With over 150 breweries around the world, Heineken is one of the largest global producers of beer. One brewery in Seville, Spain, produces famous brands such as Cruzcampo, Desperados, Heineken, and Amstel. The beer is brewed, packed, and then shipped throughout Spain and beyond. Packaging Manager, Juan Padilla González has implemented 3D printing to increase uptime and efficiency at the Seville brewery.

Optimizing the manufacturing line

The Seville plant is able to produce up to 500 million liters of beer per year. But Heineken is always looking into new ways to improve their already impressive efficiency. That’s why they started to investigate the possibilities of 3D printing.

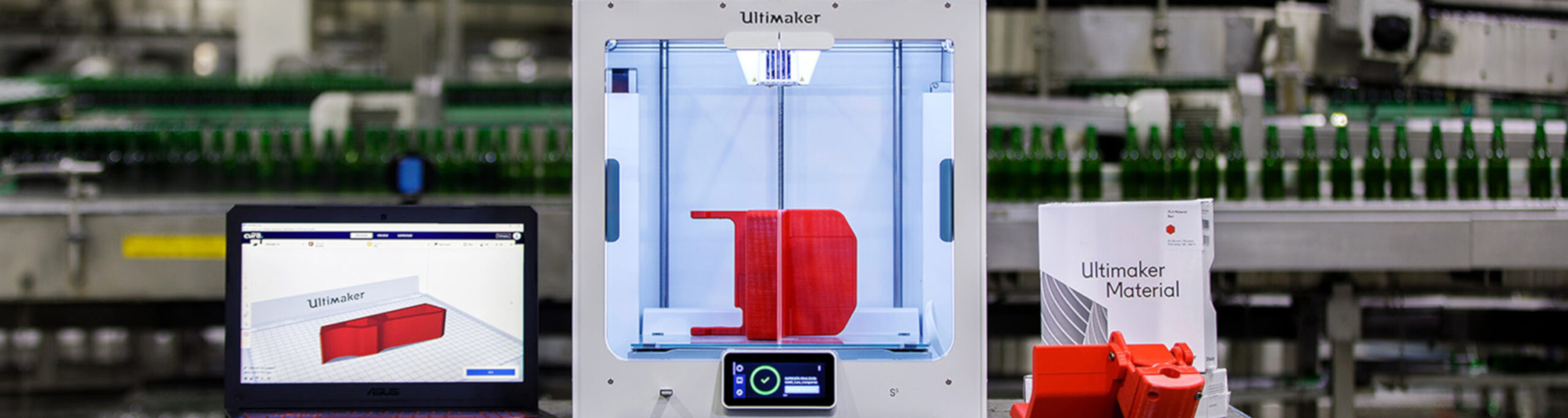

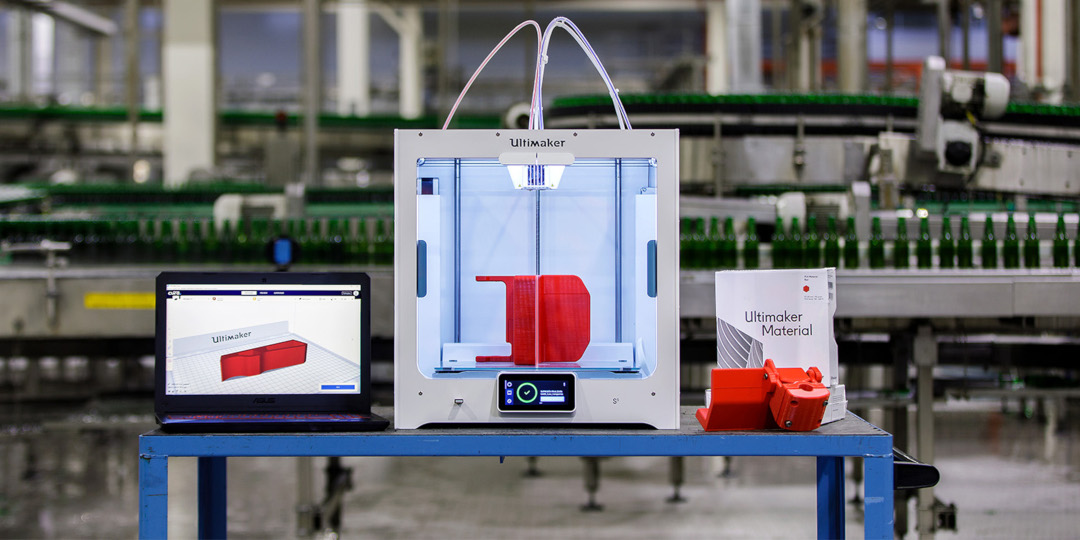

After setting up a 3D printing lab, the team set goals to improve the manufacturing process in terms of output, uptime, and safety. Heineken started looking for various methods of optimizing the manufacturing machines. They quickly realized that 3D printing gives them the flexibility and speed they need, while still being affordable and easy to implement.

We’re still in the first stages of 3D printing but have already seen a reduction of costs in the applications that we found by 70 - 90%, and also a decrease of delivery time of 70 - 90%.

Safety first

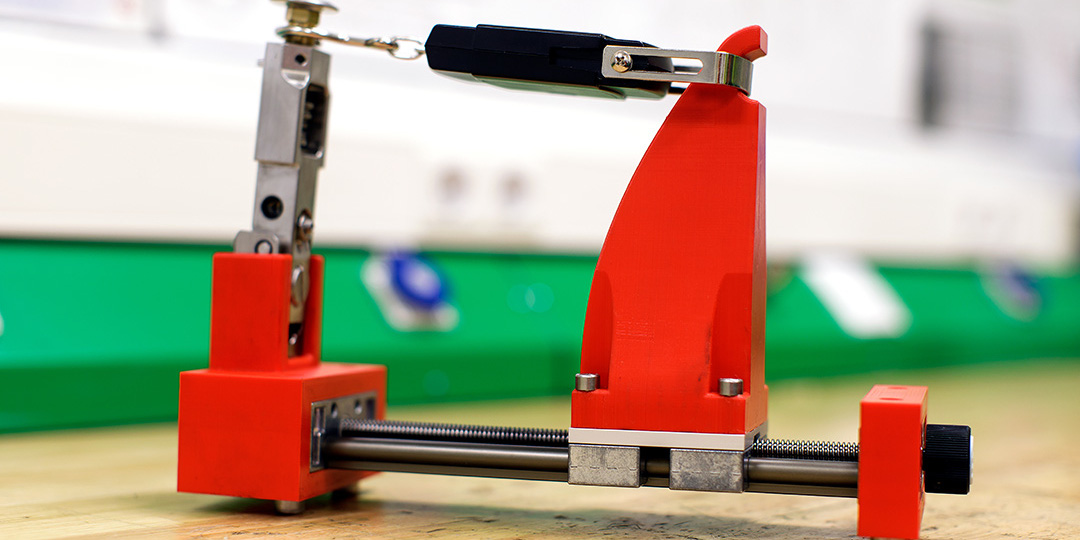

Employee safety is the top priority within Heineken, and they first designed improved safety latches, which are used during machine maintenance. These are applied to almost all the machines in the brewery. When the machines are stopped, these latches will be locked, preventing anyone from accidentally starting a machine while someone is doing maintenance.

The latches are printed in bright red to ensure their visibility. This application was not only useful, but the extra safety feature created awareness and appreciation of 3D printing among employees.

Heineken's custom 3D printed key depository

3D printed safety lock preventing machines from starting up during maintenance

Functional parts for the manufacturing line

After the initial success of the safety latches, other 3D printed application opportunities were identified.

Ideas were investigated, and new parts designed. The first of these was to print spare parts that had proven difficult to replace. Outsourcing discontinued parts or importing them is expensive and time-consuming. The team immediately saw that 3D printing these not only saved time and money, but was also able to print plastic parts which could function as structural replacements for metal parts.

3D printed functional parts remove the design constraints associated with traditional manufacturing processes

3D printed functional replacement parts can be created without stock

Optimizing part designs

The great thing about 3D printing is that it’s easy to iterate designs to perfection. An engineer can rapidly create alternative designs and test parts on-site, all while keeping cost and production times relatively low. Plastics are lighter than most metals, and are relatively strong when the right design principles and materials are applied. It’s also very easy to redesign parts to work even better, without the constraints of outsourcing.

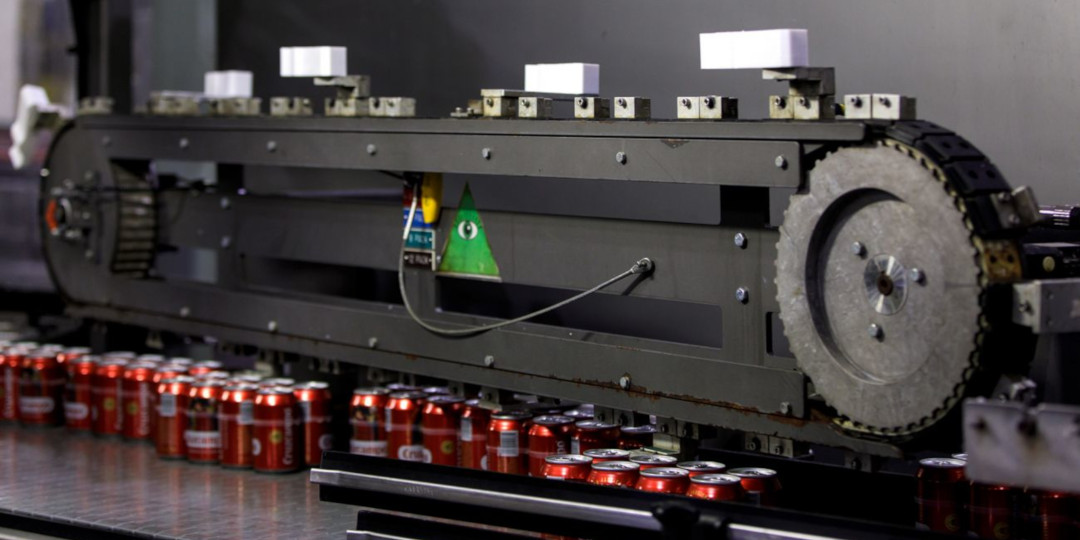

At the Seville brewery, Juan’s team was able to replace various redesigned parts with an optimized design. For example, a metal part used with a quality sensor on a conveyor belt would often knock bottles over, creating a blockage, or ejecting good bottles onto the ground. Redesigned 3D printed parts prevented this problem, saving bottles, money, and time.

Heineken optimized the conveyor belt bottle guide with 3D printed parts so that blockages are prevented

Tools for quality control and maintenance

Companies commonly 3D print custom tools, jigs, and fixtures. Heineken has made various tools to make maintenance easier and faster on their machines. These tools are usually printed from Tough PLA, which is easy to print, with similar strength and flexibility to ABS. One of these tools is the stopper tool, which loosens and tightens the columns of guiding wheels that apply bottle labels. Before adopting 3D printing, this tool had to be custom made using CNC machining.

With 3D printing, the tool’s production cost was reduced by 70%, and delivery time from three days to one day. A simple tool like the toroidal rubber cutter is printed in under an hour, which on average takes over 10 days to deliver when outsourced.

3D printed tools make maintenance easier and less time consuming

3D printing enables Heineken to create custom quality check tools

Choosing the right material

Ultimaker’s range of materials has proven useful to Heineken Spain. Many of the printed parts will endure stress, high temperatures, moisture, or numerous impacts over a long period of time. That’s why having the right materials for applications is so important.

Heineken Spain makes use of a variety of Ultimaker materials such as Tough PLA, Nylon, and semi-flexible material TPU 95A. These materials have excellent mechanical properties to withstand the wear and tear of the manufacturing line. Tough PLA is often used for pushers and tools, while Nylon is used for parts that need to function with metal parts. TPU 95A’s flexibility is ideal for bumpers and protective parts.

Parts are being developed and printed in Heineken's 3D Lab

Initial pilot plant results

After using Ultimaker S5 printers in Seville for a year, Heineken considers the pilot project a success. The results of increased employee safety, lead time, and cost reduction of all printed parts have added to that.

By 3D printing functional end-use parts for the manufacturing line on-demand, Heineken was able to optimize the functionality and on time availability. By adjusting the design of functional machine parts, Heineken has increased line efficiency. The custom tools have made performing maintenance and production changeovers considerably easier and faster for employees.

On average, Heineken sees the delivery of all the required parts is on average 80% faster than external sourcing. The costs of a printed part versus a historically sourced part are also on average 80% lower.

3D printing has proven to be a technology that helps us, brings value to us, and enables our people to work more efficiently

Global adoption of 3D printing

Seville’s success with 3D printing has not gone unnoticed. The company is setting the next steps to identify the potential of scaling the benefits of 3D printing. Additive manufacturing enables engineers and other employees to look at challenges and opportunities from different perspectives.

Designs and solutions can be easily shared over the network. This accelerates the global deployment of new applications because parts can be sent digitally rather than physically. It also avoids international freight costs and reduces transportation movement, in turn reducing environmental costs.

Want to discover how 3D printing can help your business? Download our food and beverage manufacturer's playbook to identify your own applications and get inspired by more industry-proven examples, or request a custom quote today.