Product development, and especially prototyping, is no easy game. By nature, it requires iterations, mistakes – even failures – with each misstep offering the opportunity to tweak, refine, and perfect.

This process, however, is traditionally costly. It sucks up time. It drains bank accounts. And while 'failure' in product development is to be expected, costs still add up. That’s why Idea Reality, a Hampshire, England-based product design and development studio, has turned to 3D printing.

Let’s iterate

“[The technology has shown us] a substantial improvement, not only in terms of what we’re able to achieve in the time and the cost, but also the benefit to our customers,” James Lamb, Idea Reality’s Design Director, said. “We’re finding we’re changing our initial process for prototyping for the first time. We’re doing more of a phase where we’re happy to iterate and run through a project very quickly, in one chunk of work, rather than repeatedly going back to the customer for input. This allows us to give them something that’s right first.”

Idea Reality's team of six designers is based in Hampshire, England

The bulk of Idea Reality’s clients are consumer-focused, meaning the products they eventually bring to market will be mass-produced and sold in stores. It predominantly works with individual entrepreneurs and start-ups, assisting them on the path from literal drawing board to finished product. Initial prototypes are iterated using an Ultimaker S5 printer until Idea Reality's team of six designers is satisfied the design works as well as possible. Then, in most cases, subsequent prototypes are outsourced to more closely resemble the finished product.

Most projects, James said, require between three and five iterations, depending on the product and its complexity. Many of these eventually go the route of injection-molding – an area in which 3D printing is extremely helpful, as it allows flaws and other imperfections to be spotted early in the design process, before more finalized – and expensive – steps are taken, all while using the same or similar plastics.

"The fact that we can turn around something overnight and pop [a prototype] in the post the next day is something of a game-changer," James said. "We’re able to produce things faster, with even less uncertainty and more reliability."

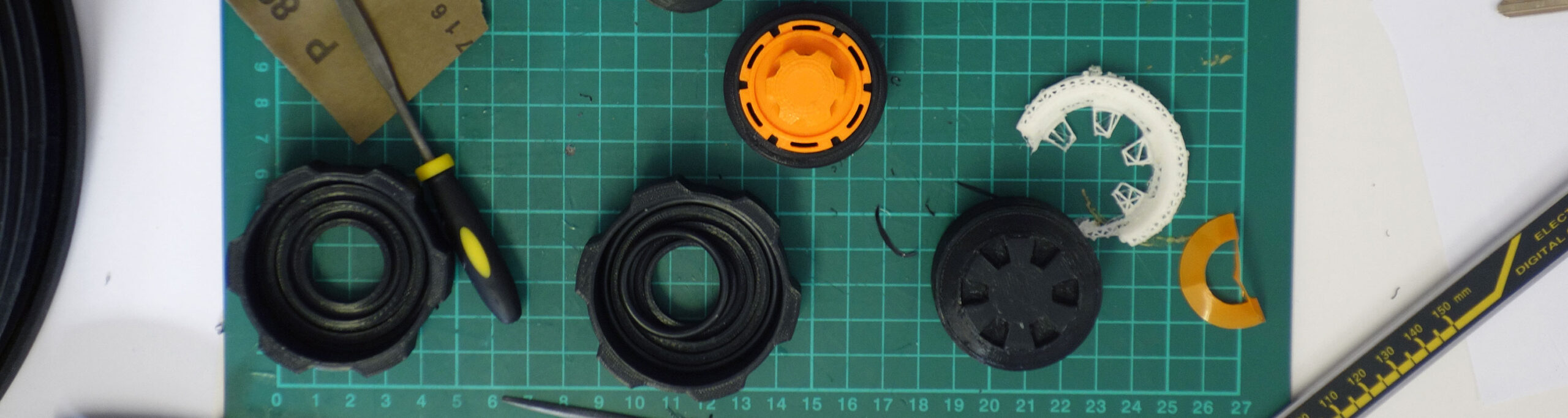

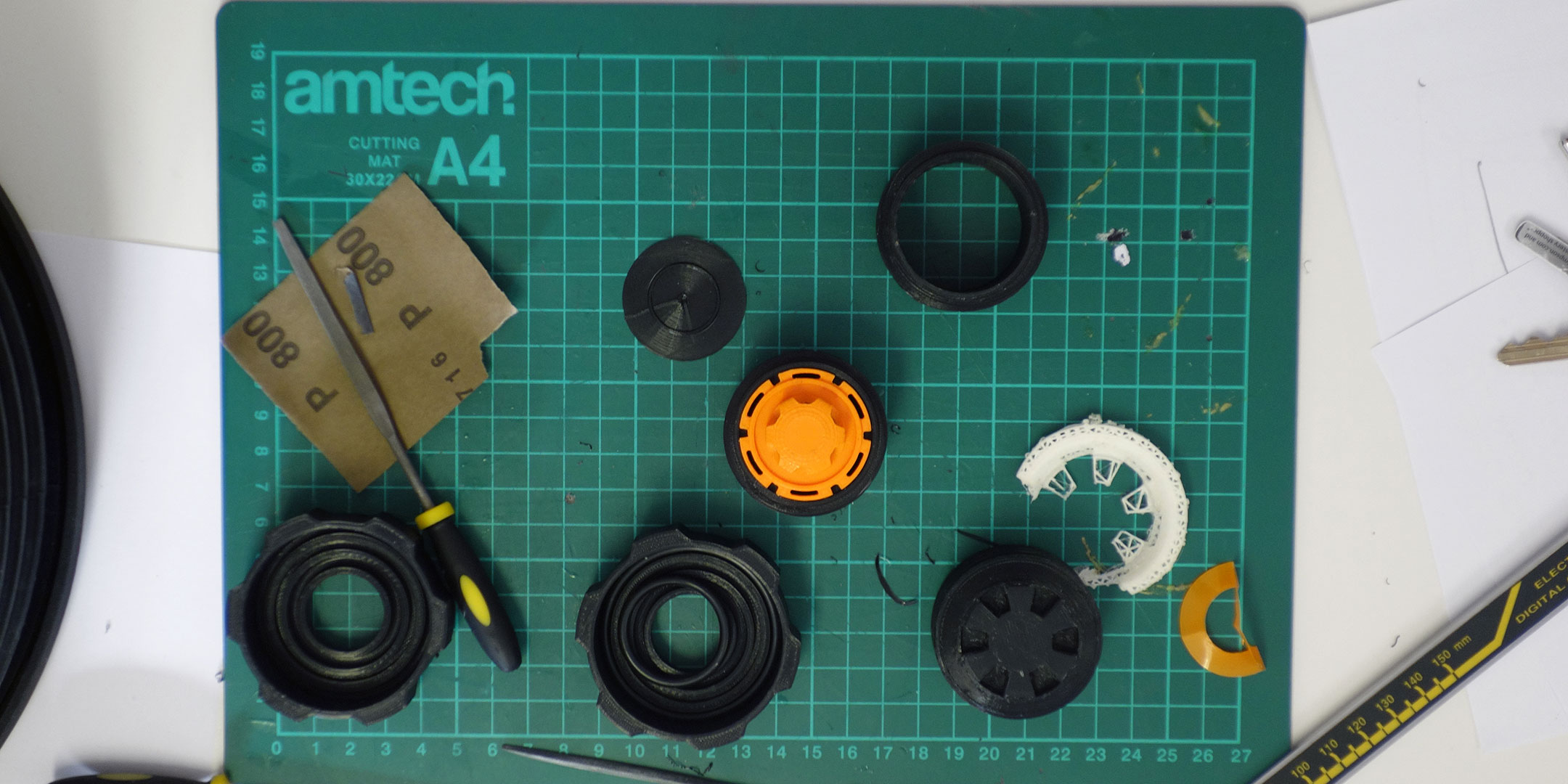

Cap valve prototypes created by Idea Reality

From print to product

Idea Reality’s clients, too, have seen their share of success. Take the teacher who developed a protractor for math students, then licensed it to one of the UK’s largest manufacturers of stationary for schools. Or the FlushBrush, an updated design of a toilet brush that is both more hygienic and effective – and which received funding on the popular British reality television series, “Dragon’s Den”.

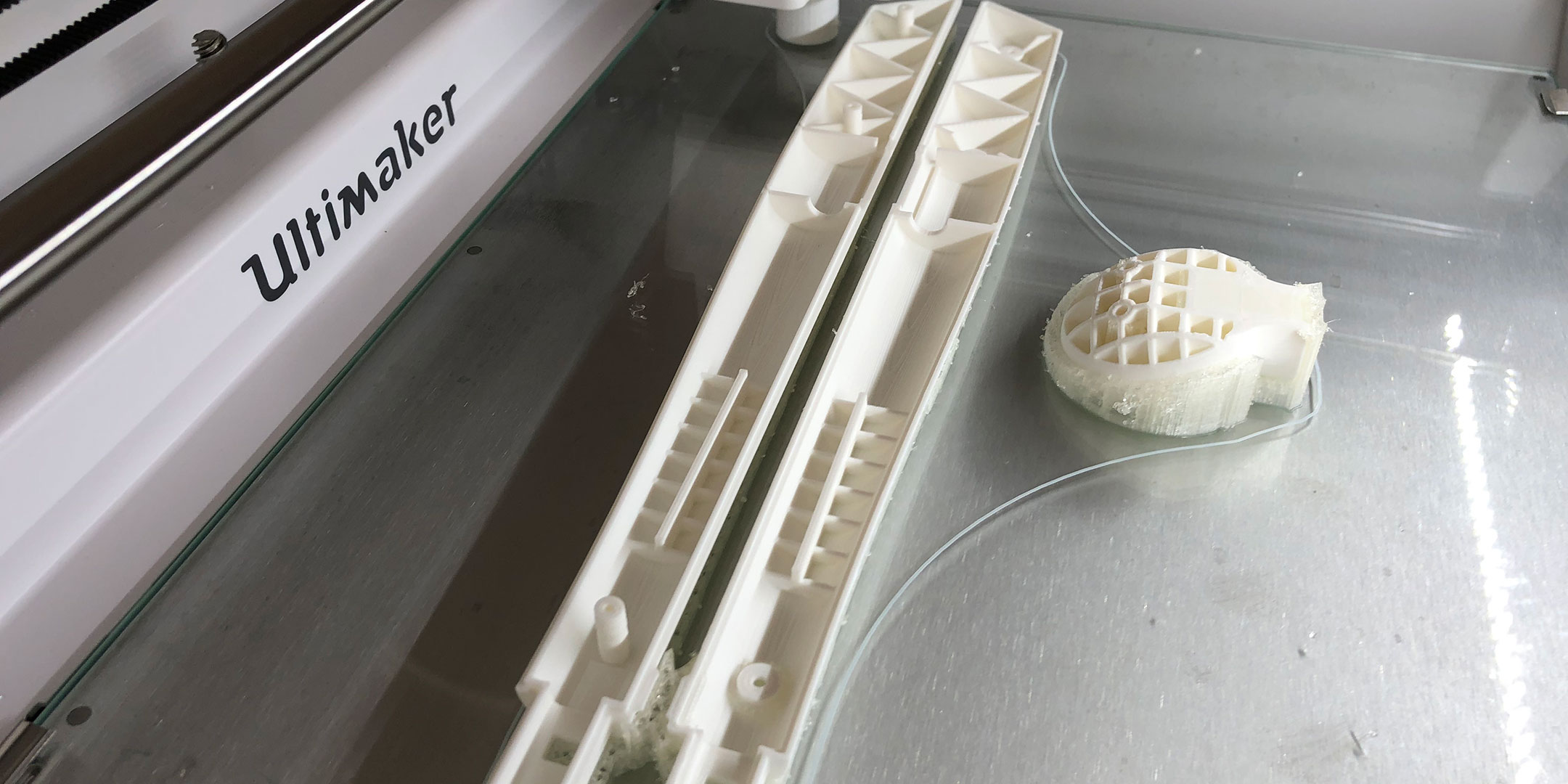

An Ultimaker S5 works to create a prototype of the FlushBrush, a redesign of a traditional toilet brush which was featured on the television series "Dragon's Den"

Using the Ultimaker S5, the Idea Reality can handle more projects in a shorter timeframe. The Ultimaker’s reliability and ease of use, James said, made it a good fit for the studio – as did its open filament system, which enables Idea Reality to discover and select the perfect material for any given job, whether it’s TPU, PP, or carbon fiber-reinforced.

"We wanted to make sure that we weren’t going to be limited to the standard hard plastics," James said. "We were keen to try other materials so that we could essentially do rubberized sections or create little light pipes or things like that. That’s one of the main reasons we went with the Ultimaker, because we felt like it could grow with us."

Electronics casing prototypes

One of Idea Reality’s most recent developments, for example, was a backpack that takes the weight off the wearer’s shoulders via an ergonomic design. That meant lots of printing and lots of changes. It also meant the prototype needed to be able to withstand and adapt to near-constant fluctuations in pressure from the wearer’s movements. Based on this knowledge, Idea Reality chose a nylon material, which is known for its high impact strength and wear resistance.

Going global

With an average of 50 clients per year, which come from across the UK as well as the world – Dubai, Spain, Sweden, Australia, India – Idea Reality is gearing up for a future in which 3D printing is heavily integrated.

"With 3D printing, language is now our main barrier, not technology," James said.

Prototypes for a product sold in the cosmetics market

As that technology advances, James said, Idea Reality will look at options in printing end-use parts, undoubtedly a benefit to its industrial clients, which currently account for about 20% of its total customer base. But for now, the studio will continue designing, iterating, refining – working with failure as a means to perfection.