Jorge Valle, 26, is the former Design Director at furniture manufacturer Cancio in Spain, now working with the multidisciplinary design company Myles Montgomery in New Zealand. We caught up with him to ask about how he uses 3D printing as part of his design process, whether prototyping new ideas for furniture or using his printer to make gifts for his mom.

In the spotlight: Jorge Valle, 3D artist and product designer

We always love to see social media posts, blogs, and videos about how people are using Ultimaker 3D printers. But when we came across Jorge Valle’s stunning video about his design (and 3D printing) process, we had to get in touch to find out more.

How did you begin using 3D printing?

It was three or four years ago, after I had been following the news about 3D printing for a long time. I decided to take the next step and get an Ultimaker 2 to start making my own stuff. I began by designing and printing small practical things, like phone cases, mounts for my camera, even a pair of tweezers. Then I incorporated 3D printing as part of the furniture design process at Cancio.

Could you describe your typical design process?

When I have an idea about a new object, I usually start sketching it in 3D using polygonal tools like Cinema 4D, which allows me to quickly create a rough shape of what I want. Once I have a basic model, I go to CAD software (Catia or Fusion 360) to start modelling the accurate piece. I use Ultimaker Cura to slice the STL file I exported from CAD, and in a few hours I get a functional prototype of the object.

That's the beauty of 3D printing. It's at this point when I try the prototype in real life, and depending on the results I usually go back to the CAD file to make small modifications in order to make it perfect.

How does this translate in practice into creating furniture prototypes?

While developing new mechanisms for our products at Cancio, we needed to test them to check that everything works properly. These mechanisms often include parts that will be made using plastic injection molding in the final manufacturing process, so 3D printing offers us a great opportunity to test those mechanisms at a low cost in no time.

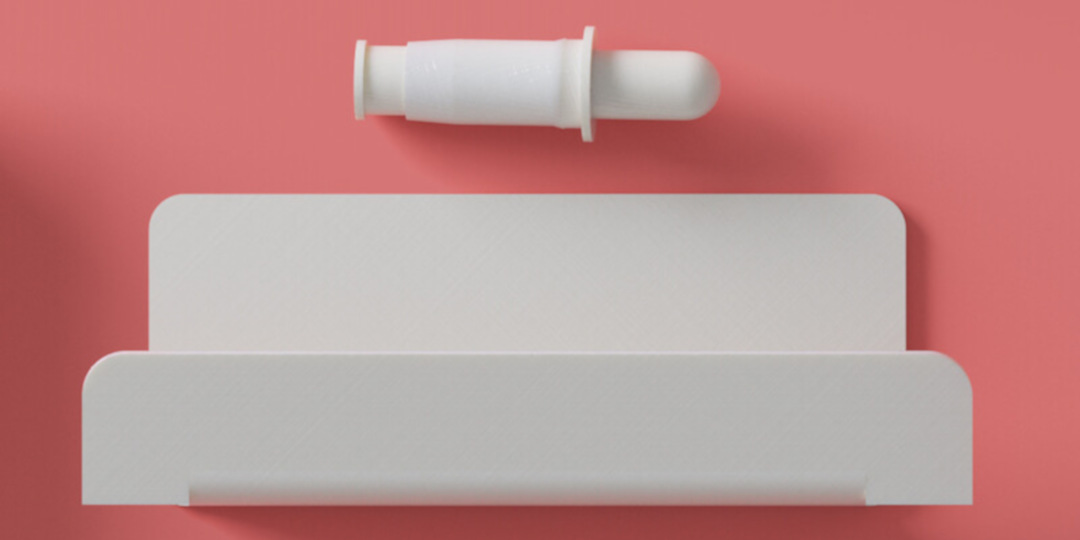

On one of our projects we needed to design a mechanism to lock an expandable table, which consisted of two different moving parts, so I started sketching some ideas, transforming them into a 3D model and printing them to test them in real life. A few hours after having the first idea I already had a functional prototype of the mechanism. 3D printing makes this process so easy and fast.

Did you find the 3D printer being used for applications beyond prototyping?

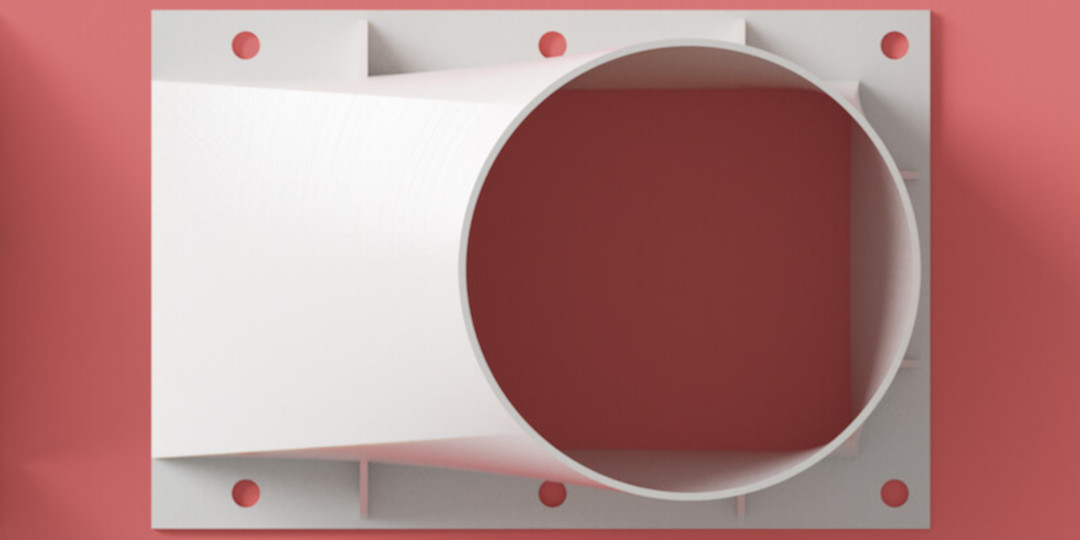

On a particular occasion, the piece that connects one of the machines in the factory to its ventilation pipe broke down. Ordering and waiting for a replacement would have cost a lot in terms of having a machine not working in a chain production. So I decided to design and print a similar piece, and with our Ultimaker we were able to reduce this downtime from days to hours, saving a lot of money and problems with our clients.

And how about outside of work?

If you are a 3D artist or a product designer, 3D printing is the perfect way to see your creations come to life.

Thanks to my Ultimaker 3D printer I was able to give the best Christmas presents to my family and friends, with customized printed creations. My mother loves cactus plants, so I decided to create a planter that I filled with soil and three different types of cactus bought at IKEA. She loved it!

As a designer, do you use any other prototyping methods?

Before we started using the 3D printer at Cancio, we used to make prototypes using expensive moulds for plastic injection, created by different companies. This was a problem, not only in terms of costs but also time. Once we sent the file we had to wait several days to have a first prototype, then repeat the process for every change in the model. With a 3D printer, everything is in-house, and you can see the results in hours instead of days, giving much more freedom to design different things and test them.

Are you working on any new projects using 3D printing?

I am currently working here in New Zealand for the multidisciplinary design company Myles Montgomery, where I am developing a project that will integrate virtual reality, architectural visualization, and 3D printing. It's a project that has been in my mind for many years, combining my skills as an industrial design engineer and 3D artist, but I can't give more details yet.

We look forward to seeing the finished product! And thanks to Jorge for sharing insights into his 3D design process with us. You can see more of Jorge’s work on his website.