacturing solutions, Garrett had originally thought he might eventually invest in an industrial-grade printer, but the size, cost, and strict material options nudged him towards sticking with his affordable and user-friendly Ultimaker. “I had the chance to work with an Ultimaker through the maker community in San Francisco and discovered how versatile it is as a consumer level machine,” Garrett says. “I was impressed by the range of materials, the open source aspect, and the ability to print beautiful looking models at a fraction of the cost of the larger machines.”

When it comes to the overall printer design, Garrett finds Ultimaker aesthetically pleasing, and portable, which has proven invaluable for travel. He also appreciates the open-source aspect of Ultimaker, which allows Faulkner Industrial to upgrade the printer as necessary.

Perfecting the design and iteration process

Garrett feels that the additive manufacturing process has the power to change the architecture and design industry for the better. With the ability to create a 3D printed model on a small scale, an architect can meet with colleagues and clients, collect collaborative feedback, and make quick changes for an improved iteration without spending excessive time or money.

3D printing has modernized the way architects move through the design and iteration process.

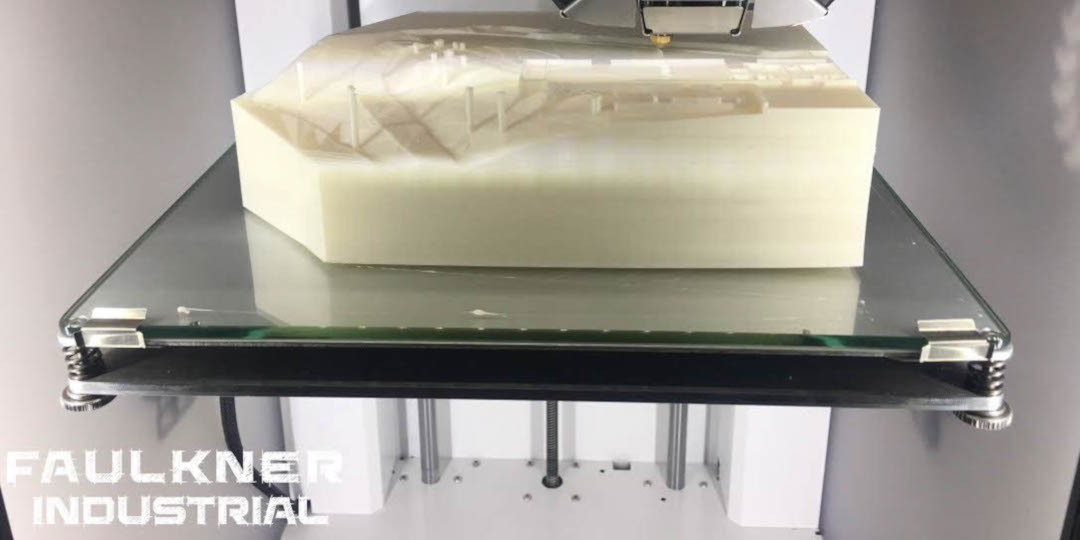

For their filament needs, Faulkner Industrial use Ultimaker PLA as it has excellent bridging properties; an important feature when printing without soluble supports. Ultimaker PLA, Garrett says, gives consistent results that clients appreciate, which is vital when producing multiple sections for one model.

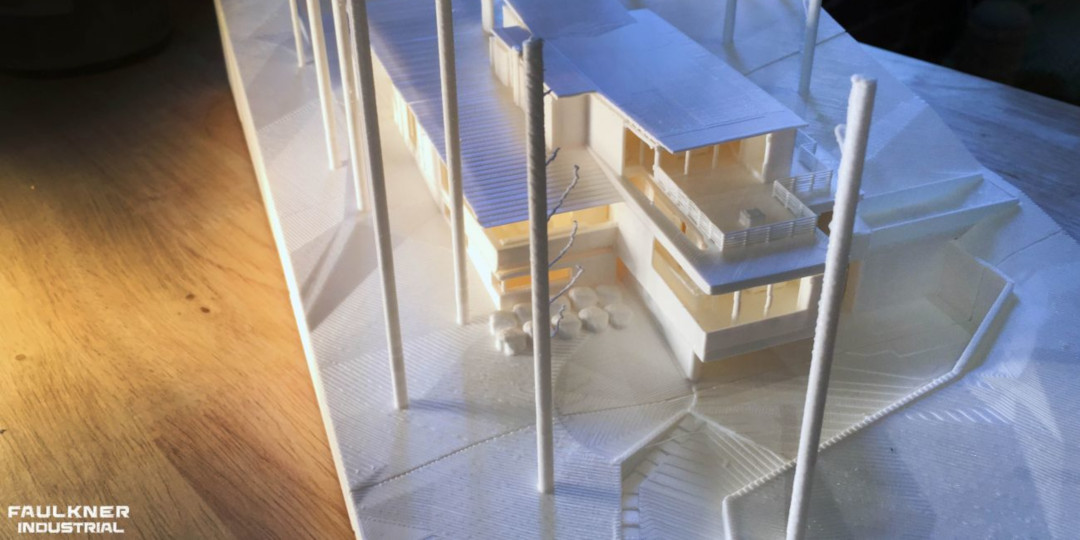

Some of Faulkner Industrial’s larger models can take anywhere from 100 to 300 hours of printing around the clock, which makes the reliability of Ultimaker another essential feature. Design flexibility is also crucial, as some models require 3D printing of the build site before the structure—a process that allows an architect to view the site in different environments with assorted lighting effects. It’s also beneficial for printing variations of the site itself, which provides base models that clients can choose from when considering the overall design.

Saving time and money where it matters most

Among all of the benefits Faulkner Industrial experiences through 3D printing, Garrett has found the most improvements in cost, time, quality, and workflow. “With a small initial investment and lower cost of model production, cost reduction is huge and allows us to produce more models,” Garrett says. Print time is a mere fraction of previous methods working with cork and balsa wood, vastly improving the experience through the iteration process.

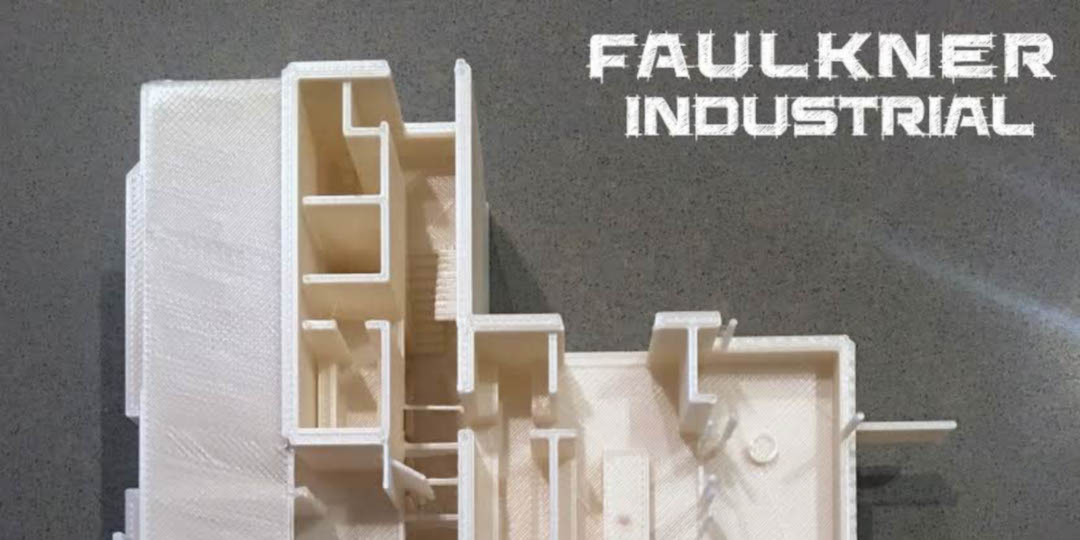

Garrett also found that the part quality is indistinguishable from large, more expensive 3D printing machines. The ability to change nozzle sizes has been beneficial when creating detailed prints, and he has seen minimal extrusion issues since upgrading their printer. When it comes to overall workflow, Garrett says that the process of printing models in smaller parts and gluing them together has forced the team to spend more time thinking about the overall design, and considering which elements to emphasize in each print iteration.

The past, present, and future of architectural design

Garrett finds that architects are amazed when one of his 3D printed models lands on their desk so quickly after delivering their files. Having grown accustomed to physical models as the product of major investment of time and energy, the cumbersome products of roundabout file translations, repairs, and even remodeling, architects are grateful for the opportunity to produce multiple iterations of a project in progress within the course of a project without puzzling through the strategies themselves. Garrett believes that by continuing to optimize processes targeting desktop 3D printing and related software in the future, that more architects can lean on services like his to lower the barrier to model production—for better design outcomes.

It’s very exciting to finally see your work in physical form; it often validates an idea or points straight at the mistakes made.

Putting in the effort to learn this technology and having patience with the process is essential, according to Garrett. Hard work pays off when designers master 3D printing and are able to produce striking, quality models of their work. By blending classical techniques with newer technologies like 3D printing, architects are already taking their designs to another level.

“Classic architectural model making methods will always have a place in an architect’s toolkit,” Garrett says. “It’s the combination of tried and true techniques with new 3D printing tech that makes for some amazing architectural models.”

Our explore pages have more information about 3D printing applications in architecture and design. Learn about 3D printing for concept models and visualization aids.